Device and method for removing sulfur dioxide in waste gas

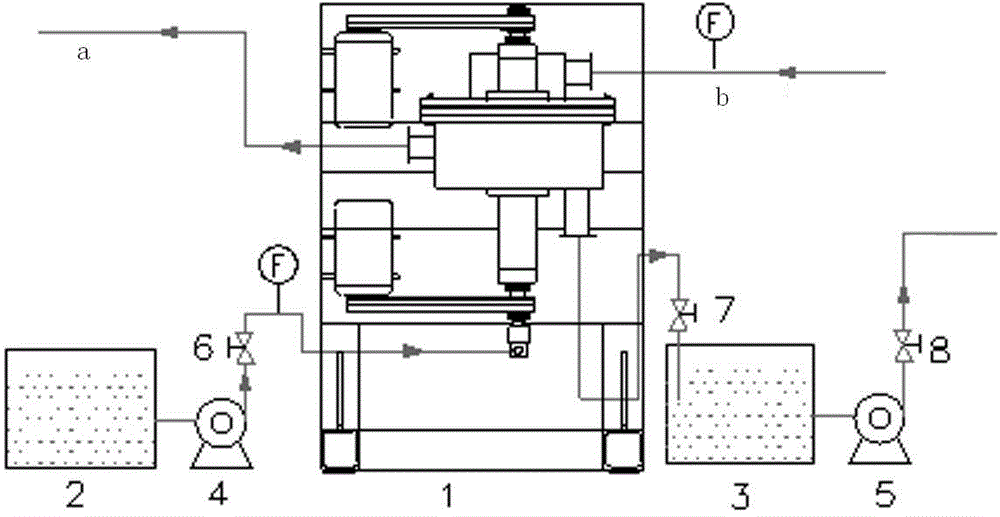

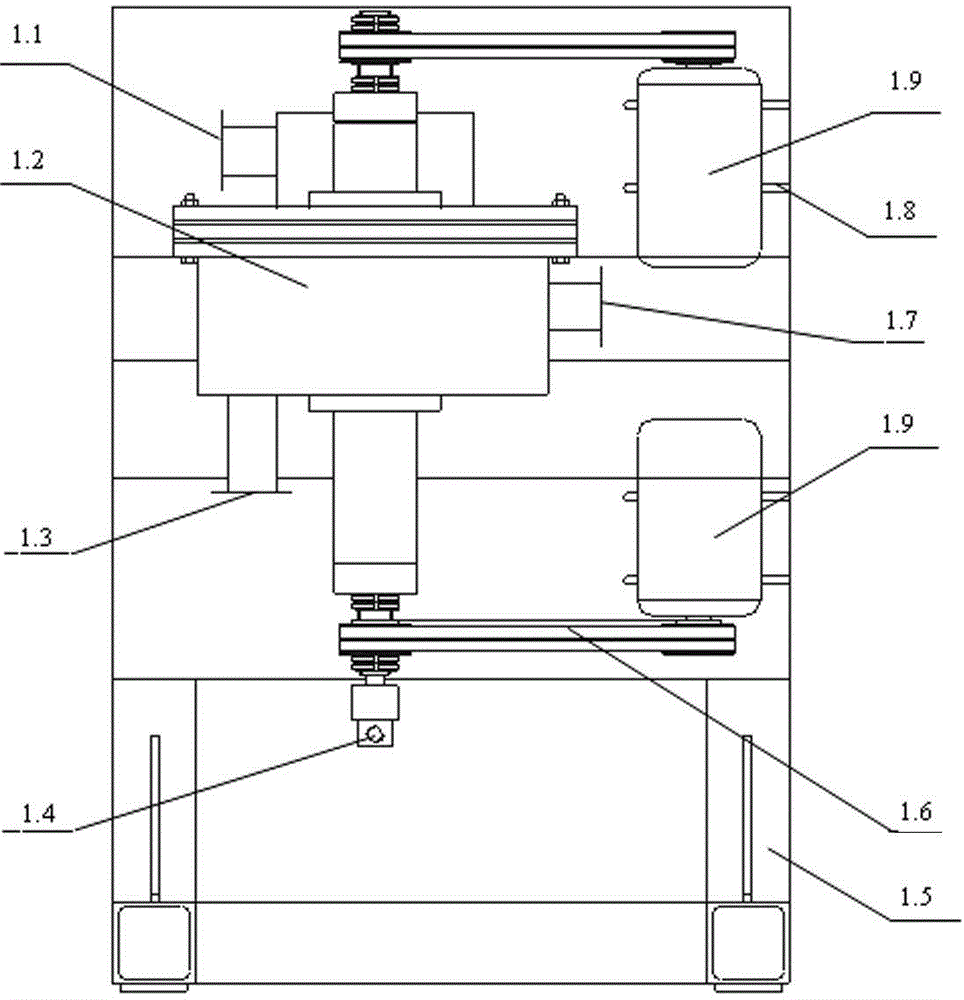

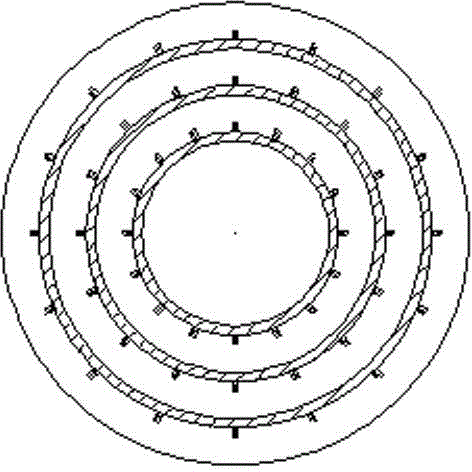

A sulfur dioxide and waste gas technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problem of insignificant improvement of gas phase strengthening effect and mass transfer coefficient, increase of interphase area and surface renewal rate, and industrial application of desulfurization technology gap and other problems, to achieve the effect of wide processing gas range, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: Set the upper and lower turntables of the rotary packed bed absorber 1 to rotate in reverse, the speed is 400 r / min, ethanolamine lactate ionic liquid, SO in the exhaust gas 2 The concentration is 0.3%, and the exhaust gas flow rate is 150 m 3 / h, the liquid-gas ratio is 0.8 L / m 3 , the absorption reaction temperature is 30°C, and the exhaust gas desulfurization rate is higher than 99.3%.

Embodiment 2

[0054] Embodiment 2: Set the upper and lower turntables of the rotary packed bed absorber 1 to rotate in reverse, the speed is 600 r / min, caprolactam-tetrabutylammonium bromide ionic liquid, SO in the waste gas 2 The concentration is 0.1%, and the exhaust gas flow rate is 160 m 3 / h, the liquid-gas ratio is 0.6 L / m 3 , the absorption reaction temperature is 35°C, and the exhaust gas desulfurization rate is higher than 99.3%.

Embodiment 3

[0055] Example 3: Set the upper and lower turntables of the rotary packed bed absorber 1 to rotate in reverse, the rotation speed is 600 r / min, 1,1,3,3-tetramethylguanidine lactate ionic liquid, SO in the waste gas 2 The concentration is 1%, and the exhaust gas flow rate is 120 m 3 / h, the liquid-gas ratio is 3 L / m 3 , the absorption reaction temperature is 35°C, and the exhaust gas desulfurization rate is higher than 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com