Automatic packing machine for small-caliber steel pipe

A small-diameter, steel pipe technology, applied in the field of small-diameter steel pipe automatic balers, can solve the problems of complex structure, self-weight, noise, etc., and achieve the effect of overcoming self-weight, simple structure, and flexible adaptation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

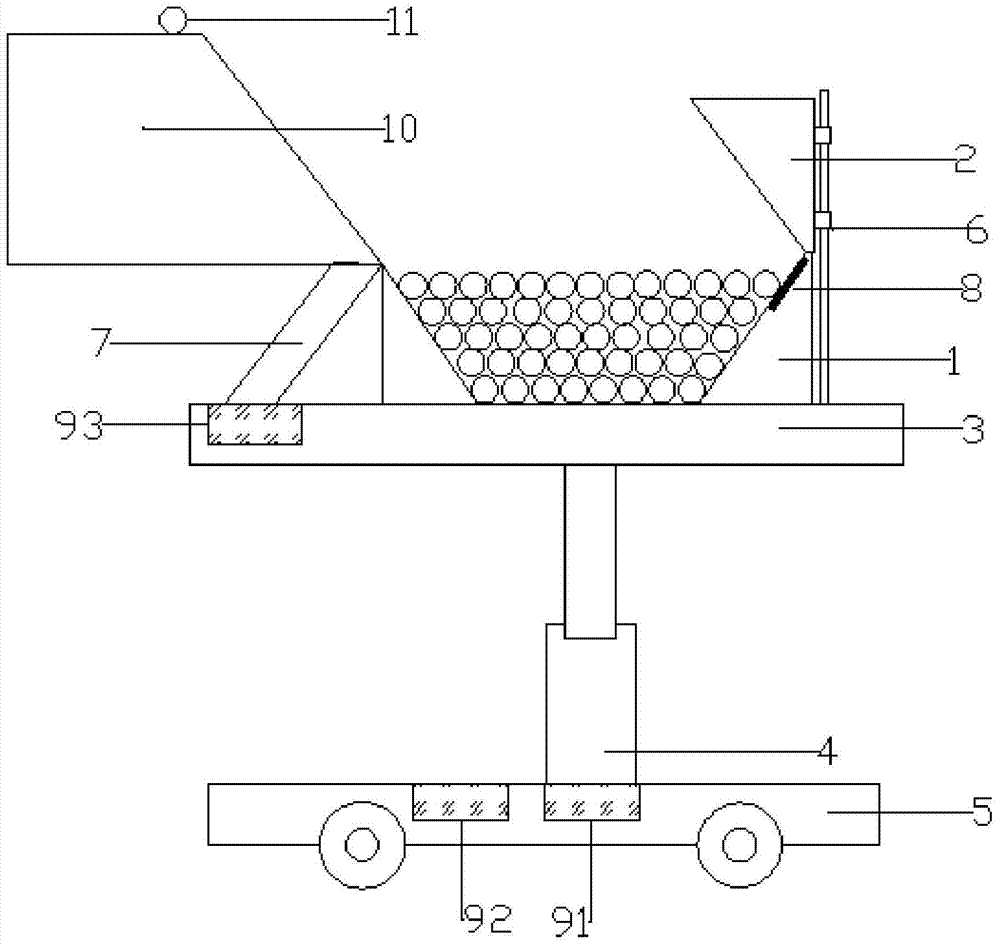

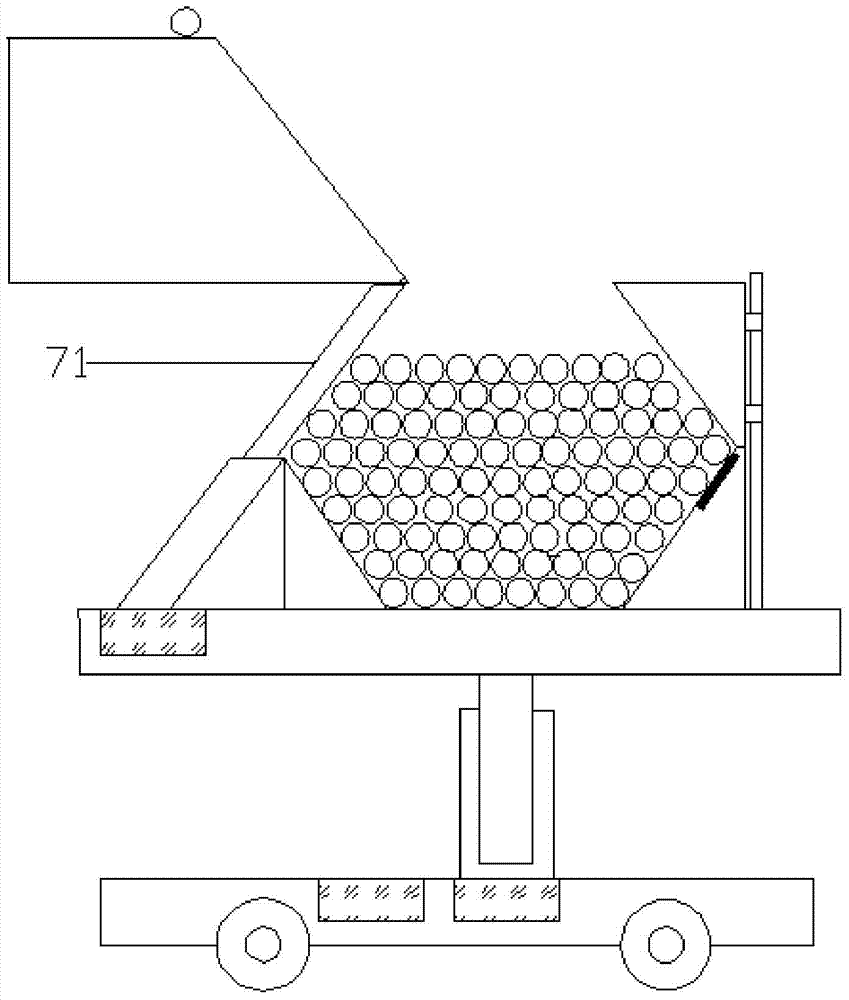

[0017] Such as figure 1 As shown, a small-diameter steel pipe automatic packing machine includes two right-angled triangle first support frames 1, a right-angle triangle second support frame 2, a fixed rod 6, a telescopic telescopic rod 7, a support base 3. The lifting device 4 and the trolley 5, each of the two first support frames 1 has a right-angled side fixed to the two ends of the support seat 3, and the fixed right-angled sides are parallel to each other or on the same straight line, The two hypotenuses are opposite; one right-angled side of the second support frame 2 is flexibly connected to the fixed rod 6, and can freely rotate around the fixed rod 6, and the other right-angled side is located above the right-angled side; The fixed rod 6 and the telescopic gear rod 7 are fixedly connected to both ends of the support seat 3; The plane of the hypotenuse is parallel; the support seat 3 is connected with the trolley 5 through the lifting device 4 .

[0018] Further, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com