Polyvinylidene fluoride/graphene composite material and preparation method thereof

A technology of polyvinylidene fluoride and composite materials, which is applied in the field of graphene, can solve the problems of technology promotion and industrial application, complex preparation methods, high cost, etc., achieve improved thermal conductivity and electrical conductivity, simple preparation process, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

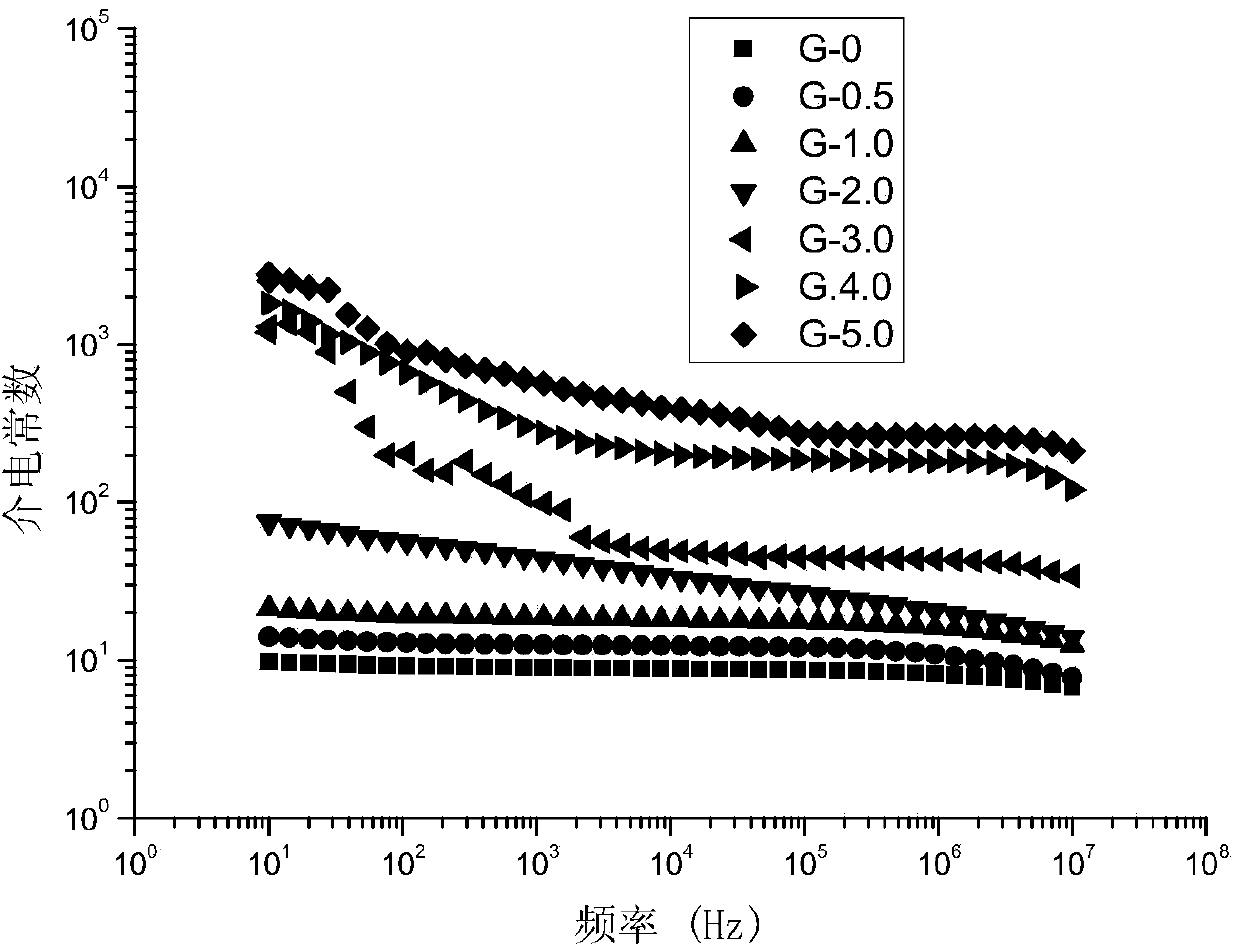

Examples

Embodiment 1

[0032] Add 91g of polyvinylidene fluoride, 3g of graphene, 5g of stearic acid amide, 0.5g of white oil, 0.3g of sodium lauryl sulfate, and 0.2g of silane coupling agent KH560 into a high-speed mixer and mix for 5 minutes. Mix well After that, a mixture is obtained. The mixture was melted and hot-pressed for 10 minutes at 200° C. and 10 MPa pressure with a flat vulcanizer to obtain a polyvinylidene fluoride / graphene composite material.

Embodiment 2

[0034] Add 87.4g of polyvinylidene fluoride, 5g of graphene, 3g of stearic acid amide, 3g of ethylene bisstearamide, 1g of white oil, 0.4g of sodium lauryl sulfate, and 0.2g of silane coupling agent KH560 into the high-speed mixing Mix in the machine for 5 minutes, and mix well to obtain the mixture. The mixture was melted and hot-pressed for 10 minutes at 200° C. and 10 MPa pressure with a flat vulcanizer to obtain a polyvinylidene fluoride / graphene composite material. Tested by a four-probe tester, the average volume resistivity is 6.767 .

Embodiment 3

[0036] Add 81.4g of polyvinylidene fluoride, 10g of graphene, 4g of stearic acid amide, 2g of ethylene bisstearamide, 2g of white oil, and 0.6g of sodium lauryl sulfate into a high-speed mixer and mix for 8 minutes. Mix well After that, a mixture is obtained. The mixture was hot-pressed for 10 minutes at 200° C. and 10 MPa pigment with a flat vulcanizer to obtain a polyvinylidene fluoride / graphene composite material. The thermal diffusivity measured at 30°C is 0.676 , the specific heat capacity is 1.053 , the thermal conductivity is 1.008 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com