Production method of fiber reinforced product capable of preventing electromagnetic wave interference

A manufacturing method and technology for strengthening products, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as loss, poor electromagnetic wave shielding effect, and affect appearance, and reduce production costs and time. Electromagnetic wave The shielding effect is consistent and the effect of reducing operating procedures and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

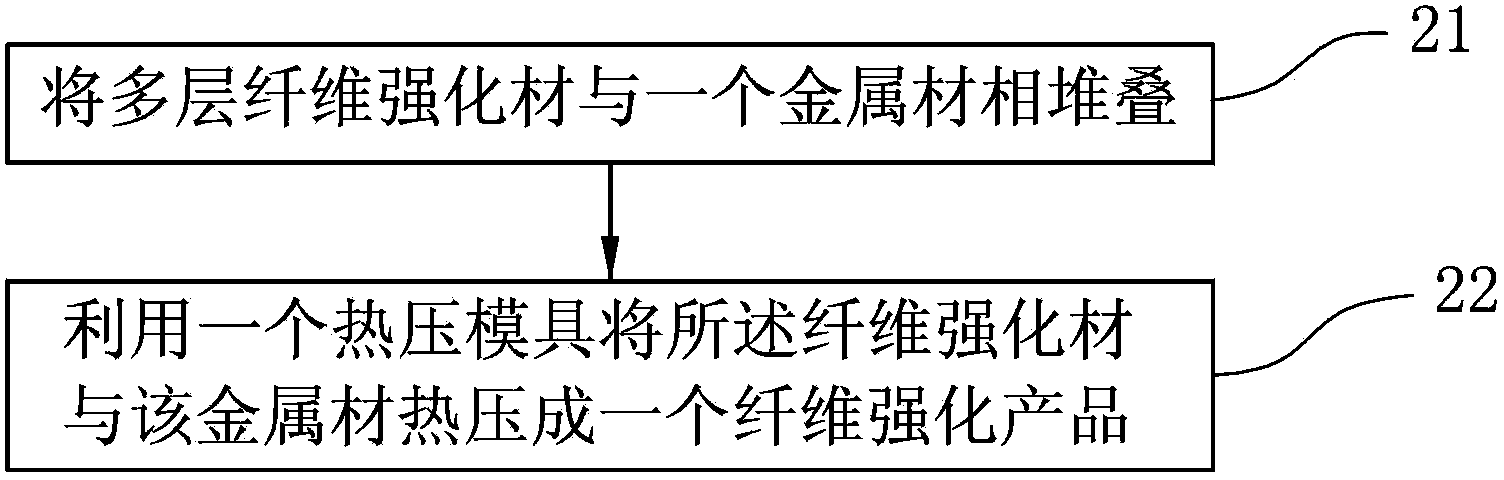

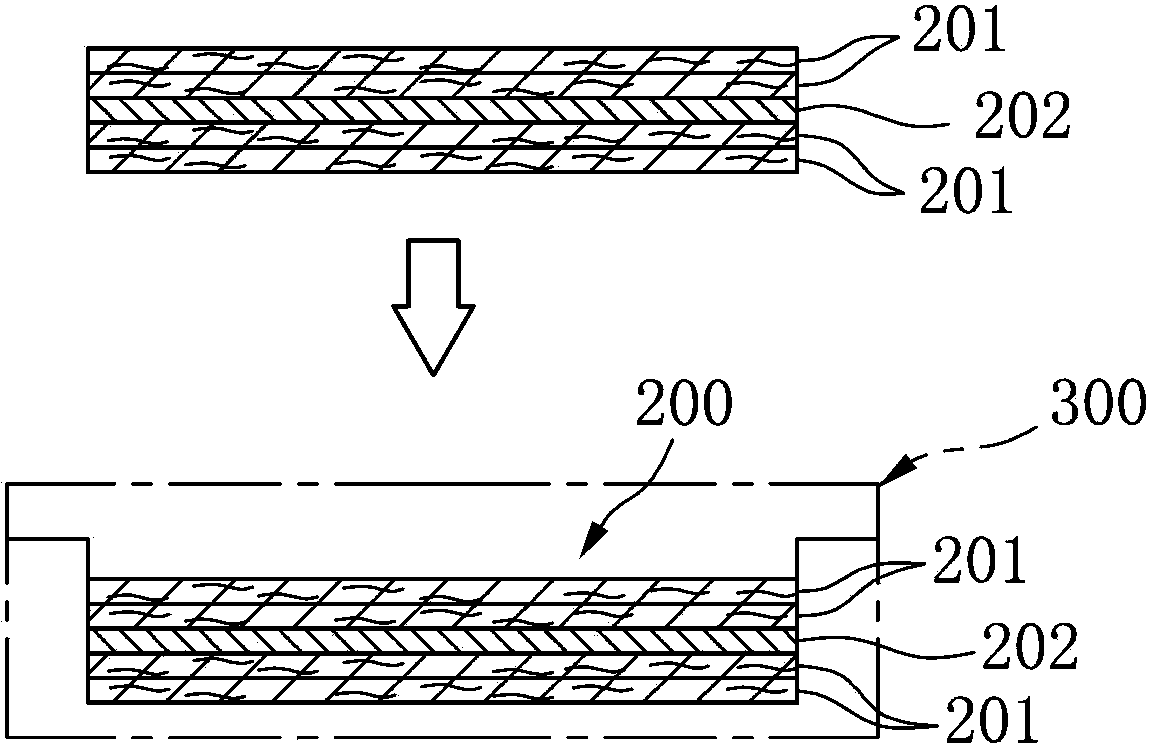

[0028] refer to figure 2 , 3 , the first preferred embodiment of the manufacturing method of the fiber-reinforced product 200 capable of preventing electromagnetic wave interference of the present invention, firstly, as shown in step 21, the multi-layer fiber-reinforced material 201 and a metal material 202 are stacked.

[0029] Next, as shown in step 22 , the fiber reinforced material 201 and the metal material 202 are hot pressed into a fiber reinforced product 200 by using a hot pressing mold 300 .

[0030] In this preferred embodiment, the fiber reinforcement 201 is a carbon fiber prepreg impregnated with epoxy resin, and the metal material 202 is located between the fiber reinforcement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com