Dyeing method of aramid fiber and aramid fiber after dyeing

An aramid and para-aramid technology, applied in dyeing, textile and paper making, etc., can solve the problems of insufficient dyeing, limited hue, uneven dyeing of dyed products, etc., and achieve rich hue and light fastness. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

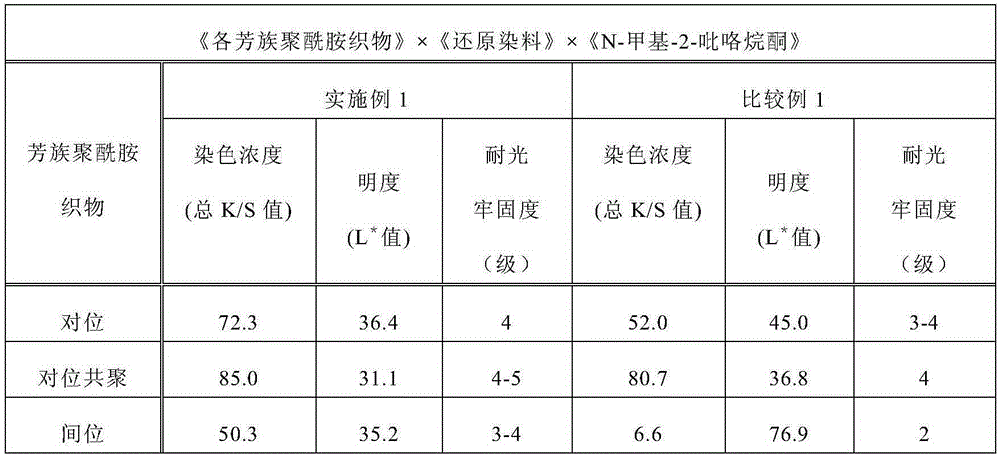

[0055] The dyeing method according to the first embodiment includes a dye imparting step of imparting a vat dye or a sulfur dye to the aramid fiber, and a solvent treatment step of treating the aramid fiber with a treatment liquid containing a polar solvent. The order of the dye imparting step and the solvent treatment step is not particularly limited, but it is preferable to perform the solvent treatment step after the dye imparting step. In the first embodiment, firstly, a dye imparting step of imparting a vat dye or a sulfur dye to the aramid fiber in a non-reduced state is performed, and then the vat dye or sulfur dye is imparted to the aramid fiber with a treatment liquid containing a polar solvent. Solvent treatment process for processing aramid fibers.

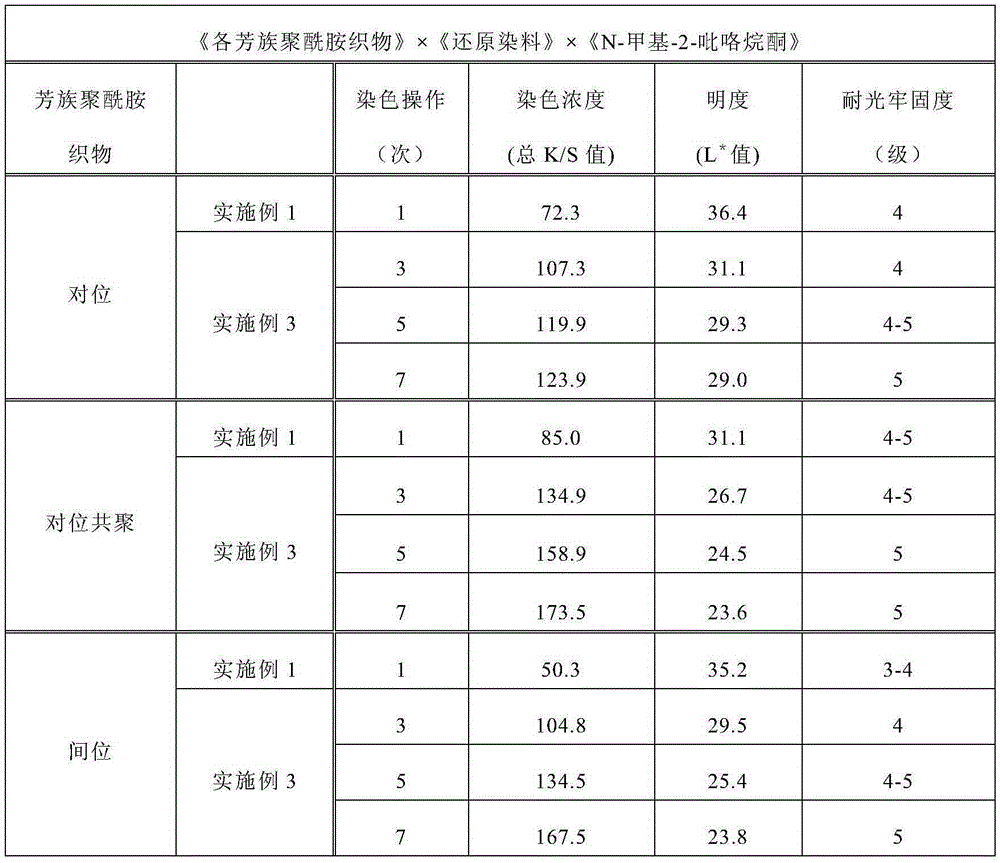

[0056] In this first embodiment, the series of steps described above are collectively referred to as "dyeing operation 1". In addition, this dyeing operation 1 (dye-imparting process→solvent treatment process) may be p...

no. 2 approach

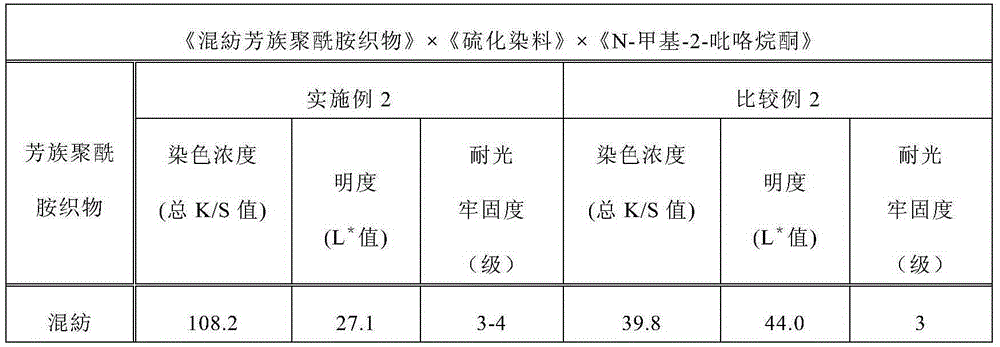

[0083] The dyeing method according to the second embodiment includes: a dye imparting step of imparting a vat dye or a sulfur dye to aramid fibers, a solvent treatment step of treating aramid fibers with a treatment solution containing a polar solvent, and treating the aramid fibers with a solvent. A heat treatment step in which the aramid fiber after the step is heat-treated. In this second embodiment, the series of steps described above are collectively referred to as "dyeing operation 3". In addition, this dyeing operation 3 (dye-imparting process→solvent treatment process→heat treatment process) may be performed only once, or may be repeated multiple times as needed. By repeating this dyeing operation a plurality of times, darker colored aramid fibers can be obtained.

[0084] A. Dye imparting process

[0085] The dye application process in this 2nd Embodiment performs the same operation as the dye application process in the said 1st Embodiment.

[0086] B. Solvent trea...

no. 3 approach

[0098] The dyeing method of the present third embodiment, before the dyeing operation 1 or the dyeing operation 3 explained in the above-mentioned first embodiment or the above-mentioned second embodiment, has the method of using dyes other than vat dyes and sulfur dyes to para-aramid fibers. A pre-dyeing process for dyeing. It should be noted that the above-mentioned dyeing operation 1 or dyeing operation 3 performed after the pre-dyeing process may be performed only once, or may be repeated multiple times as necessary. By repeating this dyeing operation 1 or dyeing operation 3 a plurality of times, darker colored aramid fibers can be obtained.

[0099] D1. Pre-dyeing process

[0100] In the dyeing method of the third embodiment, first, the undyed aramid fiber is subjected to a pre-dyeing step. In this pre-dyeing process, a dyeing solution containing dyes other than vat dyes and sulfur dyes is used. The dyeing method in this pre-dyeing step may be any method, but dyeing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com