Passive tire power generating device and tire parameter detecting system

A power generation device and tire technology, which is applied in tire measurement, tire parts, generators/motors, etc., can solve the problems of high cost of surface acoustic wave materials, difficulty in testing tire coil performance, and difficulty in meeting detector requirements, etc., to achieve power supply The effect of stability, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] In order to better understand the present invention, the present invention will be further described in detail below by taking the passive tire power generation device applied to the tire pressure detection system as an example.

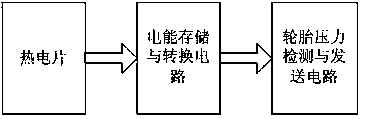

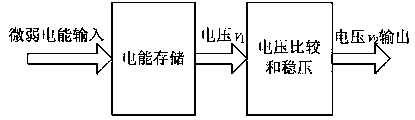

[0029] see figure 1 , a passive tire pressure detection system, which belongs to the direct tire pressure monitoring system; includes a parameter sensor (such as a pressure sensor), a wireless transmitter and a central receiver module; the parameter sensor is installed in each tire to measure the air pressure of the tire, using The wireless transmitter sends the pressure information of the tire from the inside of the tire to the central receiver module, and then displays the tire pressure data; the parameter sensor and the wireless transmitter are powered by the power generation device installed on the tire; the power generation device It is composed of thermoelectric collection sheet, electric energy sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com