Thermal cracking carbon for removing polycyclic aromatic hydrocarbon in water as well as preparation method and application thereof

A polycyclic aromatic hydrocarbon, thermal cracking technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of farmland straw resource treatment not fundamentally solved, unreasonable utilization of straw, etc. Unreasonable utilization problem, water safety problem solving, effect of low desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

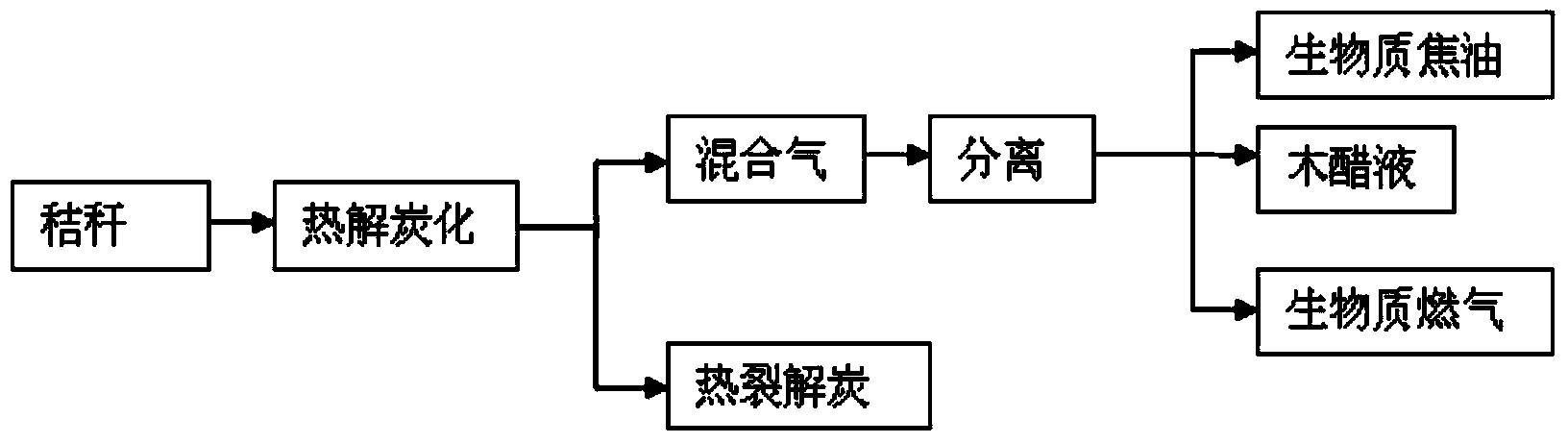

[0026] Wheat straw, corn straw and peanut shells are collected respectively, dried in the sun, and carbonized under the condition of anaerobic and 350-500 ℃ to make pyrolysis carbon. like figure 1 . The prepared pyrolysis carbon was dried to constant weight, crushed, passed through an 80-mesh sieve, and placed in a sealed bag for use.

Embodiment 2

[0028] A certain amount of different thermal pyrolysis carbon powders were weighed and added to the brown reagent bottle containing pyrene solution, and the adsorption amount was calculated by controlling pH, adsorption time and initial concentration. The effect of pH on the adsorption of pyrene by thermal pyrolysis carbon powder; the kinetic equation and adsorption rate of thermal pyrolysis carbon; the isotherm adsorption equation and maximum adsorption capacity of thermal pyrolysis carbon are obtained.

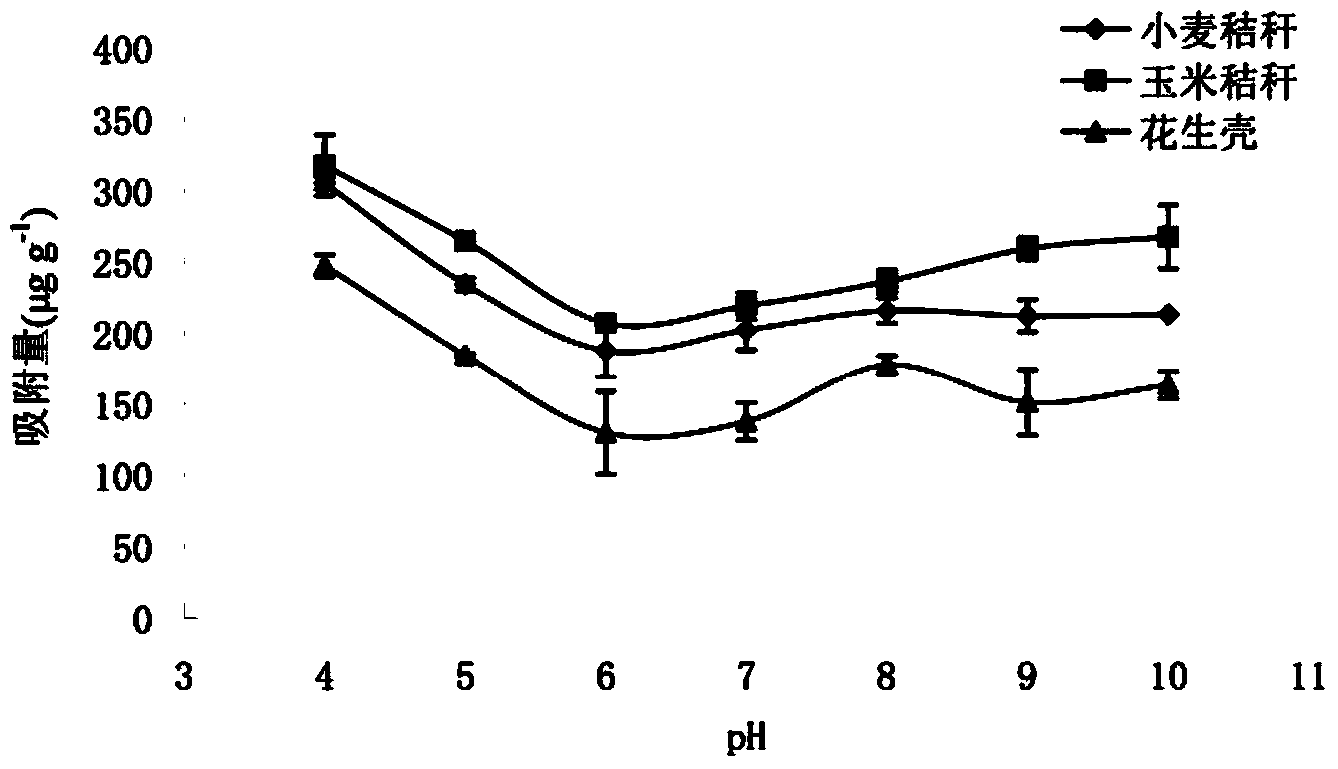

[0029] (1) Adsorption experiment of thermal pyrolysis carbon on polycyclic aromatic hydrocarbon pyrene

[0030] When the temperature is 25°C, take 5 mg of the dried thermal pyrolysis carbon powder (prepared in Example 1, the same below), respectively, and add them to 7 reagent bottles containing 40 ml of pyrene aqueous solution with a mass concentration of 60 μg / L. , adjust the pH to 4, 5, 6, 7, 8, 9 and 10, respectively. Vibration adsorption was carried out for 24h, and th...

Embodiment 3

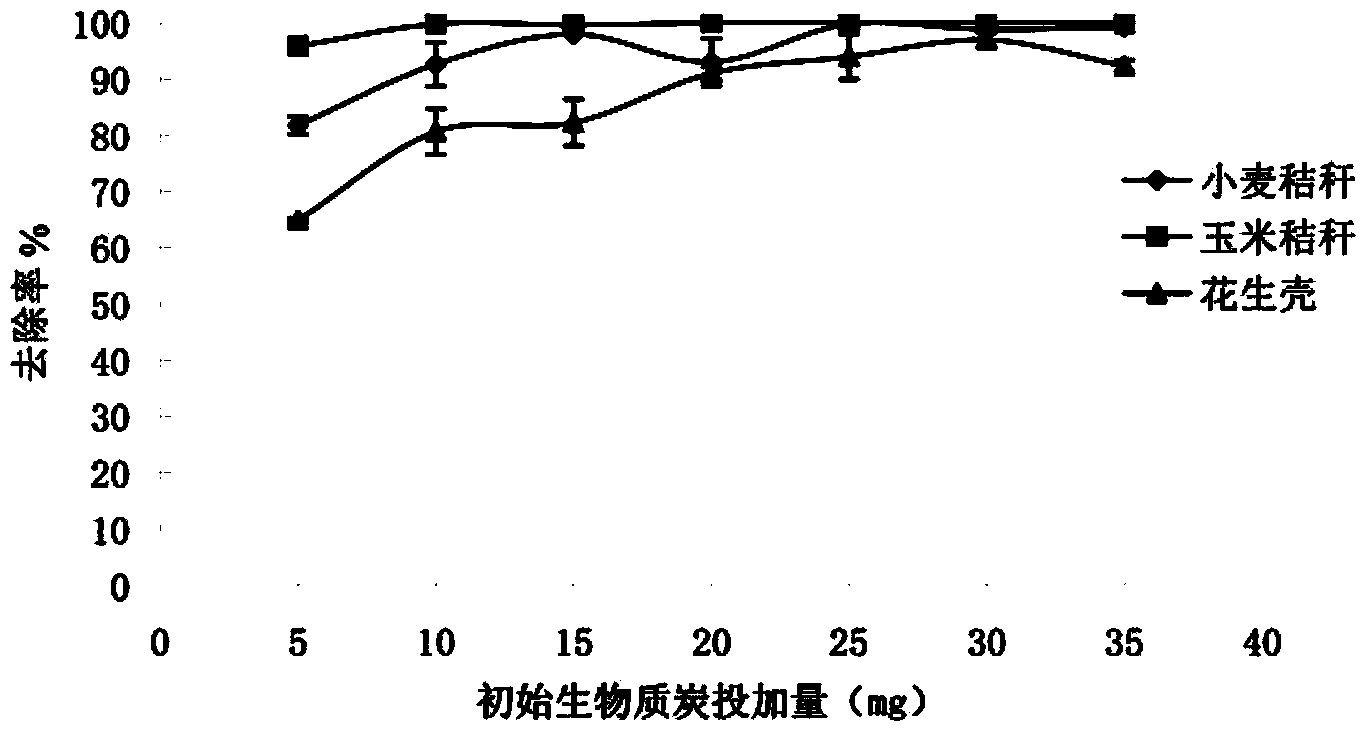

[0038] Weigh 15 mg of the three thermal pyrolysis carbon powders prepared in Example 1 and add them to a brown reagent bottle containing a 60 μg / L pyrene solution, respectively. The pH of the solution was controlled to be 4, and the solution was shaken and adsorbed for 24 hours at 25 °C. The solution was taken through a microporous membrane, and the filtrate was used to measure the concentration of pyrene in the aqueous phase by high performance liquid chromatography. The removal rate was calculated according to the initial concentration and the concentration after adsorption. The result is as Figure 7 , it was found that the average removal rate of pyrene was 98% for the pyrolytic carbon prepared from corn straw, 92% for the pyrolytic carbon prepared from wheat straw, and 92% for the pyrolytic carbon prepared from peanut shells. The removal rate was 82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com