A Method for Measuring Mask Plate and Overlay Accuracy

A technology of overlay accuracy and measurement method, which is applied in the field of measurement of mask plate and overlay accuracy, and can solve problems such as uncontrollable overlay accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

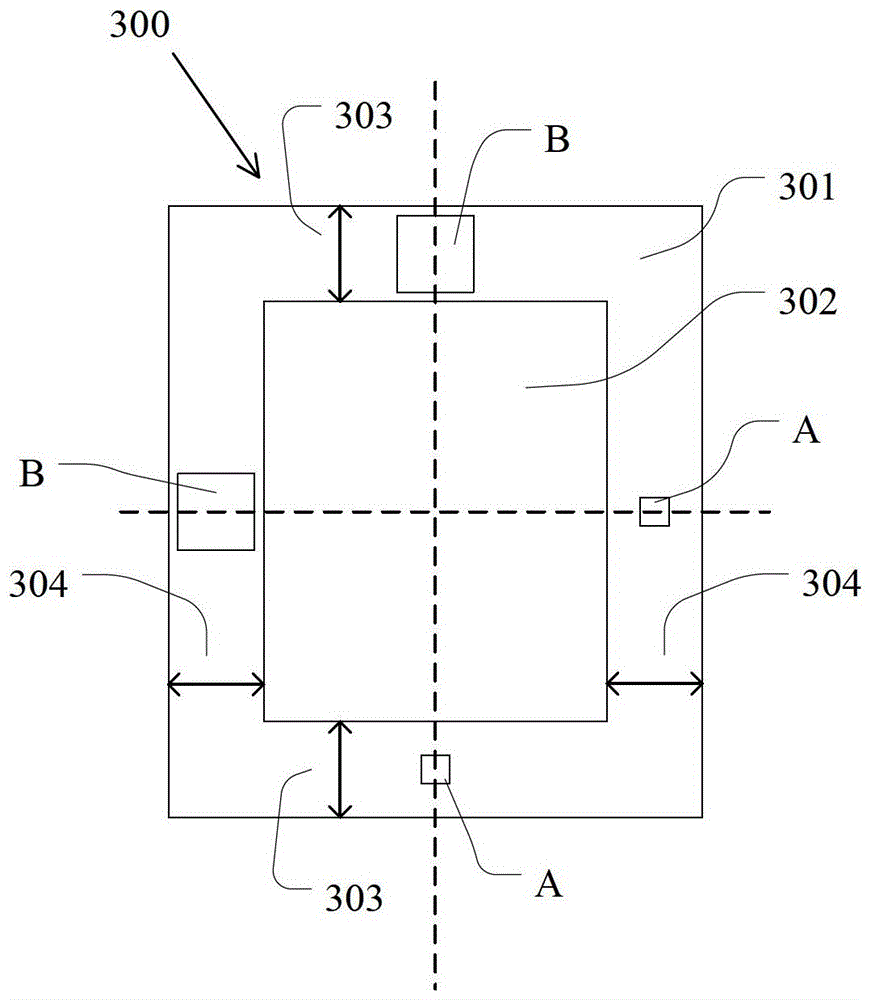

[0032] Such as image 3 As shown, this embodiment provides a mask plate 300, specifically, including a pattern area 302 and a peripheral area 301; the peripheral area 301 has a plurality of first marks A and a plurality of second marks B for alignment , wherein the first mark A and the second mark B have different sizes and / or shapes. In this embodiment, the first mark A and the second mark B have the same shape but different sizes. Specifically, the first mark A and the second mark B are rectangles with different sizes (sizes). In other embodiments of the present invention, the first mark A and the second mark B can also be in other shapes , for example: triangle, rhombus, etc., which are not limited in this application. There are 2 each of the first mark A and the second mark B. As shown in the figure, the order of the first mark A and the second mark B is AABB clockwise. Wherein, the centers of the first mark A and the second mark B on the opposite side are collinear, a...

Embodiment 2

[0035] Such as Figure 5 As shown, this embodiment provides a mask plate 500, specifically, including a pattern area 502 and a peripheral area 501; the peripheral area 501 has a plurality of first marks A and a plurality of second marks B for alignment , wherein the first mark A and the second mark B have different sizes and / or shapes. In this embodiment, the first mark A and the second mark B have the same shape but different sizes. The first mark A and the second mark B are 4 each. As shown in the figure, the first marks A and the second marks B are arranged at intervals. A first mark A and a second mark B are respectively distributed around the peripheral area 501 . Wherein, each first mark A / second mark B is collinear with the center of the second mark B / first mark A on the same side and the second mark B / first mark A on the opposite side, as shown in the figure, the first The center of the second mark B is collinear with the first mark A on the same side and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com