Online slagging method and device of walking-beam furnace

A heating furnace and walking beam technology, applied in the field of on-line slag slagizing method and device of walking beam heating furnace, can solve the problem that the furnace bottom mechanical equipment cannot be guaranteed to work normally, the opening space of the movable column is blocked, and the walking stroke of the movable beam is hindered, etc. problem, to achieve the effect of excellent slag removal effect, ensure normal operation, low production cost and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

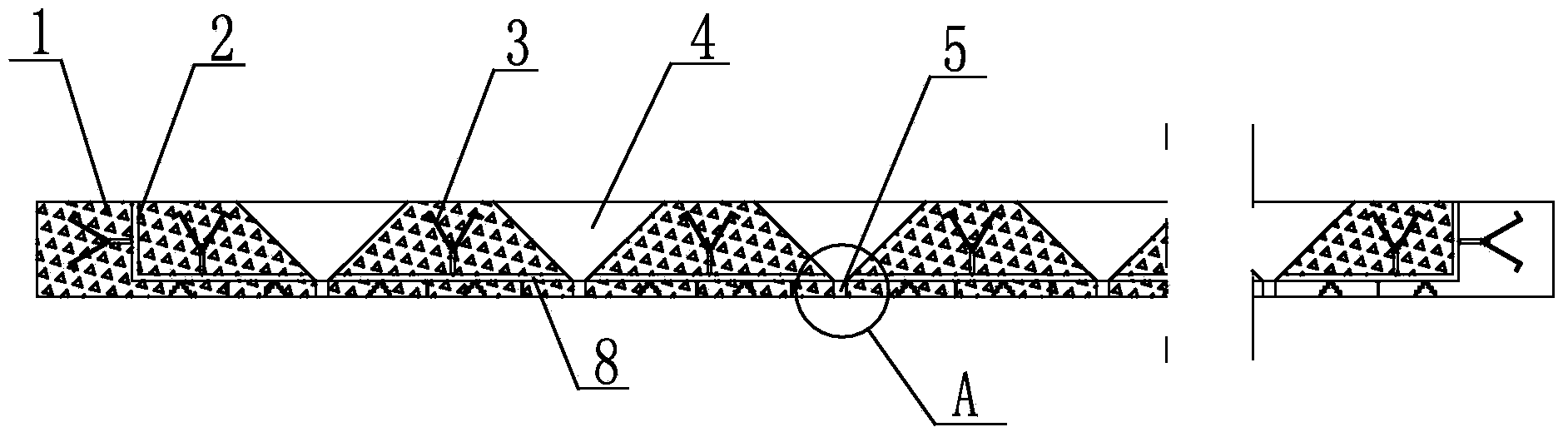

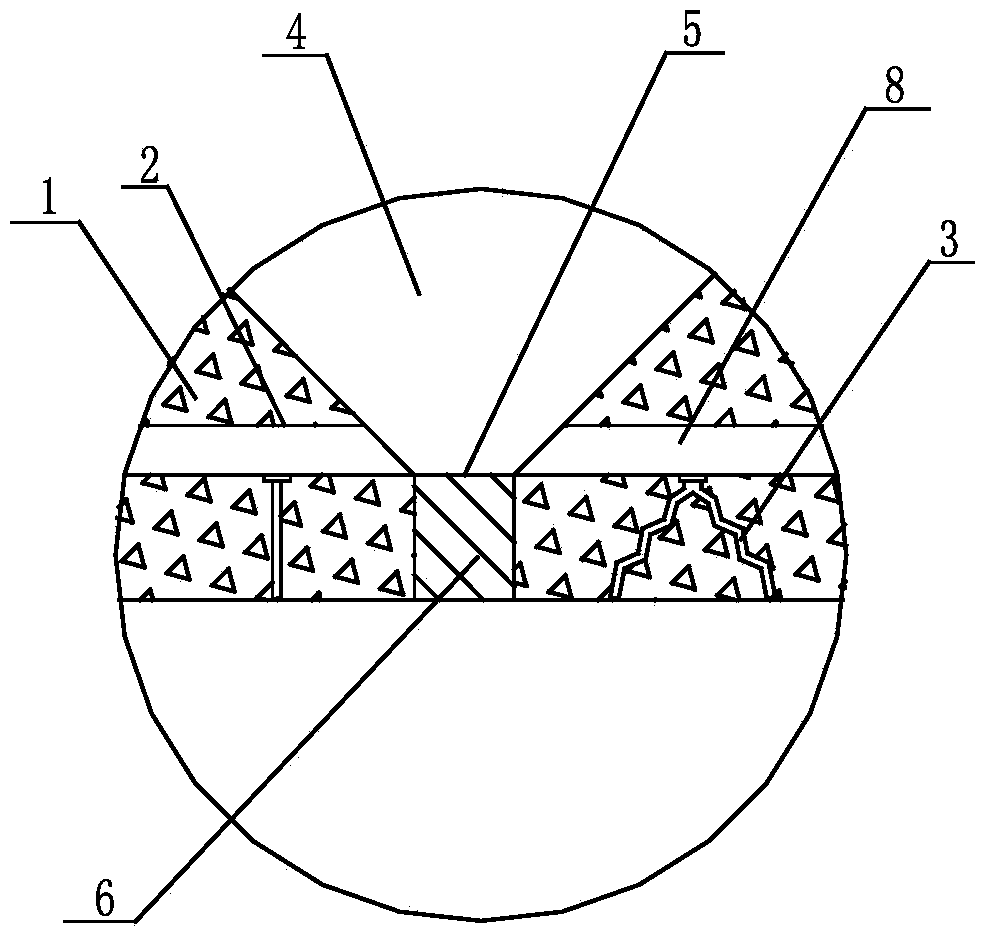

[0036] Figure 1~3The online slag removal device for a walking beam heating furnace shown includes a heat-resistant steel plate 2 with a rectangular box-shaped structure with an upper opening, and metal anchors 3 are arranged on the inner and outer walls of the heat-resistant steel plate 2, and the metal anchors 3 and The refractory castable is poured into one body; wherein, the refractory castable forms a plurality of funnel-shaped silos 4 in a row on the inner wall of the heat-resistant steel plate 2, and the refractory castable forms a high-temperature-resistant heat insulation layer 1 on the outer wall of the heat-resistant steel plate 2; The silo 4 is filled with a slagging agent, and the bottom of the silo 4 is provided with an outlet 5 for discharging the slag agent, and the outlet 5 is provided with an outlet that can be melted at the working temperature of the second heating section of the heating furnace. Material stuffing6.

[0037] The heat-resistant steel plate 2...

Embodiment 2

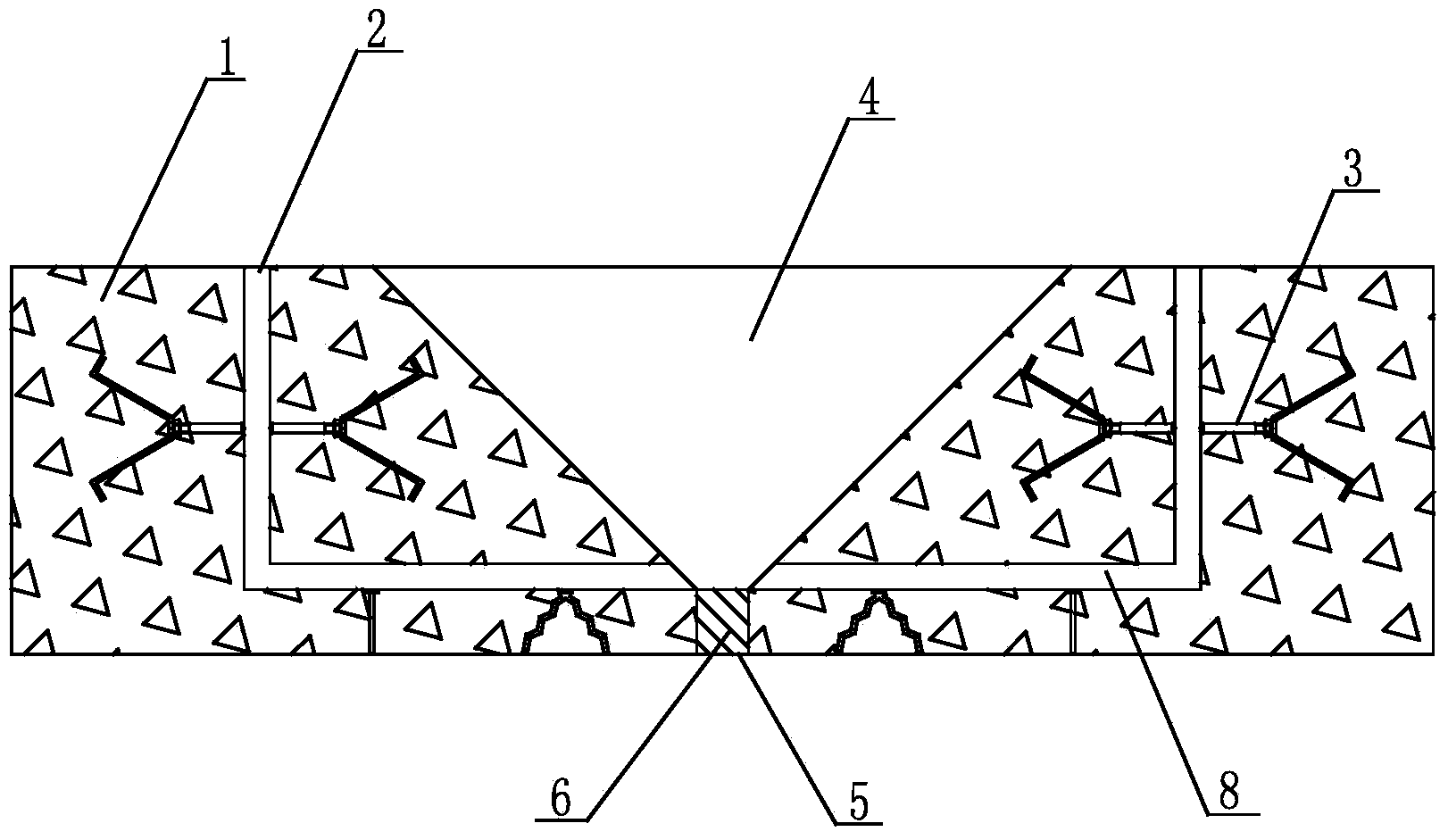

[0039] Figure 4~6 The online slag removal device for a walking beam heating furnace shown includes a heat-resistant steel plate 2 with a rectangular box-shaped structure with an upper opening, and metal anchors 3 are arranged on the inner and outer walls of the heat-resistant steel plate 2, and the metal anchors 3 and The refractory castable is poured into one body; wherein, the refractory castable forms a plurality of funnel-shaped silos 4 in a row on the inner wall of the heat-resistant steel plate 2, and the refractory castable forms a high-temperature-resistant heat insulation layer 1 on the outer wall of the heat-resistant steel plate 2; The silo 4 is filled with a slagging agent, and the bottom of the silo 4 is provided with an outlet 5 for discharging the slag agent, and the outlet 5 is provided with an outlet that can be melted at the working temperature of the second heating section of the heating furnace. Material stuffing6.

[0040] The heat-resistant steel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com