Laser packaging method and equipment

A laser packaging and equipment technology, applied in glass manufacturing equipment, glass remolding, glass molding and other directions, can solve problems such as low packaging efficiency, and achieve the effect of improving packaging efficiency and reducing alignment accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

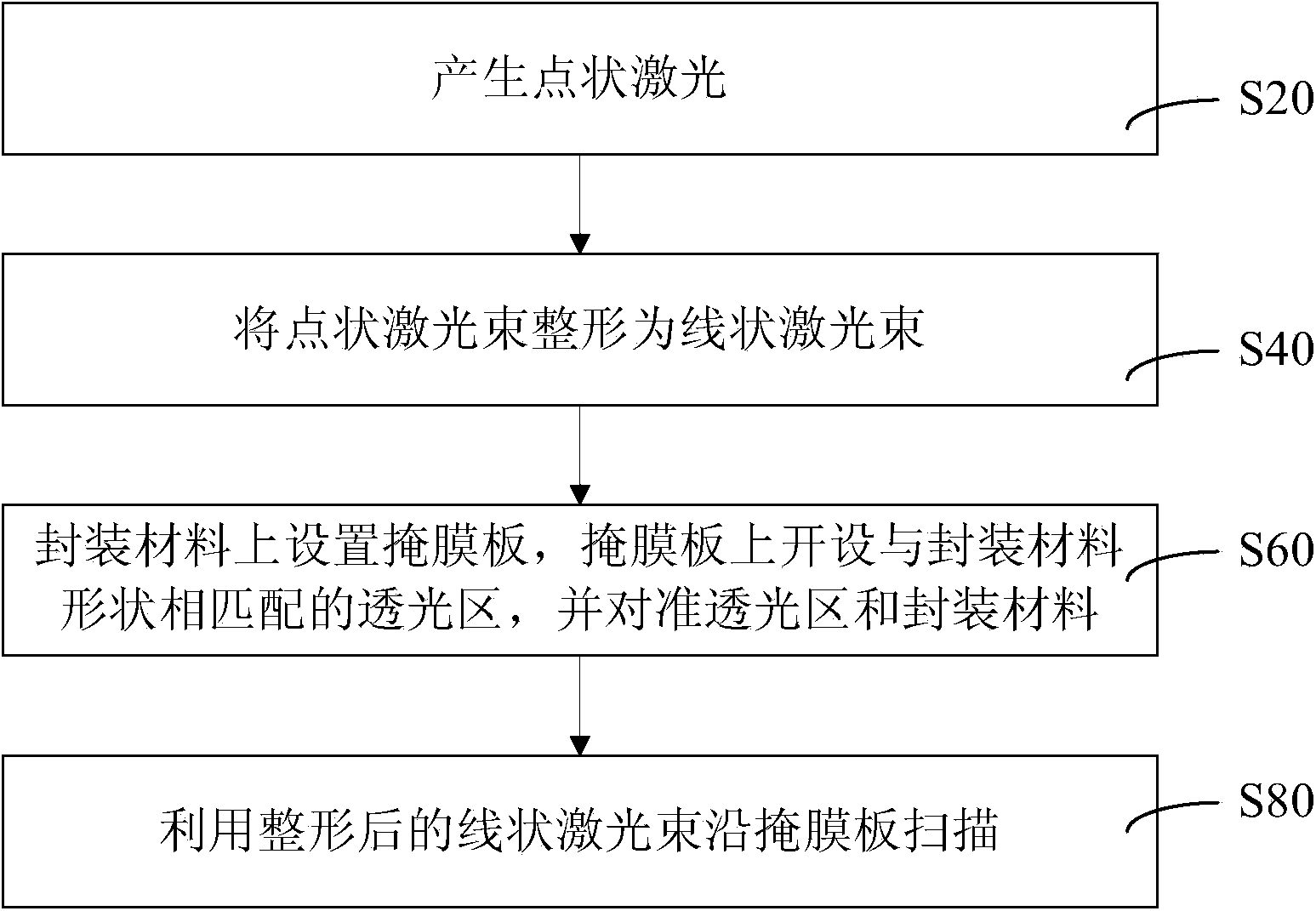

[0027] The present invention proposes a laser packaging method, refer to Figure 1 to Figure 7 , the method includes the following steps:

[0028] Step S20, generating a point laser beam.

[0029] Specifically, a point-shaped laser beam is a laser beam whose irradiation area is a small spot or a spot.

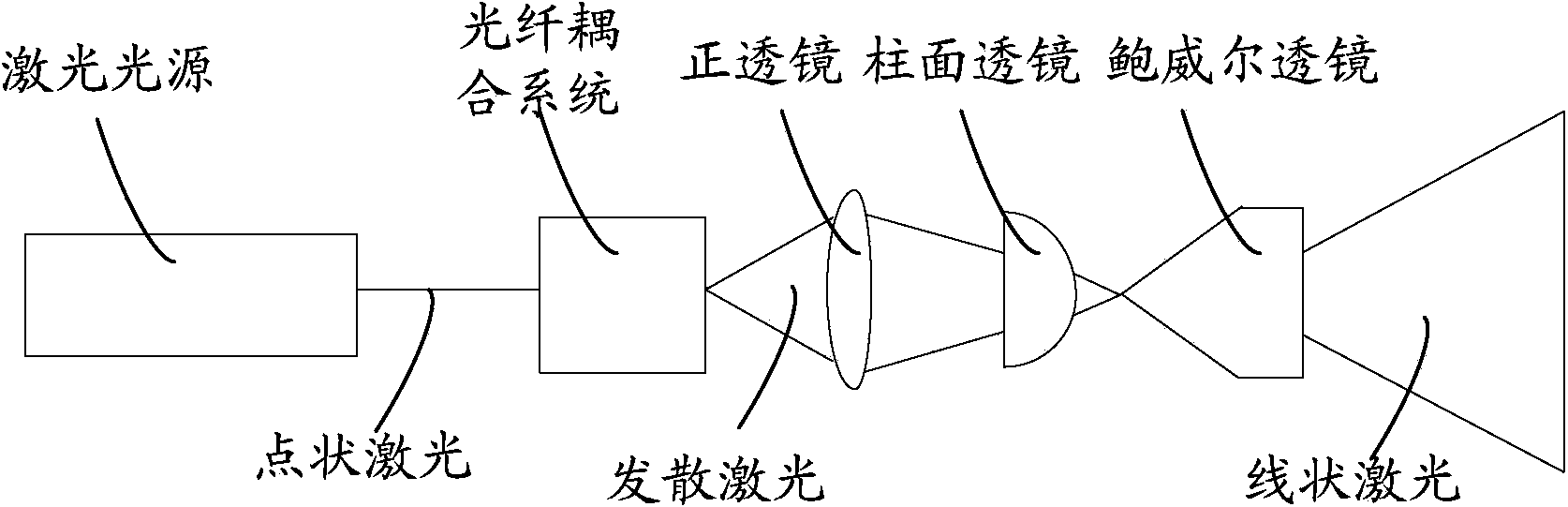

[0030] Step S40, shaping the point-shaped laser beam into a linear laser beam.

[0031] Specifically, the line-shaped laser beam is a laser beam whose irradiation area is a straight line, and can be obtained by passing the point-shaped laser beam through a lens group or using a grating diffraction method.

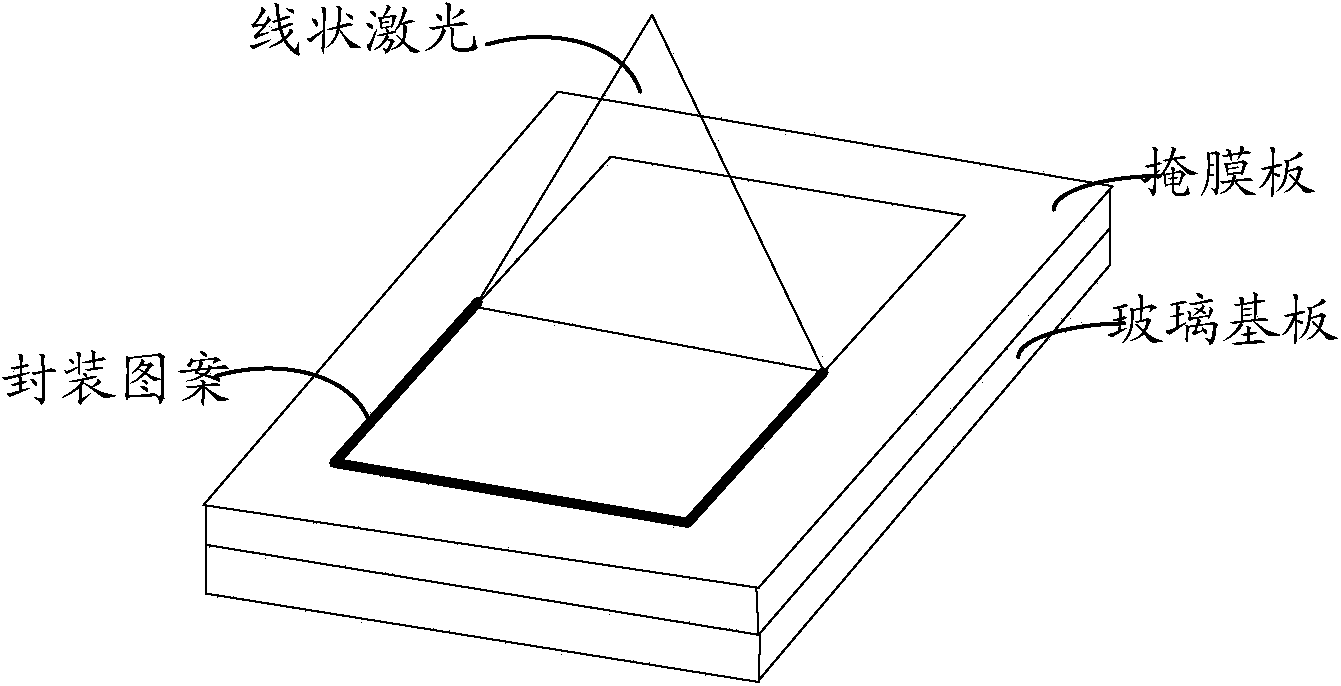

[0032] In step S60, a mask is set on the packaging material, a light-transmitting area matching the shape of the packaging material is opened on the mask, and the light-transmitting area and the packaging material are aligned.

[0033] Specifically, the encapsulation material is provided on the glass substrate. The mask plate is provided with a light-transmitting area, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com