Simulation test system for temperature resistance and pressure resistance of packer rubber sleeve

A simulation test system and packer technology, applied in the field of simulation test, can solve the problems of slow heating speed and low test efficiency, and achieve the effect of fast heating speed, good safety and environmental protection performance, and less equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

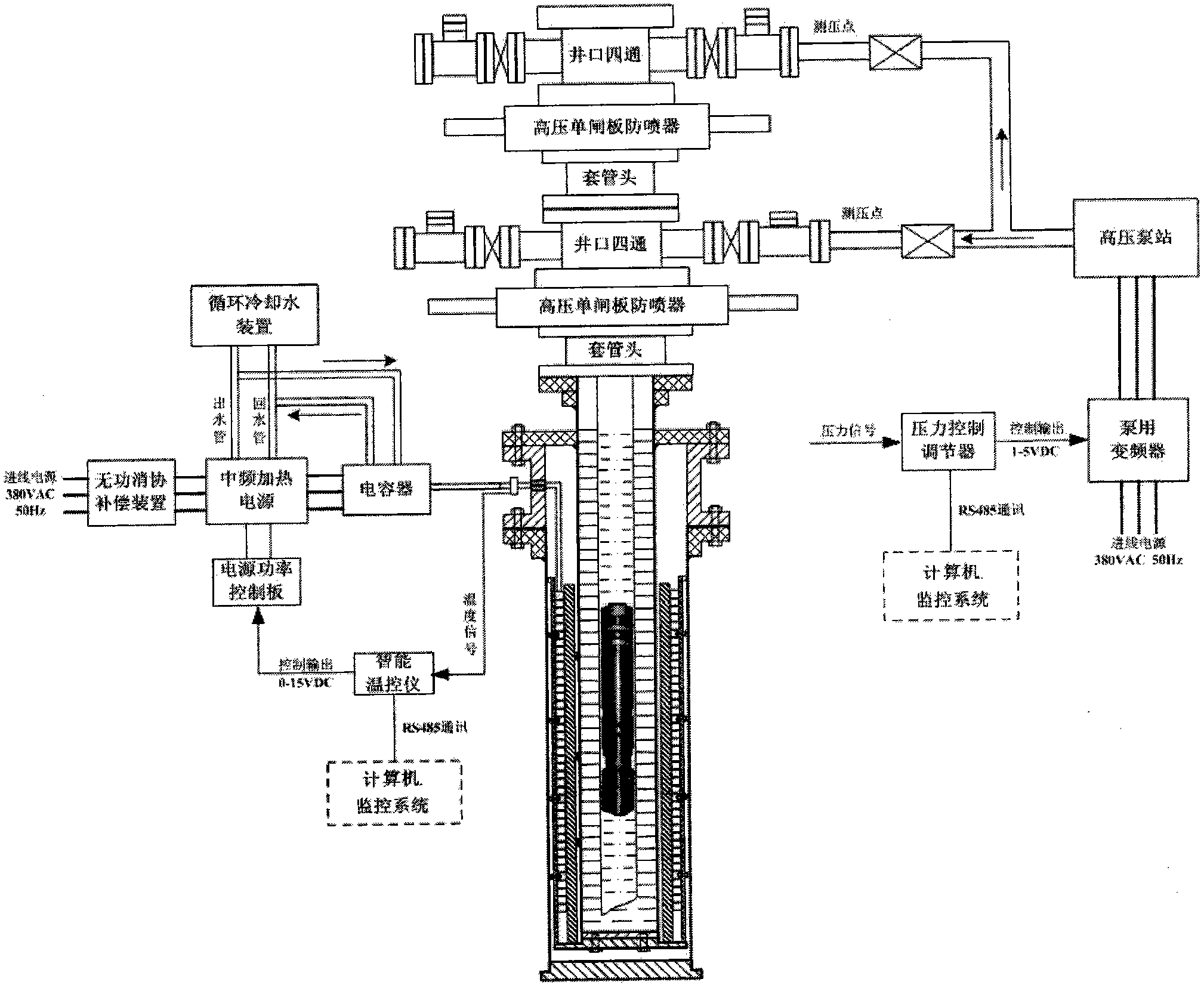

[0022] Such as figure 1 , 2 As shown in , 3, a simulation test system for the temperature and pressure resistance performance of a packer rubber cylinder mainly includes a casing induction heating device 100 , an intermediate frequency power supply and control system 200 , a pressurizing device, and a computer monitoring system 400 .

[0023] The casing induction heating device 100 is the core of the whole system, and other parts are connected with it through corresponding interfaces, and the downhole tool to be tested completes the pressure heating test in the heating casing. The induction heating mechanism on the surface of the heating casing is connected to the intermediate frequency power supply and the control system 200 through the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com