Organic pollution resistance ion exchange resin, and preparation method and application of resin

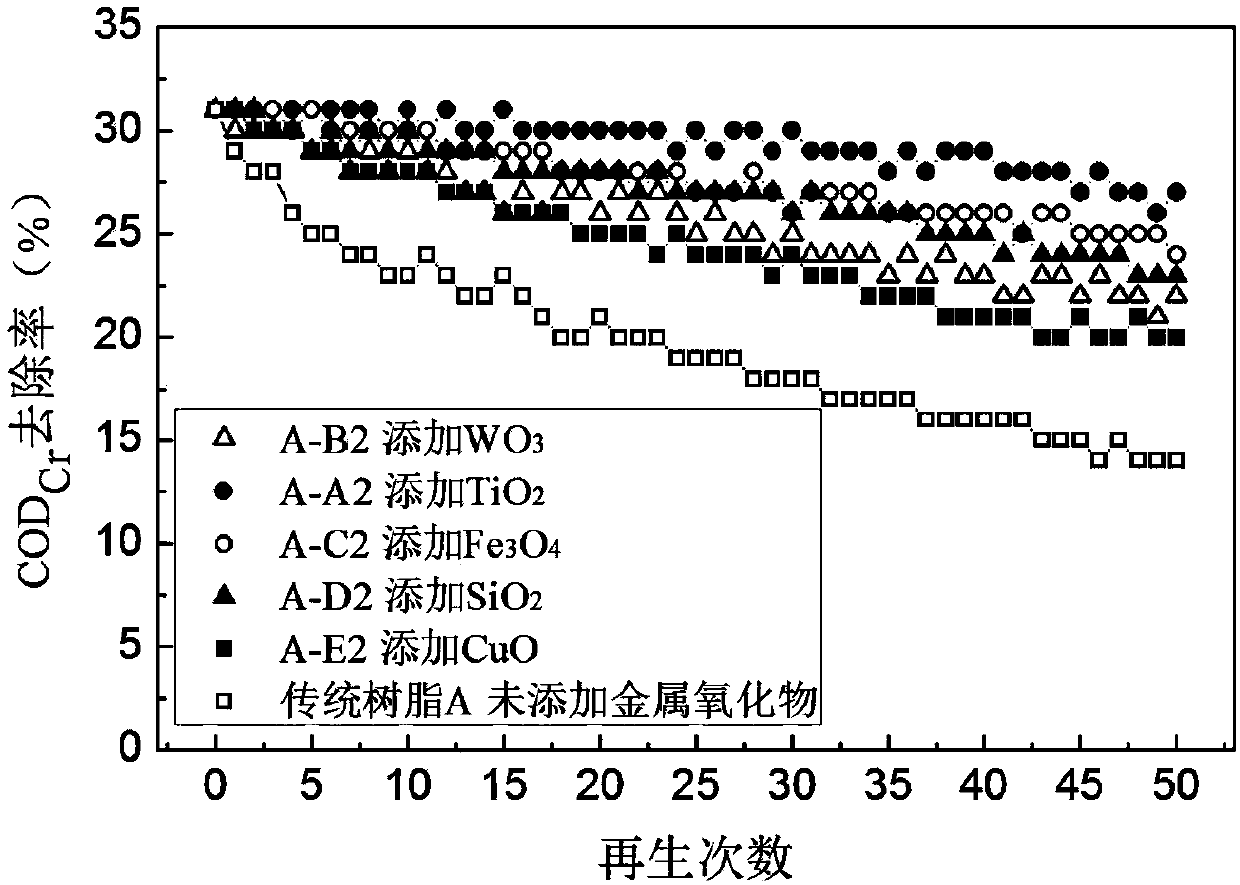

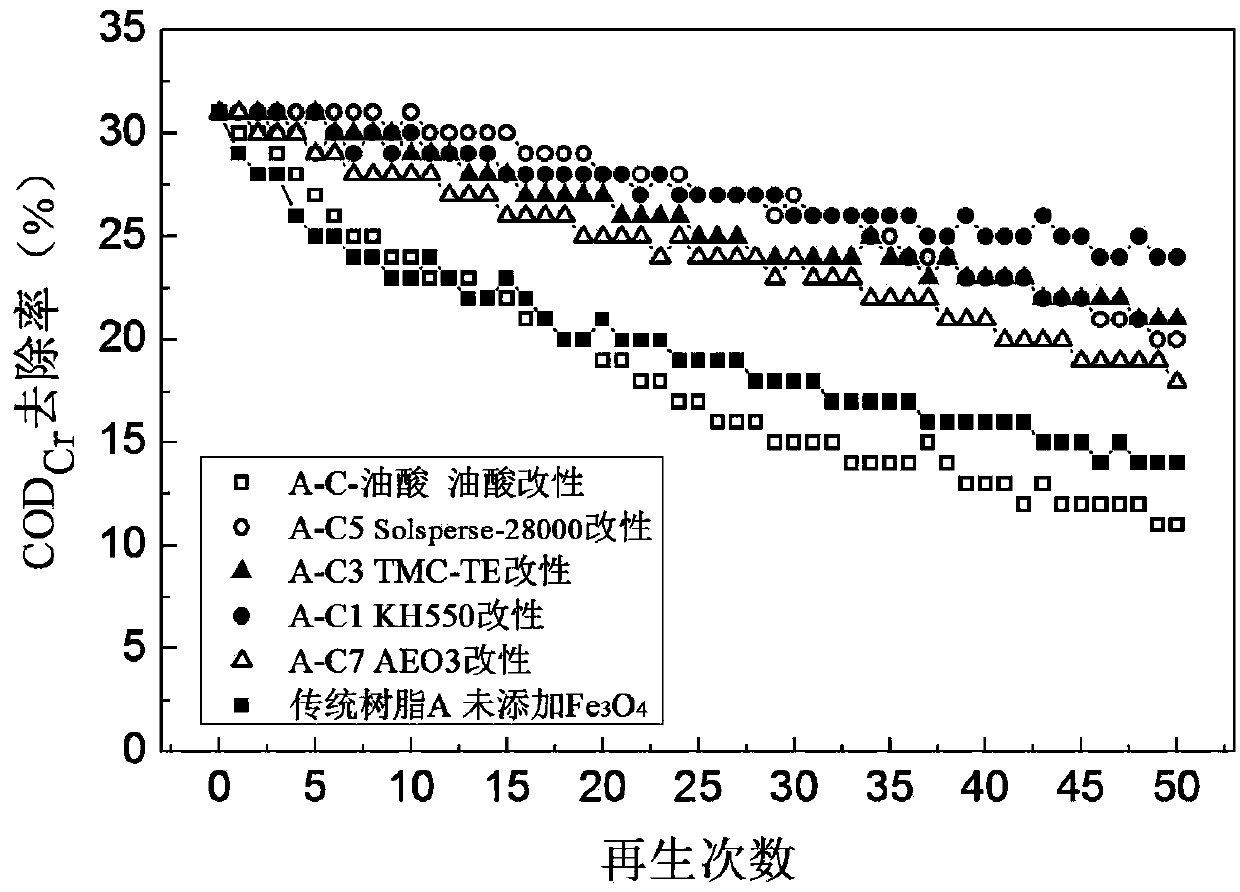

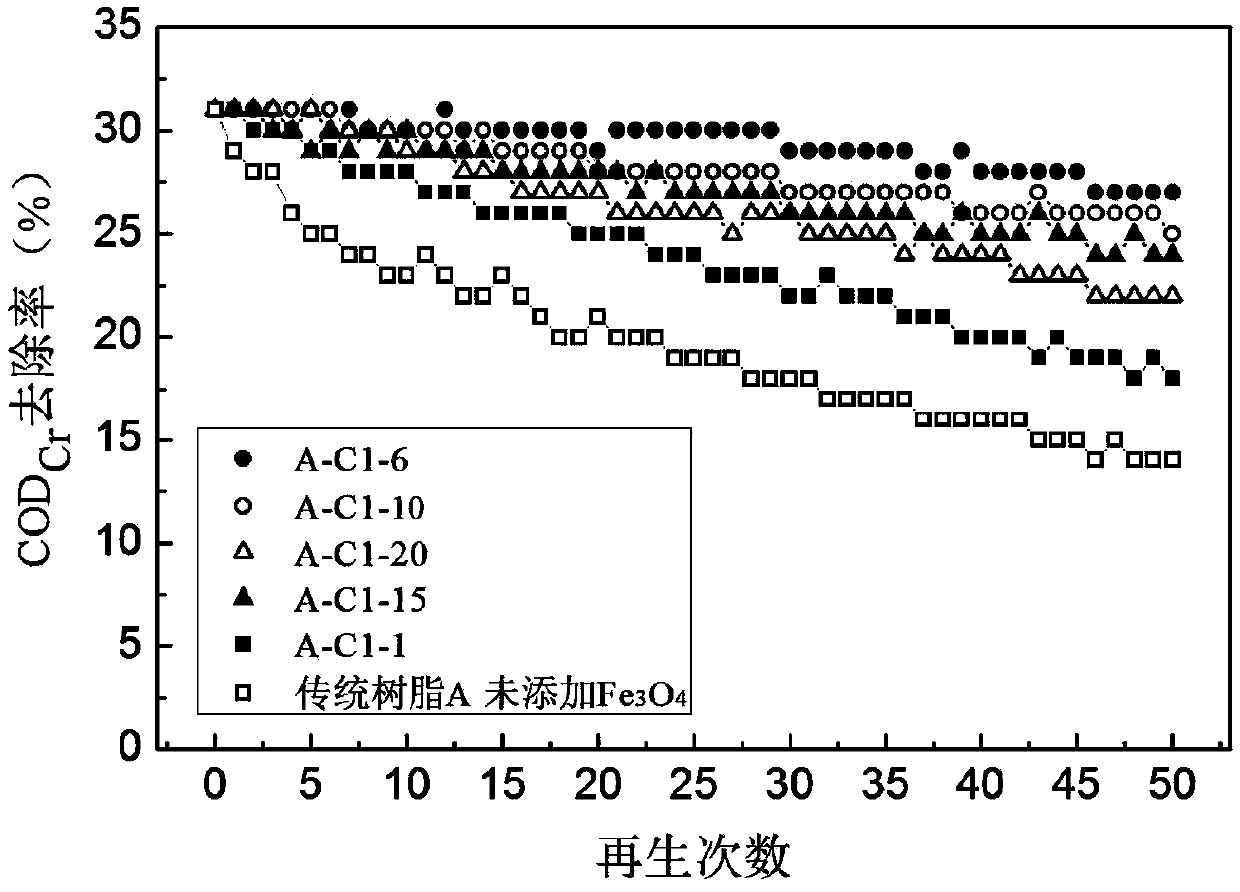

A technology of ion exchange resin and polluting ions, which is applied in ion exchange, cation exchange, anion exchange, etc. It can solve the problems of short service life and low removal rate, and achieve the effects of not easily polluting the resin, improving resin pores, and facilitating the entry and exit of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing an anti-organic pollution ion exchange resin, characterized in that the preparation steps of adding the ion exchange resin are:

[0051] (1) Preparation of the oil phase: The oil phase contains monomers, crosslinking agents, and initiators, the weight ratio of the monomers to the crosslinking agents is 1:0.02-0.45, and the weight ratio of the monomers to the initiators is 1 : 0.003~0.15; The monomer of the present invention belongs to the monomer that the oil phase in the resin prepared by prior art personnel often adopts, and cross-linking agent and initiator are also common materials of those skilled in the art, so the present invention no longer one by one describe. In this embodiment, methyl acrylate is used as the monomer, and the weight ratio of the monomer to the crosslinking agent is 1:0.35, and divinylbenzene is used as the crosslinking agent in this embodiment. The weight ratio of the monomer to the initiator is 1:0.10, and the initiato...

Embodiment 2

[0075] A method for preparing an anti-organic pollution ion-exchange resin, characterized in that the preparation steps of adding the ion-exchange resin are the same as in Example 1, the difference being:

[0076] (1) Preparation of oil phase: the weight ratio of monomer to crosslinking agent is 1:0.02, and the weight ratio of monomer to initiator is 1:0.003;

[0077] (2) Preparation of the water phase: add a dispersant accounting for 3% of the mass ratio of the water phase to the water phase; the ratio of the total mass of the water phase to the total mass of the oil phase is 1:0.8; where the dispersant refers to a mass ratio of 1: 1 mixture of polyvinyl alcohol and silicate.

[0078] (3) Modification of inorganic particles: Stir at 250rpm for 4h at 20°C; add modifier and continue stirring for 0.5h; finally, dry; the mass ratio of inorganic particles to methanol solution is 1:10; the modification The mass ratio of neutralizing agent to inorganic particles is 1:5.

[0079] (...

Embodiment 3

[0088] A method for preparing an anti-organic pollution ion-exchange resin, characterized in that the preparation steps of adding the ion-exchange resin are the same as in Example 1, the difference being:

[0089] (1) Preparation of oil phase: the weight ratio of monomer to crosslinking agent is 1:0.45, and the weight ratio of monomer to initiator is 1:0.15.

[0090] (2) Preparation of the water phase: add 0.2% dispersant to the water phase; the ratio of the total mass of the water phase to the total mass of the oil phase is 1:0.4; where the dispersant refers to a mass ratio of 1: 1 mixture of polyvinyl alcohol and silicate.

[0091] (3) Modification of inorganic particles: Stir at 250rpm for 4h at 20°C; add modifier and continue stirring for 0.5h; finally, dry; the mass ratio of inorganic particles to methanol solution is 1:3-10; The mass ratio of modifier to inorganic particles is 1:0.05-5.

[0092] (4) Addition of inorganic particles after modification: In the water phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com