Triaxial impact ground pressure true simulation test system

A simulation test system, technology of impact ground pressure, applied in the direction of testing material strength by using one impact force, testing material strength by applying stable tension/compression, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

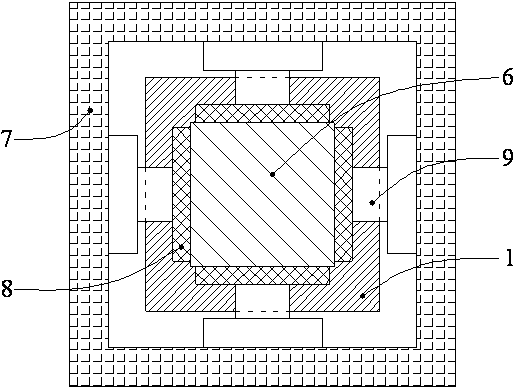

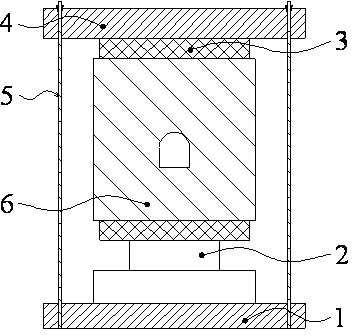

[0019] combined with figure 1 and 2 , a ground shock compaction triaxial simulation test system is characterized in that it includes a flexible loading unit, a confining pressure loading unit and an impact loading unit.

[0020] The flexible loading unit includes a base 1, a loading cylinder 2, a servo oil source, a loading backing plate 3, a reaction plate 4, and a reaction steel strand 5; one end of the loading cylinder 2 is supported on the base 1, and the other end is on the test Part 6 applies an axial load; the left and right sides of the reaction force plate 4 are respectively provided with through holes for connecting the reaction force steel strands 5; there are multiple reaction force steel strands 5, and one end of any one is fixed on the base, It is fixed on the counter force plate and is used to exert counter force on the counter force plate, and it will not produce a supporting effect when the counter force plate 4 is impacted. When the test piece 6 is damaged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com