Forklift body platform of large-tonnage electric forklift

An electric forklift and large-tonnage technology, which is applied to vehicle components, lifting devices, and substructures, can solve the problems of low strength and stability, and is not suitable for large-tonnage electric forklifts, so as to improve simplicity and practicability. Reasonable design, guaranteed integrity and strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

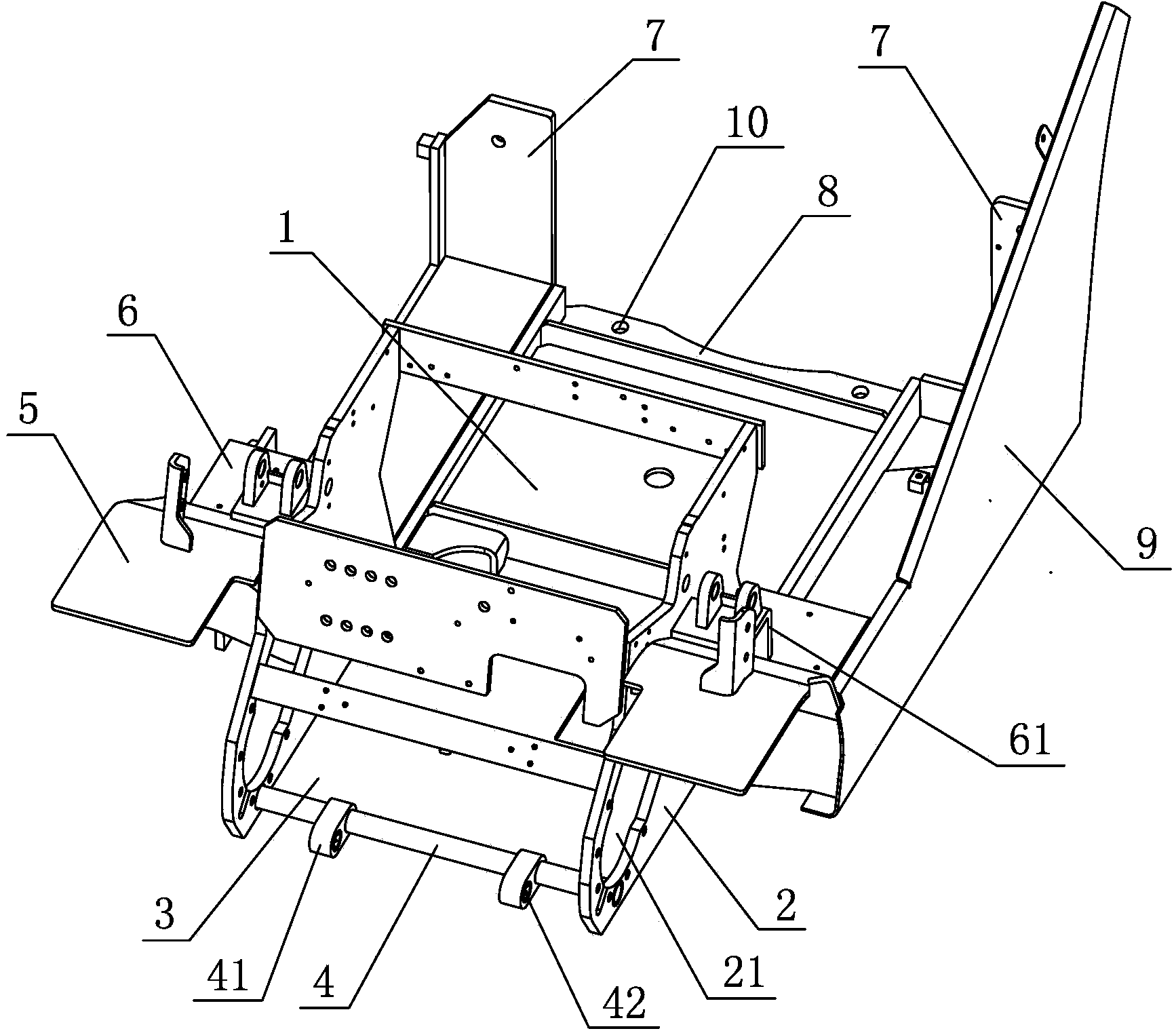

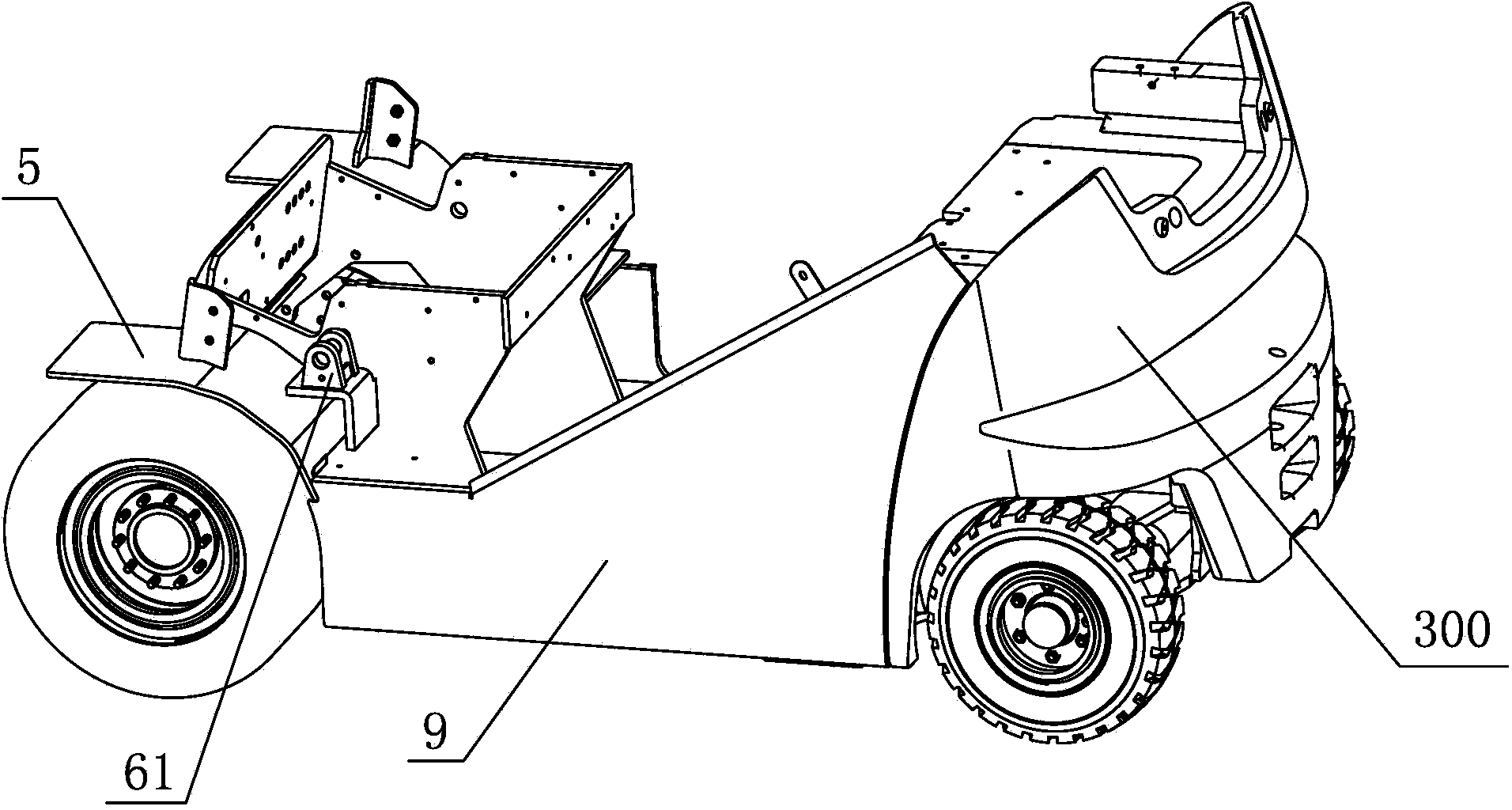

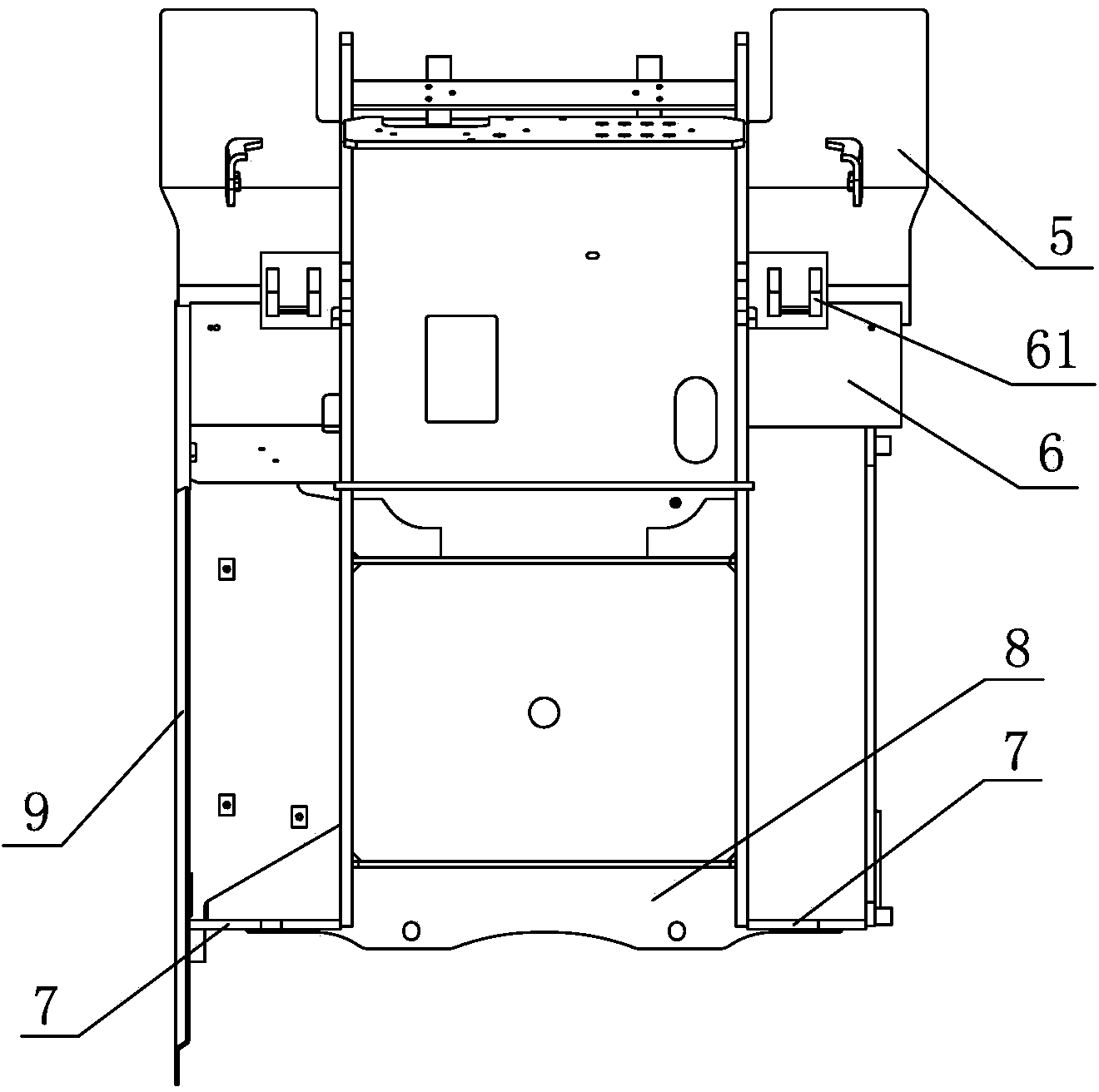

[0023] As shown in the figure, a body platform of a large-tonnage electric forklift includes a body body 1, metal plates 2 are welded on both sides of the lower front end of the body body 1, and a front bottom plate 3 is welded on the lower front end of the body body 1. The two ends of 3 are welded to the metal plate 2, and the front side of the front bottom plate 3 is welded with a horizontal axis 4, and the two ends of the horizontal axis 4 are respectively welded and fixed with the metal plate 2 at the corresponding end, and two pieces are welded on the horizontal axis 4 in a symmetrical interval. The installed mast mounting block 41, the mast mounting block 41 is provided with an oil-free bearing 42 for connecting with the forklift mast 100, the metal plate 2 is provided with a mounting hole 21 for installing the motor and the gear box 200,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com