Fracturing flowback fluid treatment method

A technology of fracturing flowback fluid and treatment method, which is applied in the treatment of fracturing flowback fluid and the field of fracturing flowback fluid treatment, and can solve the problem of difficult water quality reaching the national first-level discharge standard, unsatisfactory treatment effect, and process steps cumbersome and other problems, to achieve the effect of ideal treatment effect, good pollutant removal effect and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

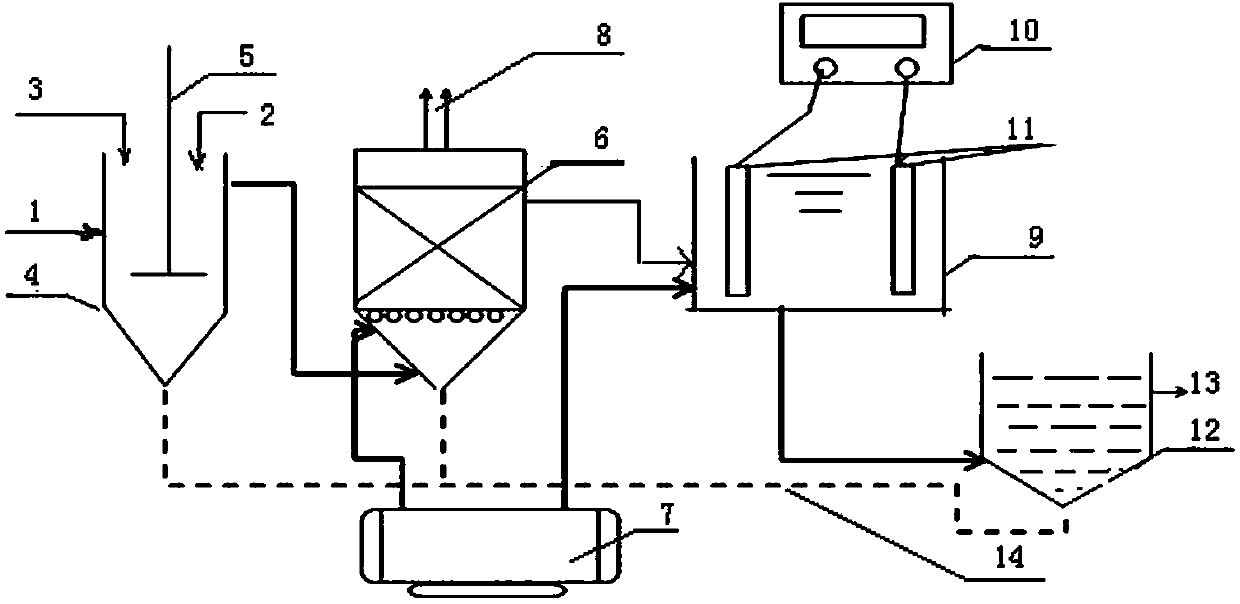

Method used

Image

Examples

Embodiment 1

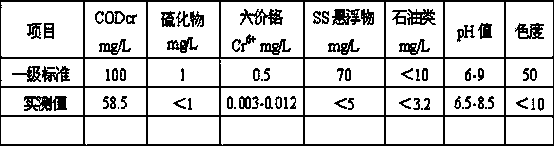

[0039] ①. Gel breaking and flocculation: first add SF--Ⅲ compound flocculation dosage of 1.0g / L to the fracturing flowback fluid as a pretreatment agent, then add a gel breaking agent of 1.5g / L, and then add a regulator The amount is 0.5ml / L, the residence and sedimentation time is 3 hours, and the supernatant is discharged into the catalytic oxidation facility for treatment. And timely detect the water quality indicators of the facility's inflow and outflow.

[0040] Among them, the water quality of facility influent (fracturing flowback fluid): CODcr 7553mg / L; PH value 9.1; appearance is light yellow viscous liquid; has pungent smell.

[0041]The effluent water quality after gel breaking and flocculation: CODcr 1259mg / L; removal rate up to 83.2%; PH value 8.5; colorless liquid.

[0042] ②. Catalytic oxidation: Add 0.5ml / L concentrated sulfuric acid with a concentration of 98% to the coagulation effluent, adjust the pH value to 3, enter the catalytic oxidation facility, and ...

Embodiment 2

[0048] ①. Gel breaking and flocculation: first add SF--Ⅲ compound flocculation dosage of 0.8g / L to the fracturing flowback fluid as a pretreatment agent, then add a gel breaking agent of 1.6g / L, and then add a regulator The amount of the solution is 0.4ml / L, the residence and sedimentation time is 3.5 hours, and the supernatant is discharged into the catalytic oxidation facility for treatment. And timely detect the water quality indicators of the facility's inflow and outflow.

[0049] Among them, the water quality of facility influent (fracturing flowback fluid): CODcr 6530mg / L; PH value 9.3; appearance is light yellow viscous liquid; has pungent smell.

[0050] The effluent water quality after gel breaking and flocculation: CODcr 1227.6mg / L; removal rate up to 81.2%; PH value 8.8; colorless liquid.

[0051] ②. Catalytic oxidation: add 0.7ml / L concentrated sulfuric acid with a concentration of 98% to the coagulation effluent, adjust the pH value to 3.3, enter the catalytic o...

Embodiment 3

[0057] ①. Gel breaking and flocculation: first add SF-Ⅲ composite flocculation dosage of 0.8g / L to the fracturing flowback fluid as a pretreatment agent, then add a gel breaking agent of 1.3g / L, and then add a regulator The amount of the solution is 0.7ml / L, the residence and sedimentation time is 2.5 hours, and the supernatant is discharged into the catalytic oxidation facility for treatment. And timely detect the water quality indicators of the facility's inflow and outflow.

[0058] Among them, the water quality of the facility influent (fracturing flowback fluid): CODcr 6409mg / L; PH value 9.5; the appearance is a light yellow viscous liquid; it has a pungent smell.

[0059] The water quality of the effluent after gel breaking and flocculation: CODcr 1190mg / L; the removal rate is 81.4%; the pH value is 8.0; it is a colorless liquid.

[0060] ②. Catalytic oxidation: Add 0.6ml / L concentrated sulfuric acid with a concentration of 98% to the coagulation effluent, adjust the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com