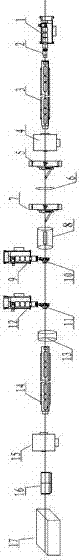

Novel compound pipeline production equipment and compound pipeline production method

A technology for composite pipes and production equipment, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of no improvement, low production efficiency of steel wire distribution and uniformity of tension force, etc., and achieve the size of tension force Uniform and consistent, saving labor and energy consumption, uniform distribution and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The production method of the present invention is illustrated by taking the fixed-length intermittent extrusion process to produce steel mesh skeleton polyethylene (PE) composite pipe as an example.

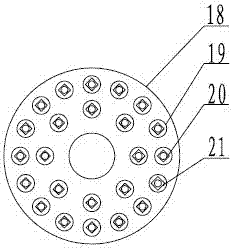

[0029] According to the required length of steel mesh skeleton PE composite pipe, wind the corresponding length of steel wire on the steel wire spindle 19 of the first winding machine 5 and the second winding machine 7, and then install the steel wire spindle 19 on the positioning shaft 20 and get ready.

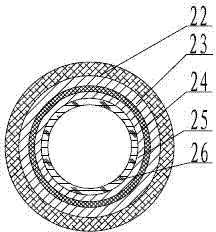

[0030] Add the PE raw material as the outer layer material of the protective layer 22, the PE raw material as the inner lining layer 26, and the special hot melt adhesive as the outer layer adhesive layer 23 and the inner layer adhesive layer 25 into the outer tube extruder 12 respectively. , In the inner tube extruder 1 and the rubber layer extruder 9.

[0031] The temperature settings for each section of the inner tube extruder 1 for extruding the inner layer material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com