Efficient methane production device

A biogas and high-efficiency technology, applied in the fields of gas production bioreactor, biological sludge treatment, waste fuel, etc., can solve problems such as adverse effects and waste of biogas development and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the examples. It should be understood that the examples are only used to illustrate the present invention but not to limit the protection scope of the present invention. In addition, it should be understood that after reading the content taught by the present invention, changes or modifications made to the present invention by those skilled in the art in various equivalent forms also fall within the scope required by the claims of the present application.

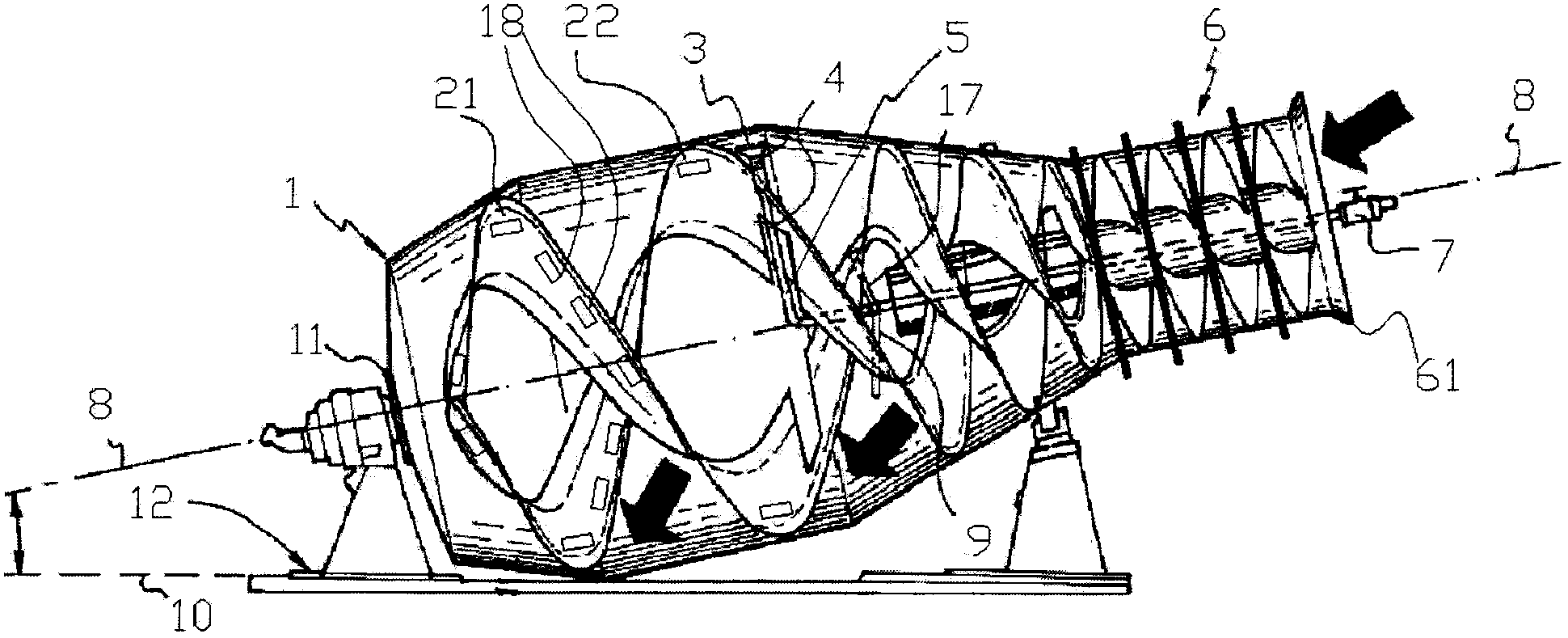

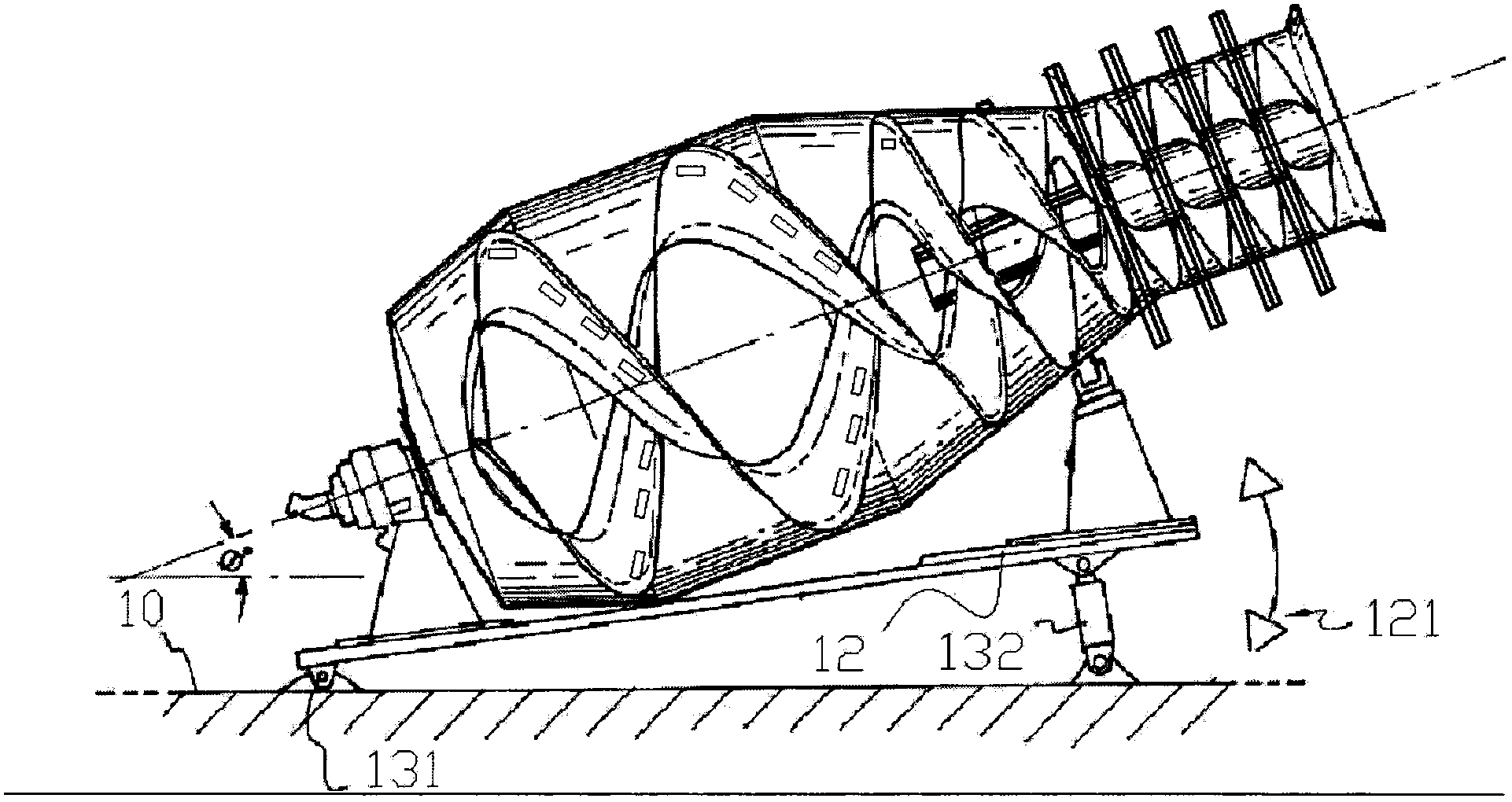

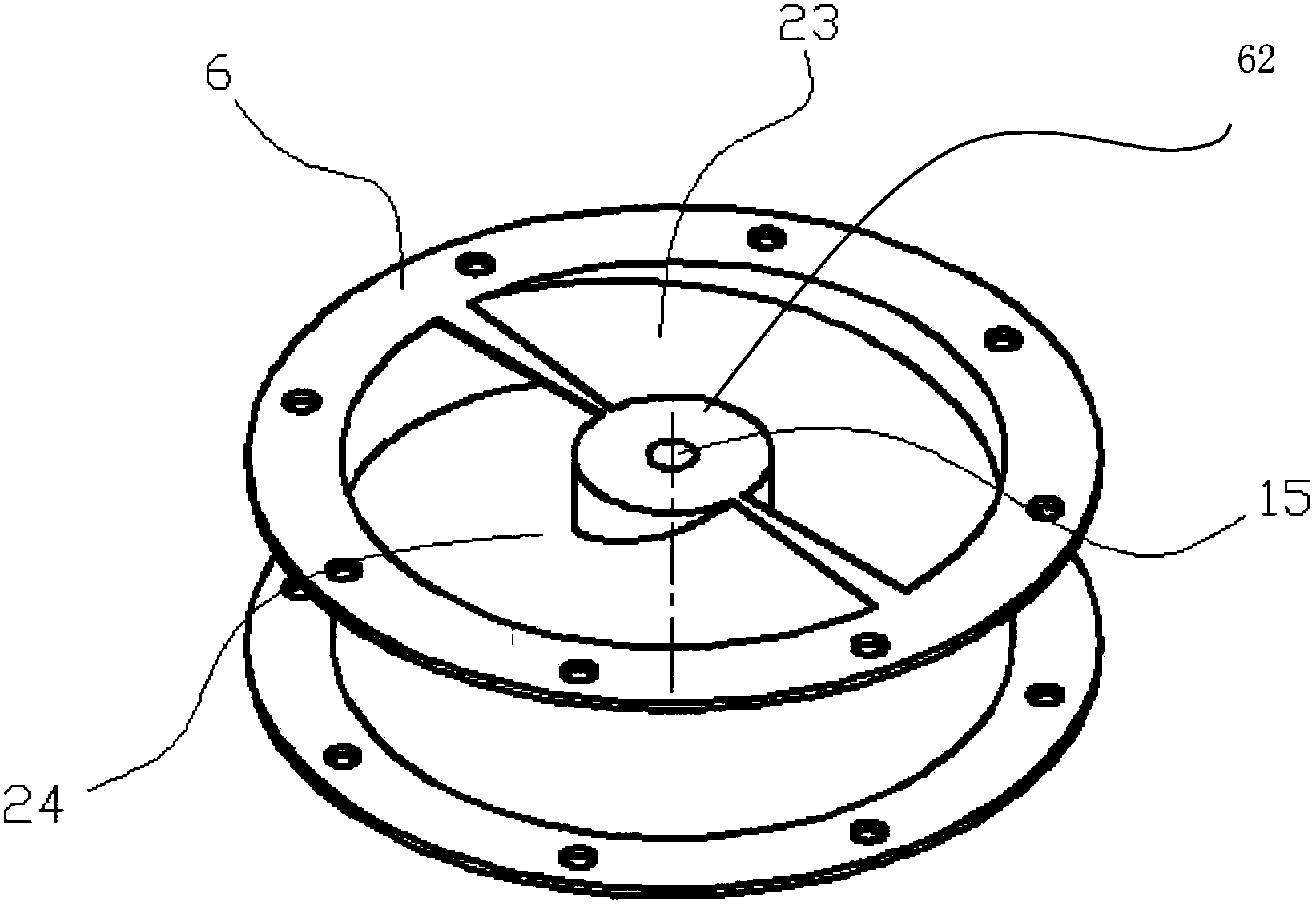

[0035] Such as Figure 1 to Figure 3 The shown high-efficiency biogas production device includes a rotatable spindle-shaped biogas forming container 1 driven by a drive motor. The rotating structure does not belong to the protection scope of this patent, so it is not described in detail. Two helical blades 21 and 22 are fixed inside the forming container 1 . The helical blades 21 , 22 extend along the inner shape of the biogas forming conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com