Method and device for synthesizing sodium hydrosulfite

A synthesis method and hydrosulfite technology are applied in the directions of thiosulfate/dithionite/polythionite, etc., and can solve the problems of increasing safety risks, reactor explosion and fire accidents, affecting the content of synthetic hydrosulfites, etc. Achieve the effect of reducing safety risks, increasing alcohol-water ratio, and inhibiting side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for synthesizing sodium hydrosulfite, slowly dissolving solid sodium formate and sodium bisulfite in a 60-70% aqueous methanol solution at a molar ratio of 2:1, controlling the temperature of the reaction kettle to 80-85°C and the pressure to 0.15- 0.25Mpa, PH is 4.4-5.0, slowly add liquid sulfur dioxide to the reaction kettle, after stopping the feeding of raw materials, slowly add sulfur dioxide and methanol with a volume ratio of 1:1.5-3 mixed solution, at the same time, the feeding flow rate of sulfur dioxide and methanol 0.2-1.0m 3 / h, the pressure is 0.15-0.25Mpa, and the reaction temperature is 80-85°C.

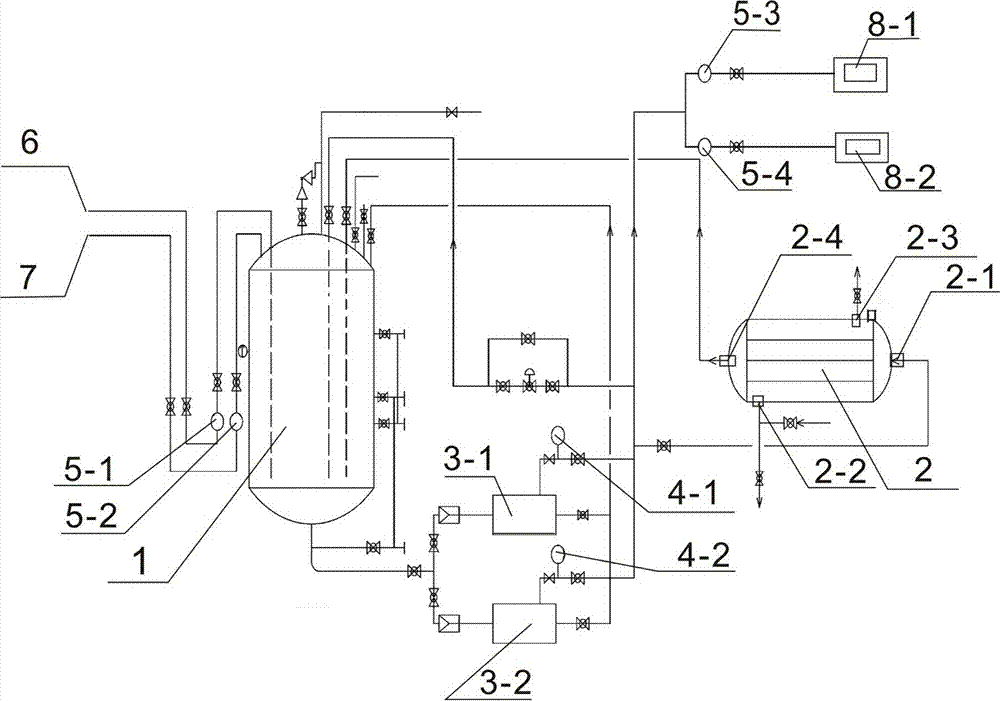

[0016] A synthesis device for hydrosulfite, comprising a hydrosulfite synthesis preparation tank 1 and an ammonia condenser 2, the bottom of the preparation tank 1 is connected in parallel with two shielded pumps 3-1, 2 and then connected to the top of the preparation tank 1; shielded pump 3 -1, 2 are connected to the inlet port 2-1 of the ammonia cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com