Sulfuration roasting flotation process for low-grade antimony oxide ore

A low-grade technology for antimony oxide ore, applied in flotation, solid separation, etc., can solve the problems of complex impurity removal process, difficulty in improving concentrate grade, and failure to meet smelting requirements, so as to achieve good application prospects and improve Sb Grade and recovery rate, the effect of solving the low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Antimony oxide raw ore contains Sb0.5%.

[0013] Grind the ore of antimony oxide, and the particle size of the grinding product is -0.074mm, accounting for 85%. The dry powder ore is mixed with 1.0% elemental sulfur powder, and it is reduced and roasted at a temperature of 300°C for 40 minutes. The roasted product is cooled naturally, and then passed To recover antimony by flotation, first add 350g / t of lead nitrate as an activator, then add amylxanthate and butylammonium black drug combination collector with a total dosage of 100g / t (amylxanthate and butylammonium black drug According to the ratio of 2:1), add 2# oil as foaming agent,

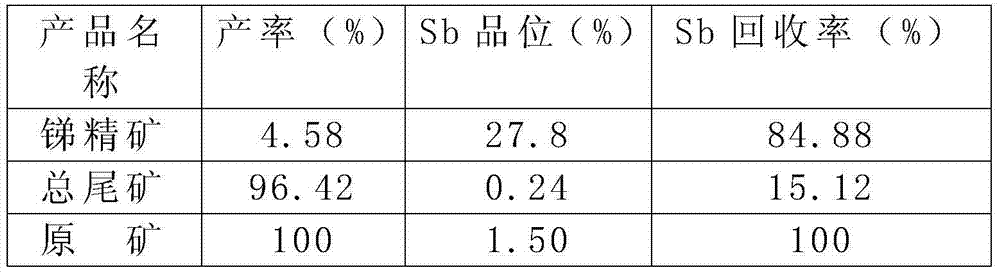

[0014] Flotation to obtain the final antimony concentrate. The test indexes are shown in Table 1.

[0015] Table 1 Antimony oxide flotation recovery index

[0016] product name

Embodiment 2

[0018] Antimony oxide raw ore contains Sb2.00%.

[0019] Grind the ore of antimony oxide. The particle size of the grinding product is -0.074mm, accounting for 65%. The dry powder ore is mixed with 3% elemental sulfur powder, and it is reduced and roasted at 400°C for 45 minutes. The roasted product is cooled naturally, and then passed To recover antimony by flotation, first add lead nitrate as an activator, then add amyl xanthate and butyl ammonium black drug combined collector with a total dosage of 200g / t (according to amyl xanthate: butyl ammonium black drug=6 :1 ratio), then add 2# oil as a foaming agent, and get the final antimony concentrate by flotation. The test indicators are shown in Table 2.

[0020] Table 2 Antimony oxide flotation recovery indicators

[0021] product name

Embodiment 3

[0023] Antimony oxide raw ore contains 0.83% Sb.

[0024] Grind the ore of antimony oxide, and the particle size of the grinding product is -0.074mm, accounting for 85%. The dry powder ore is mixed with 1.3% elemental sulfur powder, and it is reduced and roasted at 350°C for 30 minutes. The roasted product is naturally cooled, and then passed To recover antimony by flotation, first add lead nitrate as an activator, then add amyl xanthate and butyl ammonium black drug combination collector with a total dosage of 120g / t (according to amyl xanthate: butyl ammonium black drug=4 :1 ratio), then add 2# oil as a foaming agent, and get the final antimony concentrate by flotation. The test indicators are shown in Table 3.

[0025] Table 3 Antimony oxide flotation recovery indicators

[0026] product name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com