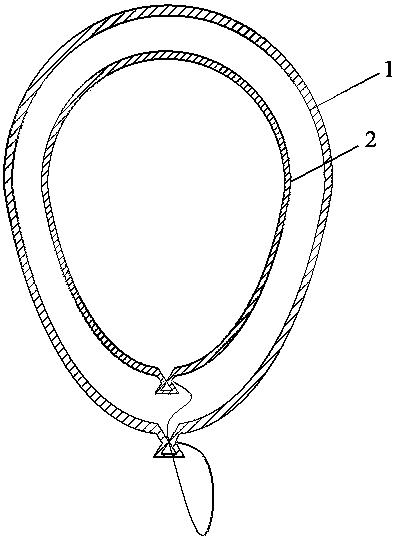

Weather balloon as well as preparation method thereof and combined balloon containing weather balloon

A weather balloon and combined technology, applied in the field of meteorological detection, can solve the problems of insufficient efficiency, inability to meet the requirements of highly efficient use, lack of high-altitude data at stations, etc., and achieve the effect of improving the elongation rate and resilience performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides the preparation method of weather balloon of the present invention, and this method comprises the steps:

[0057] S1, sulfur, N-phenyl-2-naphthylamine, N-phenyl-N'-isopropyl-p-phenylenediamine, ethyl-phenyl-zinc dithiocarbamate and zinc oxide are made into water Dispersions;

[0058] S2, Potassium hydroxide, casein and flat plus O are prepared into a solution;

[0059] S3, preparing machine oil and emulsified paraffin into emulsion;

[0060] S4, adding the water dispersion and the solution to the concentrated natural rubber latex, then adding the emulsion, mixing and stirring evenly to obtain the composition;

[0061] S5. Prepare the composition to obtain a weather balloon.

[0062] Preferably, the method also includes adding neoprene latex into the composition before step S5.

[0063] The concrete steps of step S5 are:

[0064] 1. Dip impregnation: Dip the balloon mold in coagulant;

[0065] 2. Film: Soak the mold with coagulan...

Embodiment 1

[0071] 1. Composition of weather balloons

[0072] 100 parts of centrifugally concentrated natural latex, 0.15 parts of potassium hydroxide, 0.2 parts of casein, 0.1 parts of Pingpingjia O (dodecyl polyoxyethylene ether), 1 part of sulfur, antioxidant D (N-phenyl-2-naphthalene Amine) 1.5 parts, PX (ethyl-phenyl-zinc dithiocarbamate) 1 part, 4010NA (N-phenyl-N'-isopropyl-p-phenylenediamine) 2 parts, zinc oxide 1.5 parts, The weight ratio of machine oil is 3.00 parts, and emulsified paraffin is 5 parts;

[0073] 2. Preparation method

[0074] (1) Prepare the composition

[0075] S1, sulfur, antioxidant D, 4010NA, PX and zinc oxide are made into water dispersion;

[0076] S2, Potassium hydroxide, casein and flat plus O are prepared into a solution;

[0077] S3, preparing machine oil and emulsified paraffin into emulsion;

[0078] S4, adding the water dispersion and the solution to the concentrated natural rubber latex, then adding the emulsion, mixing and stirring evenly to ...

Embodiment 2

[0087] 1. Composition of weather balloons

[0088] 100 parts of centrifugally concentrated natural latex, 0.30 parts of potassium hydroxide, 0.1 part of casein, 0.15 parts of Pingpingjia O (dodecyl polyoxyethylene ether), 2 parts of sulfur, antioxidant D (N-phenyl-2-naphthalene Amine) 1 part, PX (ethyl-phenyl-zinc dithiocarbamate) 1.5 parts, 4010NA (N-phenyl-N'-isopropyl-p-phenylenediamine) 1 part, zinc oxide 3 parts, The weight ratio of mechanical oil is 5.0 parts, neoprene latex is 5 parts, and emulsified paraffin is 7 parts;

[0089] 2. Preparation method

[0090] (1) Prepare the composition

[0091] S1, sulfur, antioxidant D, 4010NA, PX and zinc oxide are made into water dispersion;

[0092] S2, Potassium hydroxide, casein and flat plus O are prepared into a solution;

[0093] S3, preparing machine oil and emulsified paraffin into emulsion;

[0094] S4. Add the water dispersion and the solution to the concentrated natural rubber latex, then add the emulsion and neopre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com