Nano-iron and graphene compound purification material and preparation method and application of nano-iron and graphene compound purification material

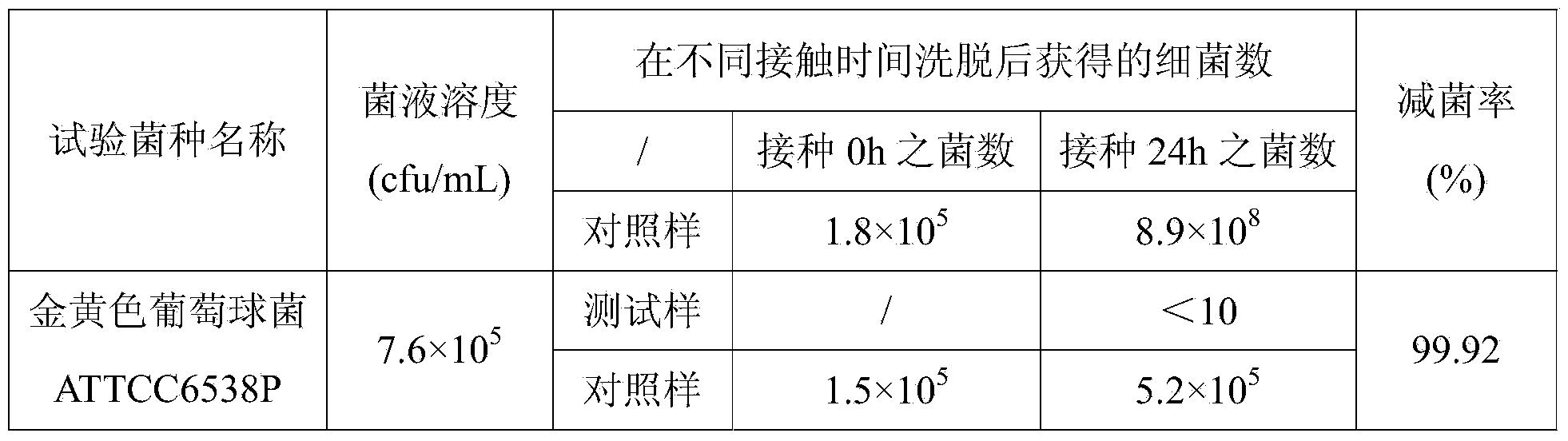

A technology for graphene composite and purification materials, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problem of not finding vacancies or dislocations, and achieve the effect of rapid removal and effective sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Dissolve 20g of ferric chloride and 0.1g of silver nitrate in 20mL of water to prepare an aqueous solution, then add 50g of graphene oxide powder into the above-mentioned aqueous solution containing iron ions and silver ions, stir ultrasonically at room temperature, and the stirring time is 2h, so that iron ions and silver ions are fully exchanged or adsorbed on graphene oxide to form a combination.

[0029] 2) The above-mentioned graphene oxide loaded with iron and silver ions was filtered to remove the residual solution, and then washed with distilled water for 3 times without residual solution, then pre-dried, and dried at 110° C. for 4 hours.

[0030] 3) Put the dried graphene oxide into the reaction sintering furnace. Under the hydrogen reducing atmosphere, the temperature is raised at a rate of 5°C / min. The sintering temperature is 600°C. After holding for 2 hours, it is cooled with the furnace, and the nano Graphene composite purification material of iron and ...

Embodiment 2

[0041] 1) Dissolve 50g of ferric nitrate and 0.5g of silver nitrate in 100mL of water to prepare an aqueous solution, then add 10g of graphene oxide powder into the above-mentioned aqueous solution containing iron ions and silver ions, and stir ultrasonically at room temperature for 10 hours. Make iron ions and silver ions fully exchange or adsorb on graphene oxide to form a combination.

[0042] 2) The above-mentioned graphene oxide loaded with iron and silver ions was filtered to remove the residual solution, and then washed with distilled water for 3 times without residual solution, and then pre-dried at 150°C for 2 hours.

[0043] 3) Put the dried graphene oxide into the reaction sintering furnace, in a carbon monoxide reducing atmosphere, heat up at a rate of 10°C / min, the sintering temperature is 300°C, keep it for 6 hours and then cool down with the furnace. That is, the graphene composite purification material loaded with nano-iron and nano-silver particles is obtained...

Embodiment 3

[0049] 1) Dissolve 30g of ferric chloride and 0.2g of silver nitrate in 50mL of water to prepare an aqueous solution, then add 10g of graphene oxide powder into the above-mentioned aqueous solution containing iron ions and silver ions, and stir ultrasonically at room temperature for a stirring time of 6h, so that iron ions and silver ions are fully exchanged or adsorbed on graphene oxide to form a combination.

[0050] 2) The above-mentioned graphene oxide loaded with iron and silver ions was filtered to remove the residual solution, and then washed with distilled water for 3 times without residual solution, and then pre-dried at 130° C. for 3 hours.

[0051] 3) Put the dried graphene oxide into the reaction sintering furnace, raise the temperature at a rate of 8°C / min in a hydrogen reducing atmosphere, the sintering temperature is 400°C, keep it for 3 hours and then cool down with the furnace. That is, the graphene composite purification material loaded with nano-iron and nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com