Configuration design method of switching control system

A technology of control system and design method, applied in the control of superheat temperature, lighting and heating equipment, steam superheating, etc., can solve the problems of long adjustment time and poor self-adaptive ability, and achieve the improvement of response, poor self-adaptive ability, Improve the effect of long conditioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

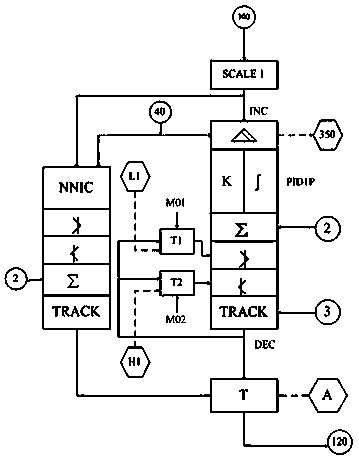

[0019] Embodiment one: see figure 1 As shown, a configuration design method of a switching control system, based on the DCS control platform, uses the secondary desuperheater for temperature control. The design value of the inlet temperature, the input of the auxiliary control loop is the outlet temperature of the first-stage superheater desuperheater, the output controls the water spray adjustment valve of the first-stage desuperheater, and the set value of the main control loop of the second-stage desuperheater water spray is the main steam temperature , the input signal of the secondary control loop is the temperature after the secondary spray desuperheater;

[0020] The controller adopts a cascade control system, the main controller adopts a neural network intelligent controller, the secondary controller adopts a PID controller, and the output ends of the main ring PID controller and the neural network intelligent controller are both provided with a tracking module.

Embodiment 2

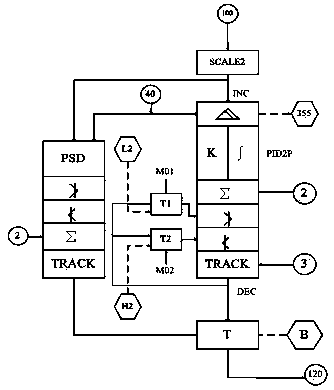

[0021] Example 2: The coal-fired boiler of #2 furnace 600MW unit of a thermal power plant, the DCS system of this unit retains the secondary loop PID control of the original cascade control, and performs non-disruptive switching between the main loop PID controller and the neural network intelligent controller .

[0022] see figure 2 As shown, the configuration design process of side 1A (side A of the primary desuperheater): when the control system is in the automatic control mode, the secondary loop PID control of the primary desuperheater is retained, and the neural network intelligent controller is used to control the original main loop. Outlet temperature of the 1A side of the loop PID control. In the case of manual operation of the 1A side, the control system always tracks the output of the 1A side and the control value of the first-stage desuperheater in the field operation, so as to avoid large interference and errors when switching to the automatic operation of the 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com