Electrospinning device with bi-layer petal-shaped nozzle

An electrospinning, petal-shaped technology, used in spinneret assemblies, textiles and papermaking, filament/thread forming, etc., can solve problems such as low production efficiency and uneven flow, control flow, and improve spinning. Efficiency, effect of fine fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

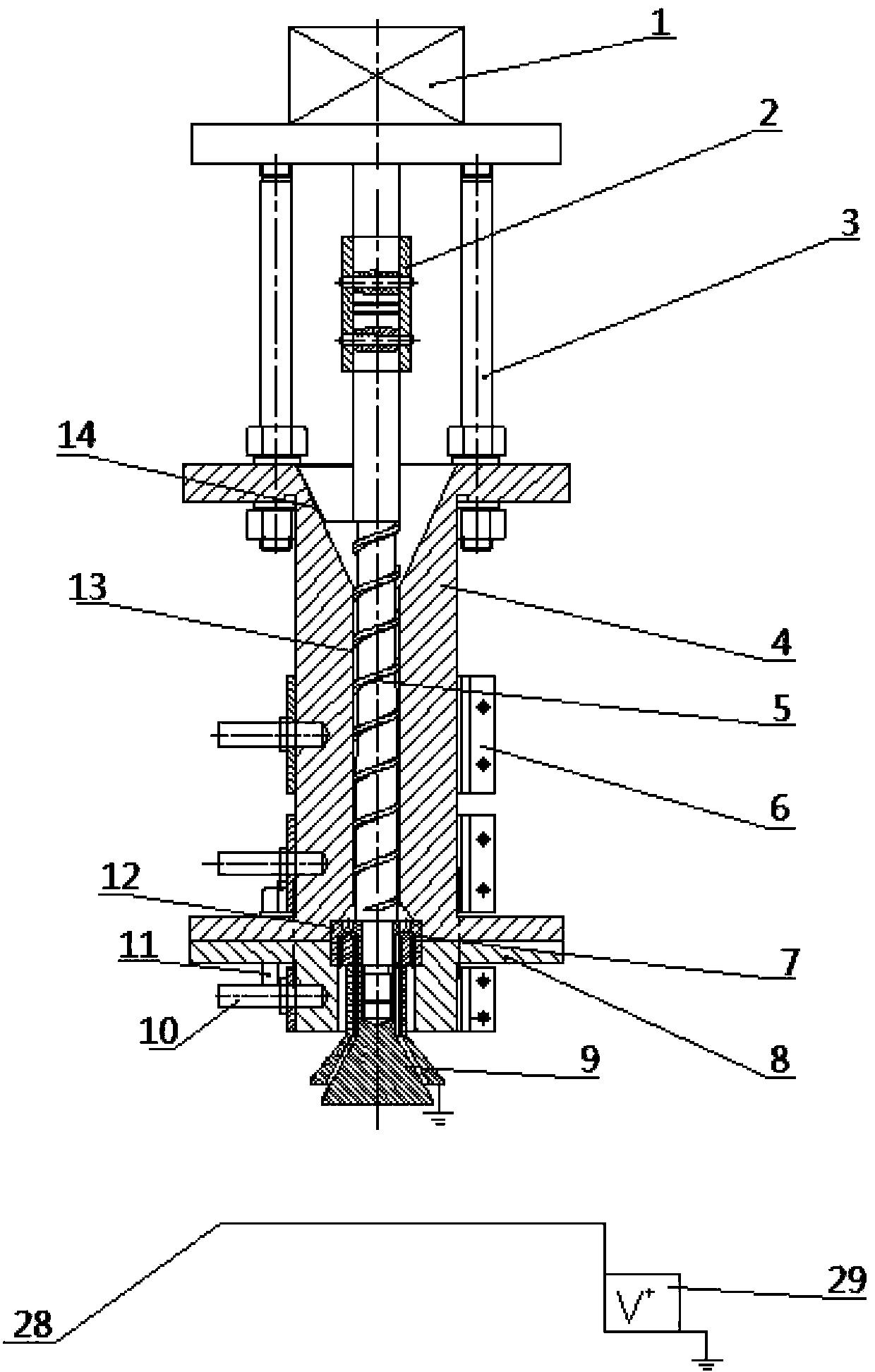

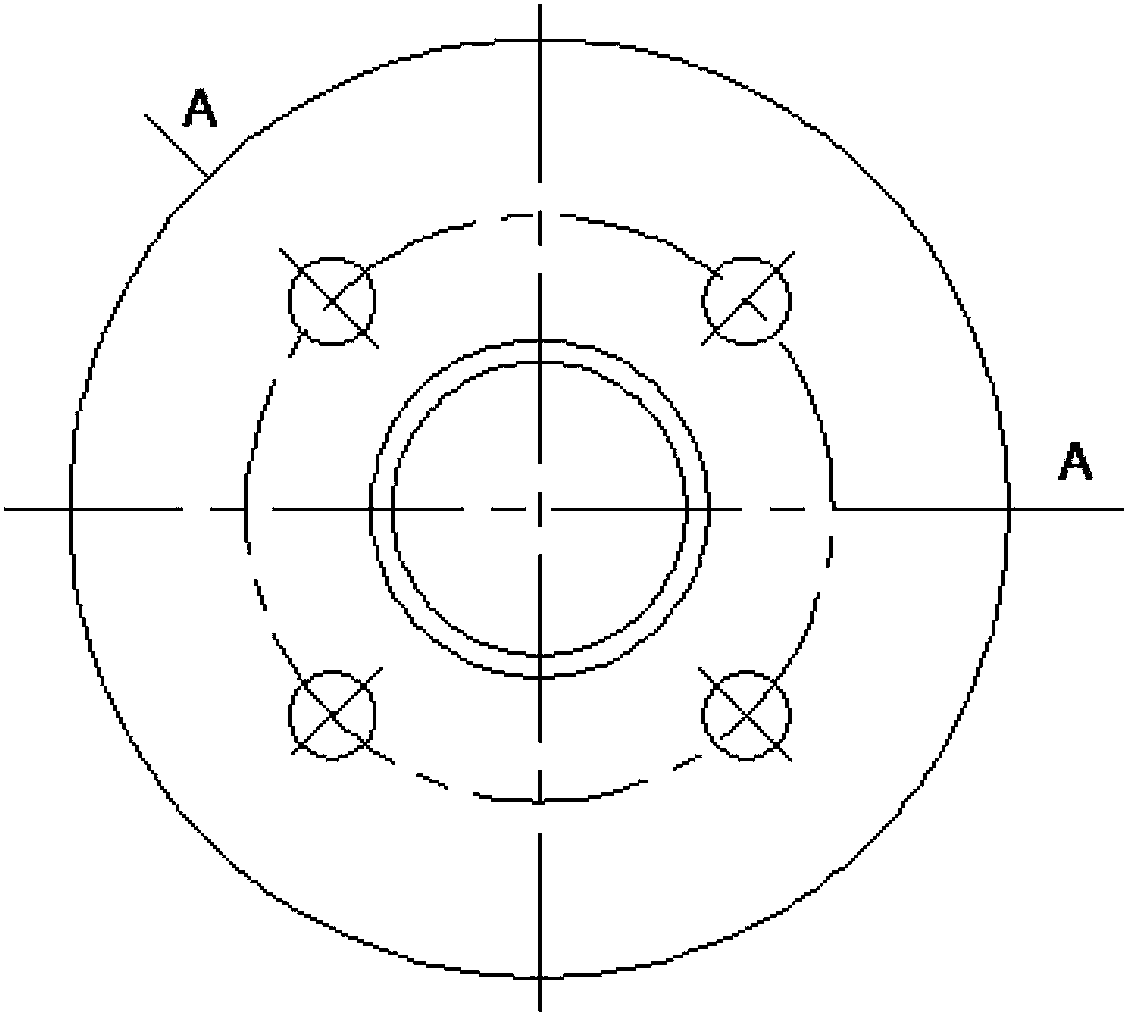

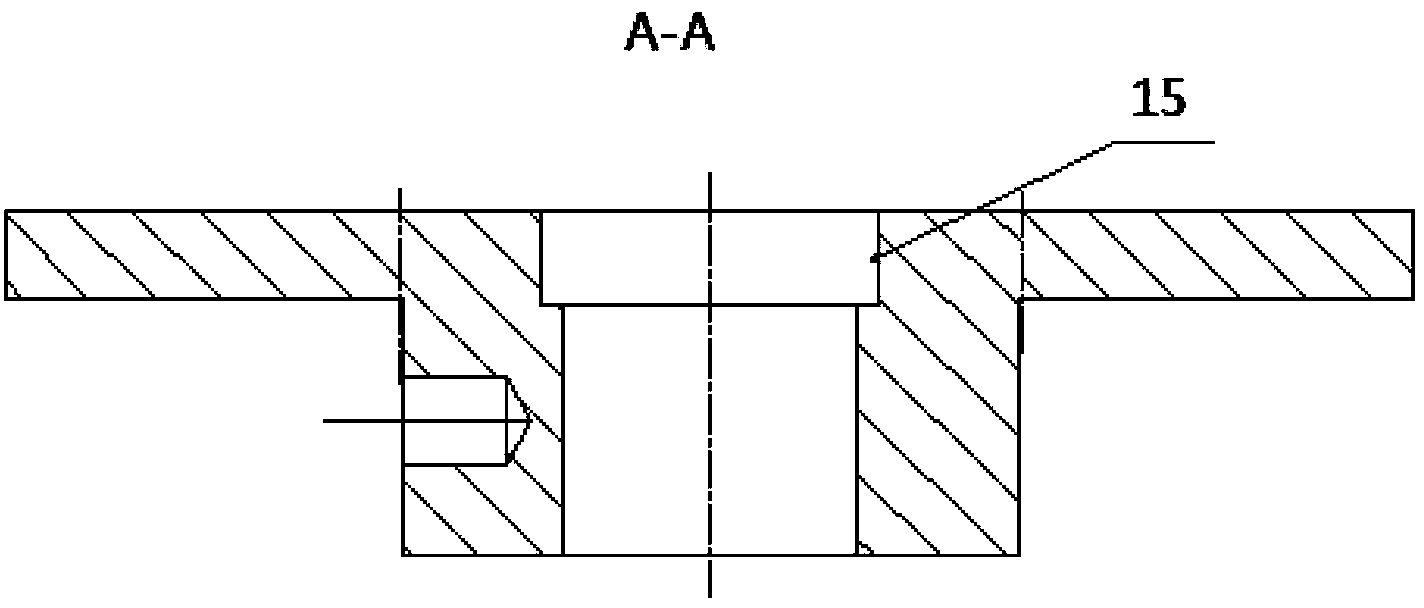

[0021] The electrospinning device of a kind of double-layer petal-shaped nozzle of the present invention, as figure 1 As shown, the device mainly includes a motor 1, a coupling 2, an upper barrel 4, a screw 5, a heating ring 6, a copper ring sliding bearing 7, a lower barrel 8, a nozzle 9, a receiving device 28 and a high-voltage electrostatic generator 29 . The working process is that the motor 1 drives the screw 5 to rotate in the barrel, and at the same time drives the nozzle 9 to rotate, so that the molten polymer is evenly distributed on the two walls of the nozzle 9, and the high-voltage electrostatic generator 29 is turned on. A Taylor cone is formed on the petal, and the voltage is increased, and the Taylor cone sprays to form a jet, which falls to the receiving device 28 to form a fiber.

[0022] The present invention is an electrospinning device with a double-layer petal-shaped nozzle. Firstly, the three heating rings 6 are respectively set at three temperature leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com