Guardrail device on tank top of liquid tanker

A guardrail device and technology for tank trucks, applied in the field of tank trucks, can solve the problems of high production cost, poor safety performance, inconvenient manufacturing and installation, etc., and achieve the effects of simplifying the manufacturing and installation process, reducing production costs, and facilitating lifting and swinging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present application will be further described in detail below with reference to the embodiments and drawings, but the implementation manner of the present application is not limited thereto.

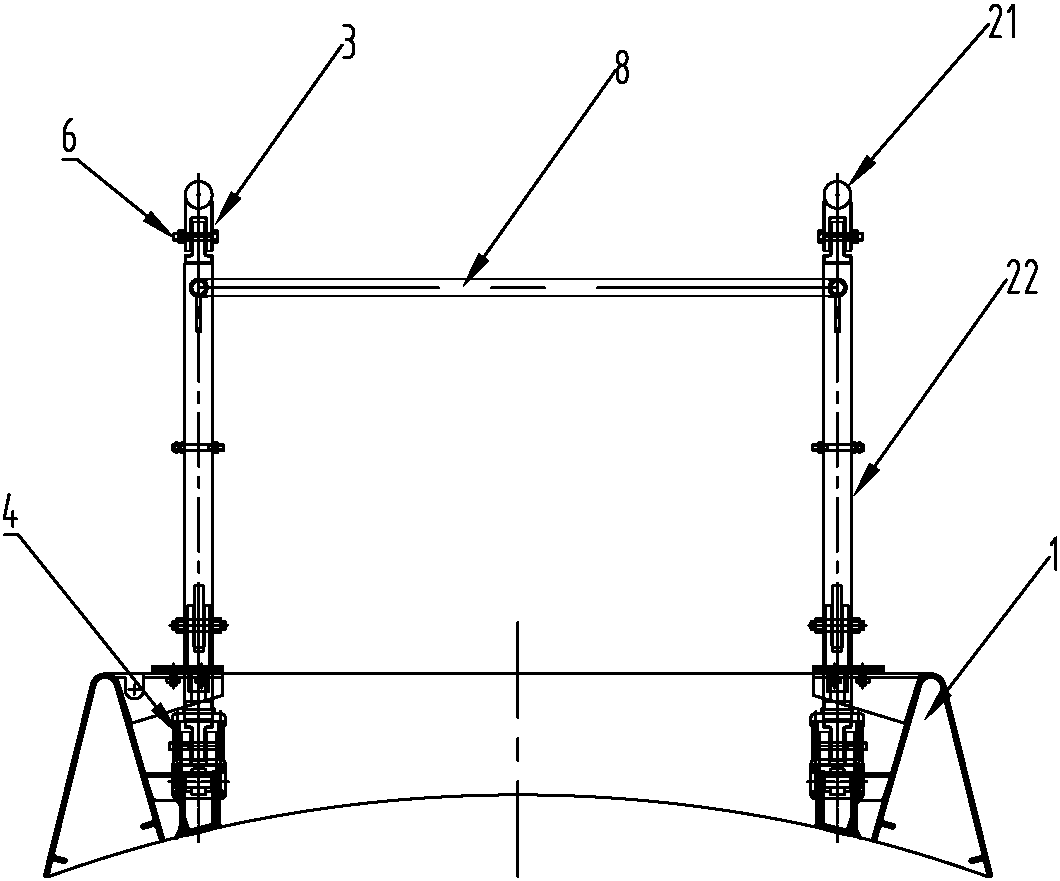

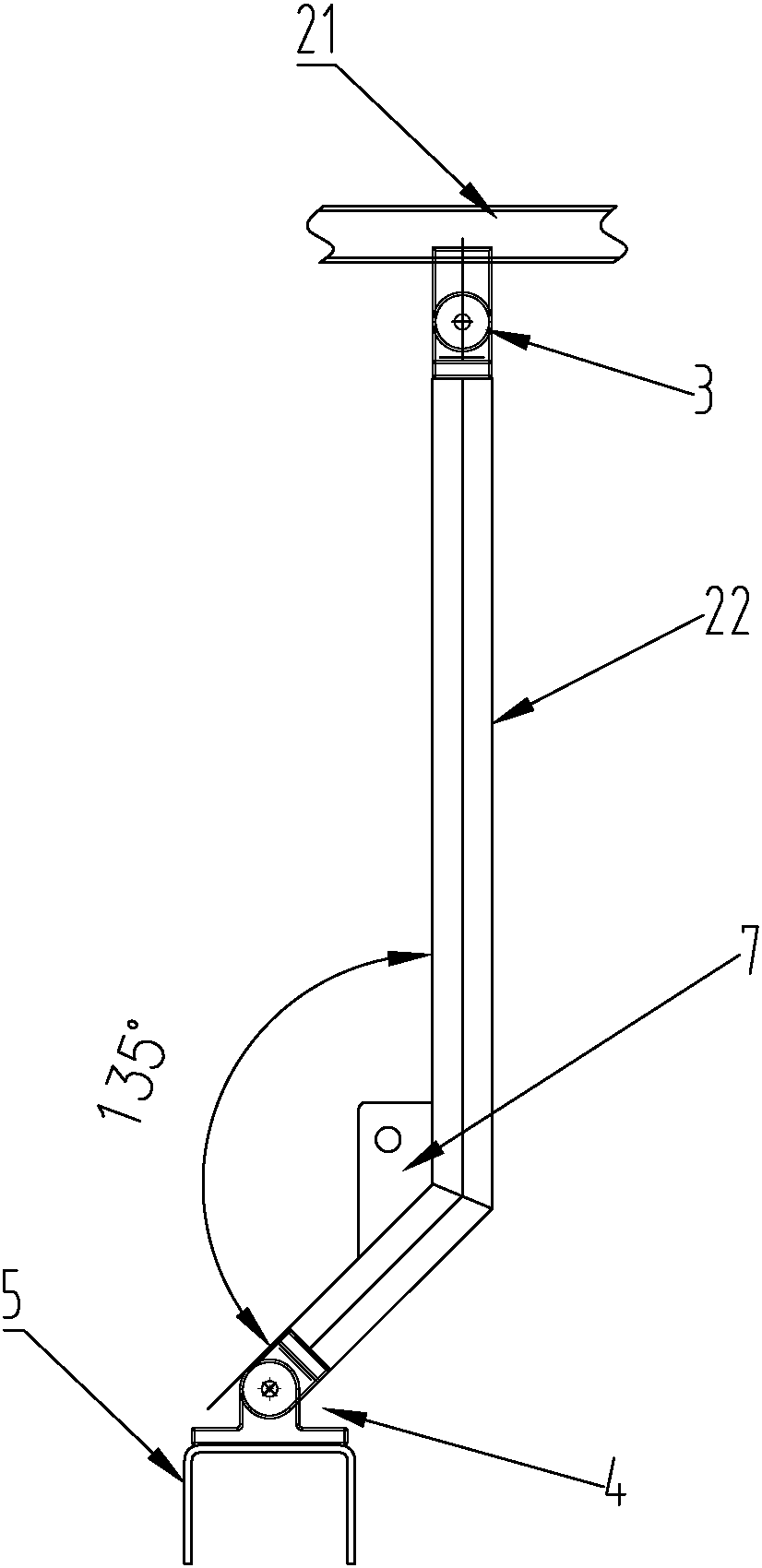

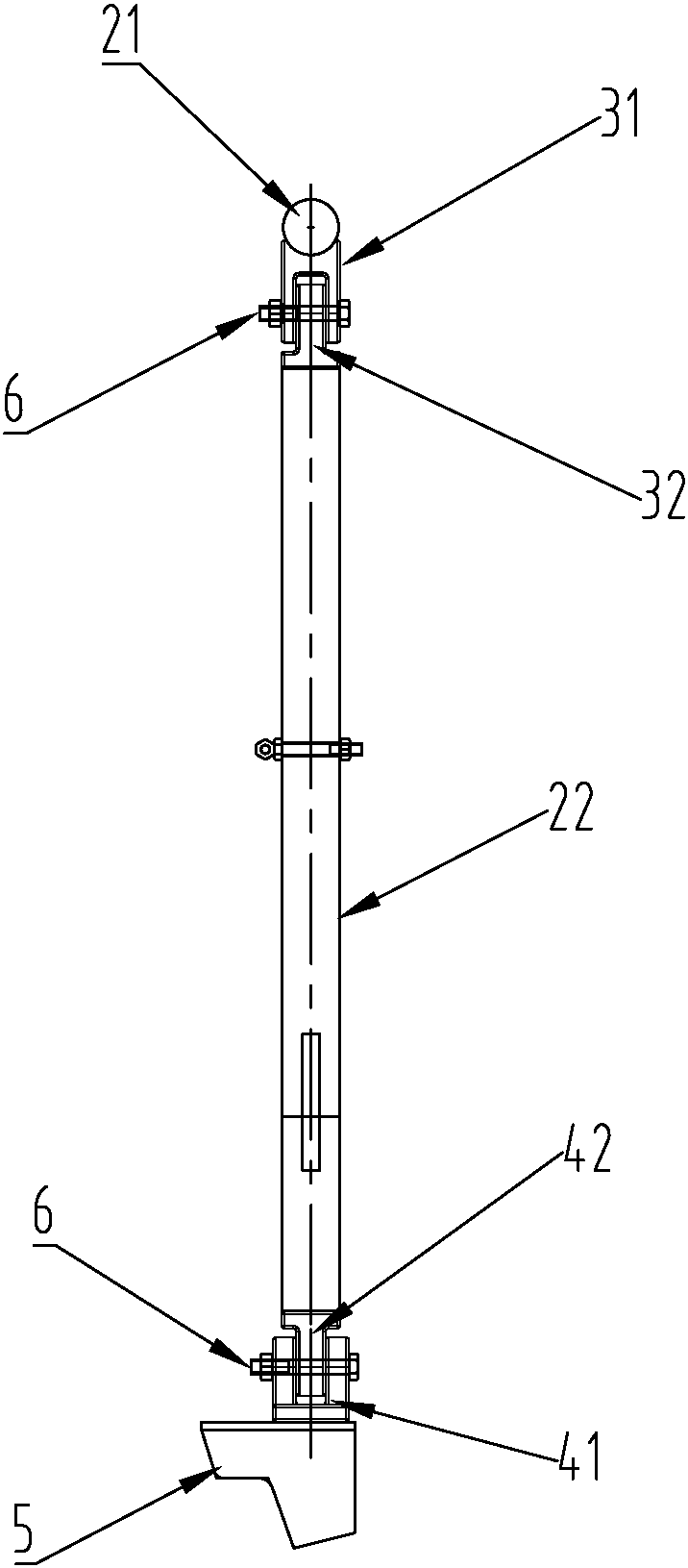

[0043] A guardrail device on the roof of a liquid tank truck according to the present application is as follows: Figure 1 to Figure 5 As shown, it includes a fence 1 installed on the top of the tank, a movable fence 2 and a supporting cylinder 9. The movable fence 2 is installed on the two inner sides of the fence 1 in the longitudinal direction. The movable fence 2 includes a cross bar 21 and several vertical bars 22. The upper end of the rod 22 is connected with the cross bar 21 through the first connection assembly 3, and the lower end of the vertical rod 22 is connected with the vertical rod holder 5 through the second connection assembly 4, and the vertical rod holder 5 is welded on the inner side of the fence 1, wherein:

[0044] Both the first connection assembly 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com