Improved forklift drive axle test board and testing method thereof

A technology of drive axle and test bench, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem that the difference in the detection value of the drive axle is large, the transmission efficiency cannot be detected, the braking and differential function detection, and the performance of the whole vehicle cannot be guaranteed. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

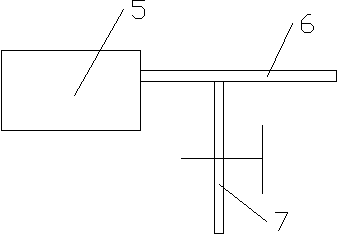

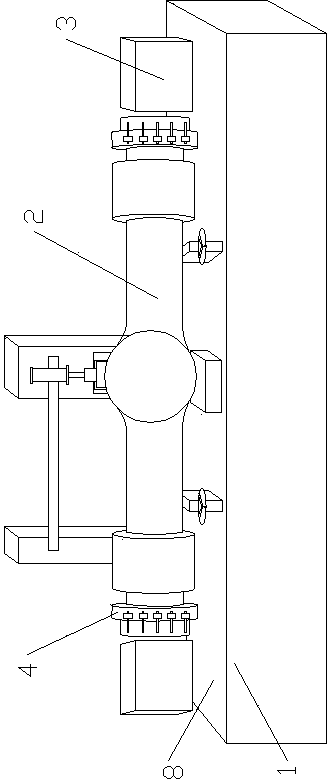

[0017] like figure 1 and figure 2 As shown, an improved forklift drive axle test bench includes a test bench body 1, a drive axle mounting platform 8 is arranged on the test bench body 1, and a load loading device is provided at both ends of the mounting platform 8. The load The loading device is a magnetic powder loader 3, and the inside of the test bench body 1 includes a brake, the brake is connected with an oil cylinder 5, the oil cylinder 5 is connected with a brake device, and the brake device is an oil pipe 6 connected to the oil cylinder 5 The air pipe 7 on the top and the magnetic powder loader 3 are respectively connected with the drive wheels 4 at both ends of the forklift drive axle installed on the test bench body 1 through the transmission shaft.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com