Welding wire and welding flux for 9Ni low-temperature steel submerged arc welding as well as application of welding wire and welding flux

A technology for submerged arc welding and low-temperature steel, which is applied in the field of submerged arc welding wire and flux for low-temperature steel, submerged arc welding wire and flux for 9Ni low-temperature steel, and can solve the problems of poor weld formation, weld metal strength and low-temperature toughness To meet the actual needs, the quality of welded joints is not good enough, etc., to achieve stable welding process, overcome horizontal butt welding, and good weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

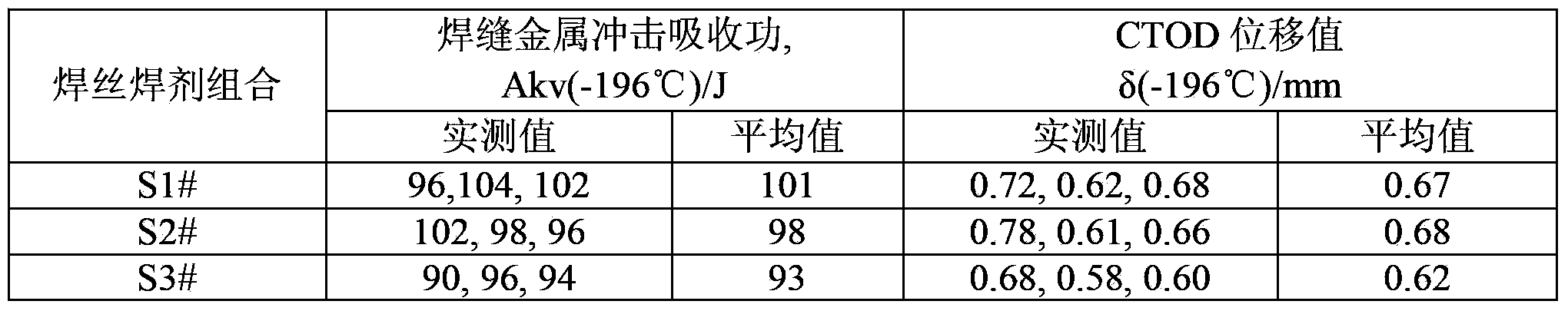

Embodiment 1

[0026] Example 1: Select welding wire flux combination S1#, the welding wire composition is C0.02%, Si0.05%, Mn0.08%, Mo22%, W2.5%, Al0.12%, the balance is Ni and inevitable impurities ; Flux composition: Ti 2 O 3 15%, MgO27%, CaF 2 28%, Al 2 O 3 16%, and the remainder Na 2 O, the alkalinity is 4.0; the welding current is 180A, the welding voltage is 27V, the welding speed is 23cm / min, the interlayer temperature is less than or equal to 100℃, and the vertical submerged arc welding is carried out;

Embodiment 2

[0027] Embodiment 2: Select welding wire flux combination S2#, the welding wire composition is: C0.03%, Si0.08%, Mn0.05%, Mo18%, W3%, Al0.14%, the balance is Ni and inevitable impurities; Flux composition: Ti 2 O 3 12%, MgO24%, CaF 2 22%, Al 2 O 3 20%, the balance is Na 2 O, the alkalinity is 3.1; the welding current is 280A, the welding voltage is 34V, the welding speed is 34cm / min, and the interlayer temperature is less than or equal to 100℃, and the horizontal submerged arc welding is carried out;

Embodiment 3

[0028] Example 3: Select the welding wire flux combination S3#, the welding wire composition is: C0.015%, Si0.07%, Mn0.06%, Mo16%, W5.5%, Al0.18%, the balance is Ni and unavoidable Impurities; flux composition: Ti 2 O 3 15%, MgO18%, CaF 2 22%, Al 2 O 3 24%, the balance is Na 2 O, the alkalinity is 2.5; the welding current is 420A, the welding voltage is 37V, the welding speed is 40cm / min, and the interlayer temperature is less than or equal to 100℃, and the horizontal submerged arc welding is carried out;

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com