Diatomite reactor device

A diatom concentrate and reactor technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of insufficient heavy metal microbial substances, no sludge reuse, difficult urban sewage treatment, etc., to achieve convenient Daily operation and maintenance, saving construction investment costs, efficient mud-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

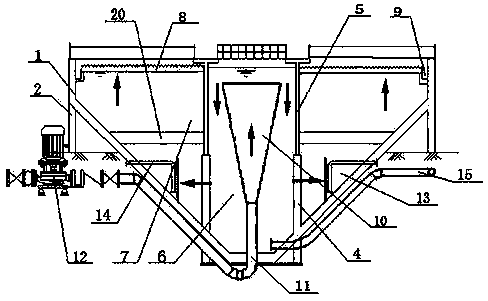

[0027] The present invention has been successfully applied in Shanxi Shanxi Coal Group Sewage Treatment Plant. The effluent water quality of this project has reached GB18918-2002 Grade A Standard, and the daily processing capacity is 12,000 cubic meters. Now this is an embodiment of the present invention.

[0028] A diatom concentrate reactor equipment. The shell 1 of the equipment is connected by an upper octagonal cylinder and a lower octagonal pyramid. This part only needs technical transformation on the basis of the original sewage treatment, and does not need to occupy new land. The upper octagonal column is provided with eight support columns 2 at the eight corners, and the eight support columns 2 are connected by cross beams. Eight columns 4 are arranged on the slope of the lower octagonal body of the housing 1, and the columns 4 pass through the slope of the lower octagonal body and are fixed to the ground to support the flocculation chamber 6 and the entire casing. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com