Crank gears for bicycles

A crank drive, bicycle technology, applied in the field of sensor systems, can solve problems such as not being able to withstand mechanical stress, and achieve the effect of a compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

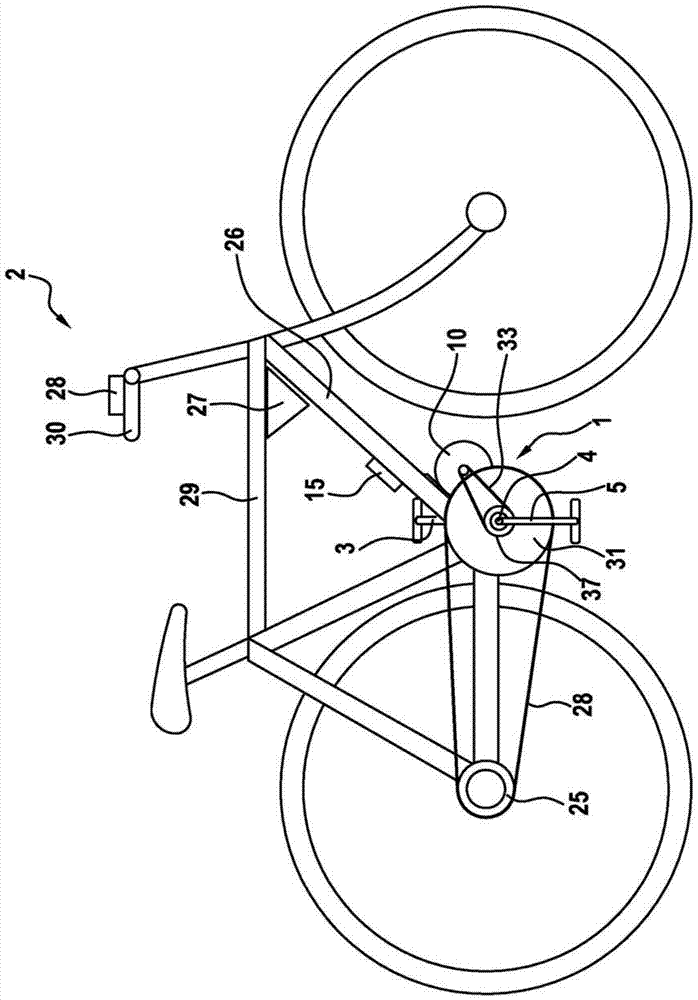

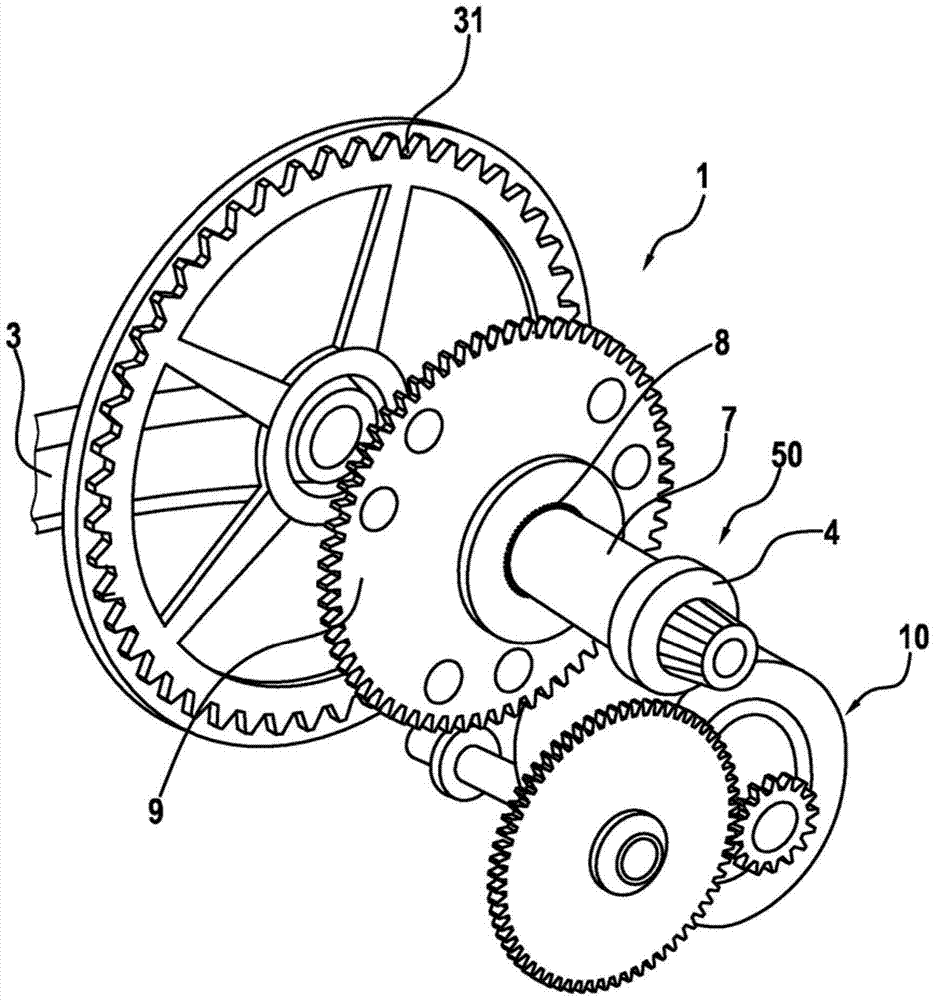

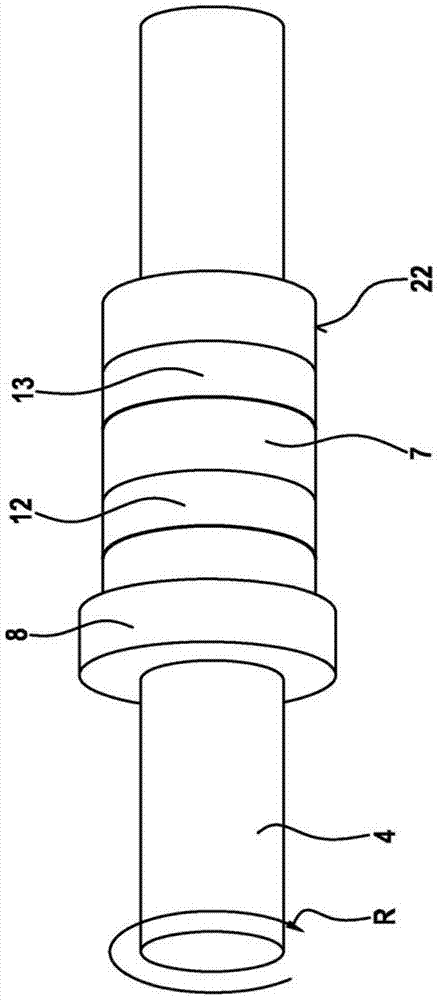

[0031] Refer below Figure 1 to Figure 5 , a crank gear 1 according to the invention for a bicycle and a bicycle with an electric auxiliary drive and a crank gear 1 of this type are described in detail on the basis of a first preferred embodiment.

[0032] figure 1 A schematic illustration of a bicycle 2 with an integrated electrical auxiliary or central drive is shown. as from figure 1 It can be seen that the central drive comprises crank gear 1 , electric or electromotor auxiliary drive 10 , control unit 15 , operating unit 28 and rechargeable energy source 27 . The electric-motor auxiliary drive 10 is arranged below the down tube 26 and in front of the crank gear 1 of the bicycle 2 in the direction of travel and is fixed on the down tube 26 . The crank gear 1 has a pedal crankshaft 4 , to whose free end a pedal crank 3 or a pedal crank 5 is fastened. as from figure 1 It can further be seen that the control unit 15 is fastened to the down tube 26 and communicates with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com