Method for Aspergillus oryzae to secrete lignin to prepare peroxidase

A technology of peroxidase and lignin, which is applied in the crude product field of lignin peroxidase, and can solve problems such as unseen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

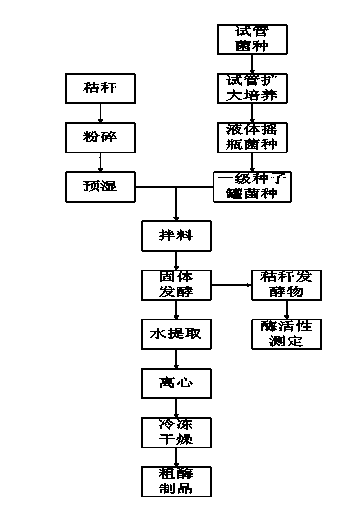

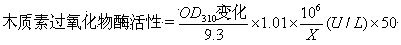

Method used

Image

Examples

Embodiment 1

[0029] 1. Production of bacteria on test tube slant

[0030] Insert a ring of Aspergillus oryzae (Aspergillus oryzae) into the newly configured potato sucrose medium ("Industrial Microbiology Experimental Technology Manual" edited by Zhuge Jian and Wang Zhengxiang, 1994, page 367) (China Common Microbial Cultures Preservation Management Center, CGMCC5992), 26°C, incubation time 50 hours; store at 4°C for later use.

[0031] 2. Production of cultured strains in liquid shake flasks

[0032]Accurately weigh 5 grams of glucose, 0.1 grams of ammonium tartrate, 0.2 grams of benzyl alcohol, 0.2 grams of magnesium sulfate, 0.5 grams of Tween 80, 2 grams of potassium dihydrogen phosphate, 3 grams of phthalic acid buffer, 1000 mL of water, pH 5 , divided into 250mL triangular flasks, 50 grams per bottle, a total of 20 bottles, sterilized at 120 °C for 40 minutes; after cooling, each bottle was inserted into a ring of Aspergillus oryzae strains preserved at 4 °C, at 25 °C, 150 rpm, Cul...

Embodiment 2

[0042] 1. Production of bacteria on test tube slant

[0043] Insert a ring of Aspergillus oryzae into the newly configured potato sucrose medium ("Industrial Microbiology Experimental Technology Manual" edited by Zhuge Jian and Wang Zhengxiang, 1994, page 367), at 30°C, and cultivate for 100 hours ; Store at 7°C for later use.

[0044] 2. Production of cultured strains in liquid shake flasks

[0045] Accurately weigh 150 grams of glucose, 250 grams of ammonium tartrate, 15 grams of benzyl alcohol, 0.4 grams of magnesium sulfate, 4 grams of Tween 80, 5 grams of potassium dihydrogen phosphate, 20 grams of phthalic acid buffer, 10 L of water, pH 6, Divide into 250mL triangular flasks, 100 grams per bottle, 100 bottles in total, sterilize at 130°C for 30 minutes; after cooling, insert a ring of Aspergillus oryzae strains preserved at 7°C, and cultivate 50 hours;

[0046] 3. Preparation of first-level liquid strains

[0047] Accurately weigh 2000 grams of glucose, 200 grams of ...

Embodiment 3

[0055] 1. Production of bacteria on test tube slant

[0056] Insert a ring of Aspergillus oryzae into the newly configured potato sucrose medium ("Industrial Microbiology Experimental Technology Manual" edited by Zhuge Jian and Wang Zhengxiang, 1994, page 367), at 35°C, and cultivate for 144 hours ; Store at 10°C for later use.

[0057] 2. Production of strains cultured in liquid shake flasks

[0058] Accurately weigh 300 grams of glucose, 50 grams of ammonium tartrate, 30 grams of benzyl alcohol, 10 grams of magnesium sulfate, 100 grams of Tween 80, 90 grams of potassium dihydrogen phosphate, 180 grams of phthalic acid buffer, 10 L of water, pH7.5 , divided into 250mL triangular flasks, each bottle 120 mL, a total of 80 bottles, sterilized at 140 ° C for 20 minutes; after cooling, each bottle was inserted into a ring of Aspergillus oryzae strains stored at 10 ° C, at 35 ° C, 150 rpm, Cultivate for 72 hours;

[0059] 3. Preparation of first-level liquid strains

[0060] Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com