Rolling bearing fault feature extraction method based on independent component analysis and cepstrum theory

An independent component analysis and fault feature technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of increasing the difficulty of fault feature extraction, increasing the number of modulation sidebands, and difficulty in extracting fault information, so as to facilitate the separation and extraction of target fault signals, Improve diagnostic accuracy and real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the following examples are only used to illustrate the present invention, but are not intended to limit the protection scope of the present invention.

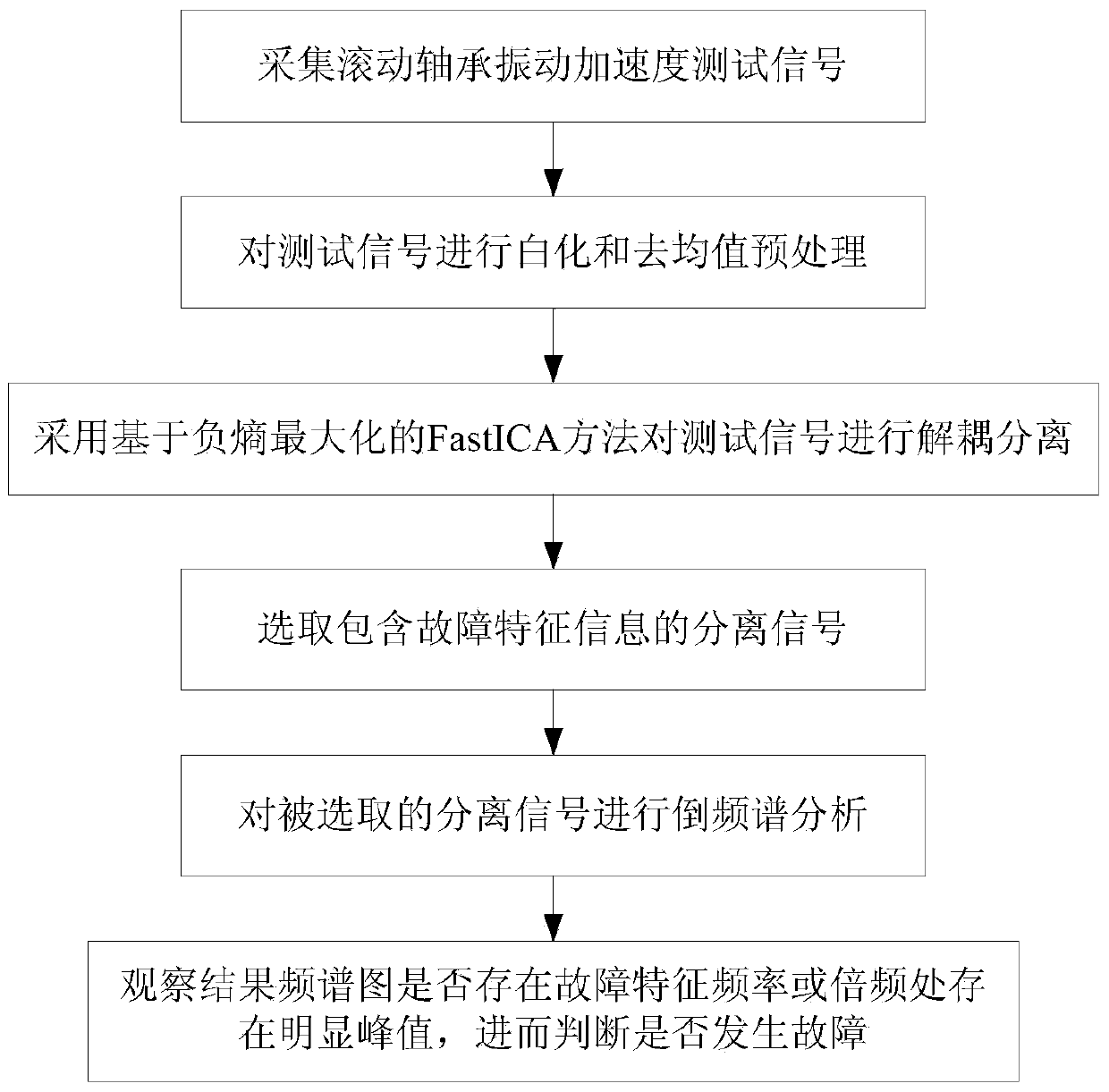

[0017] A flow chart of a rolling bearing fault feature extraction method based on independent component analysis and cepstrum theory in an embodiment of the present invention is as follows figure 1 shown, including the following steps:

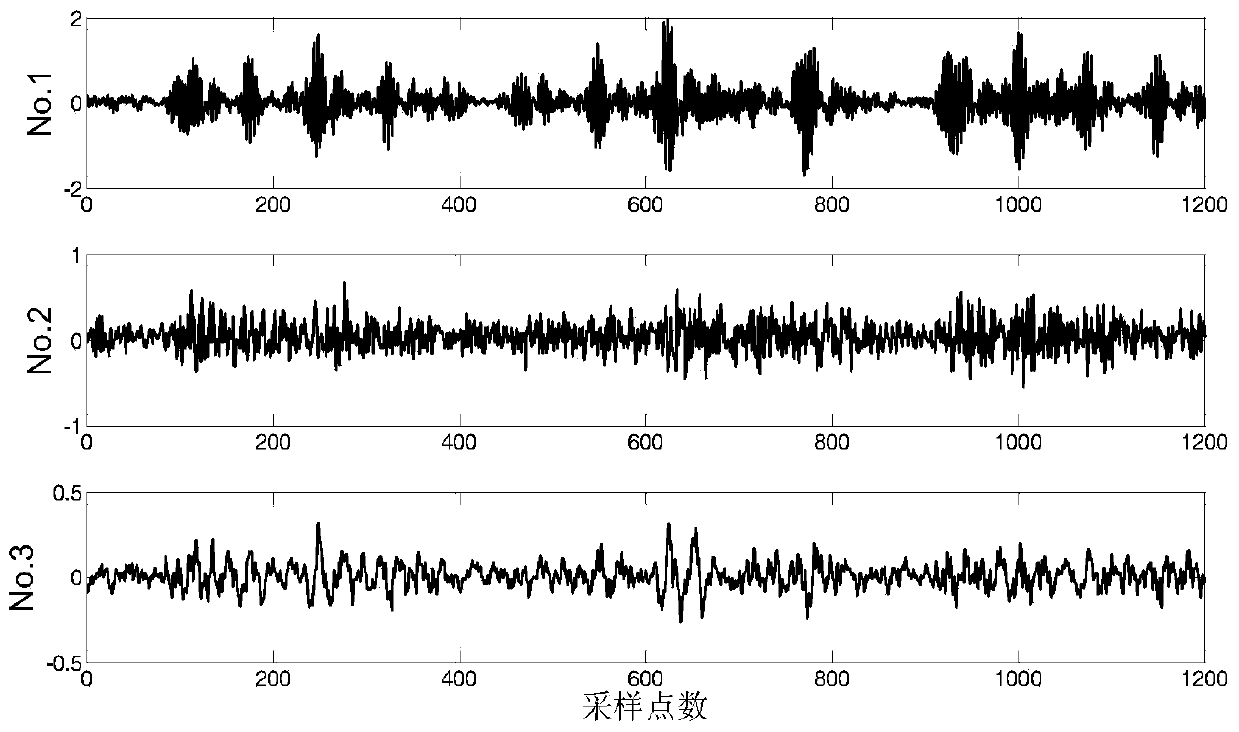

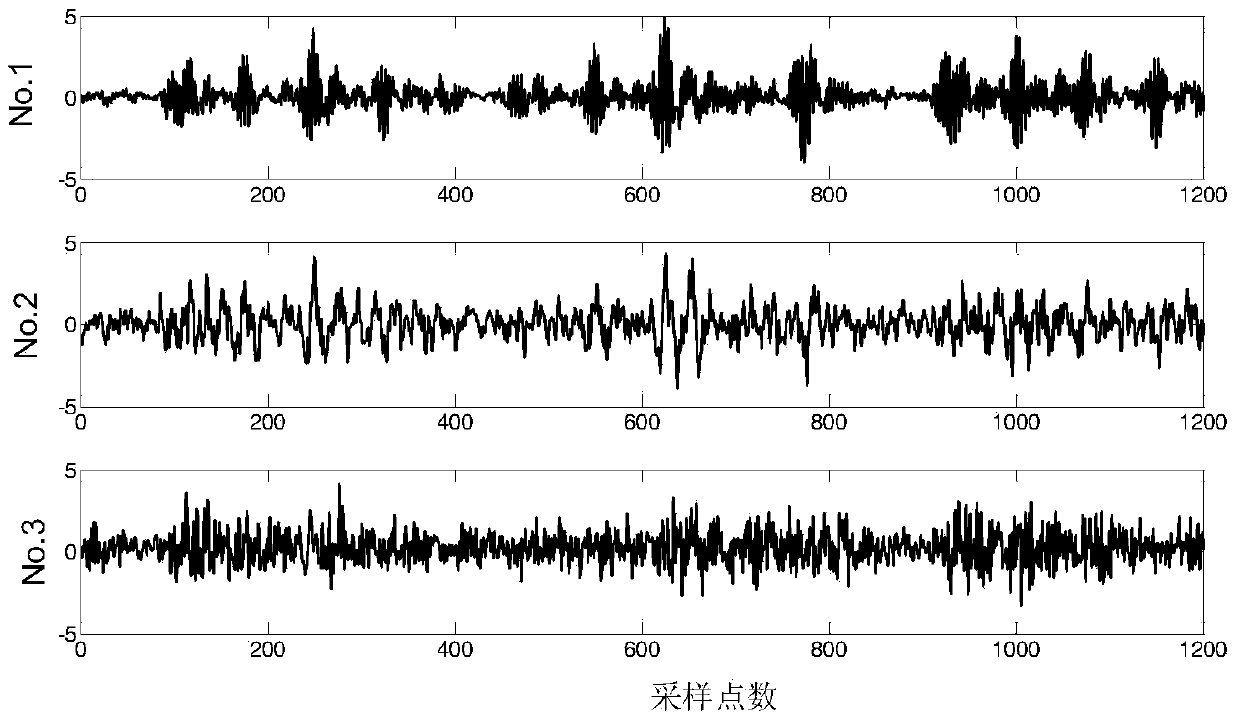

[0018] 1) The acceleration sensor is used to obtain the vibration acceleration test signal of the rolling bearing. In the present invention, three acceleration sensors arranged at different positions of the rolling bearing are used to obtain three vibration acceleration test signals.

[0019] 2) The FastICA method based on negative entropy maximization is used to decouple and separate the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com