Method for diagnosing fluctuation reason of quality of coke

A technology for coke quality and coke, which is applied in the field of diagnosing the causes of fluctuations in coke quality, can solve problems such as rising coal blending costs and waste of high-quality resources, and achieve the effects of saving coal blending costs and reducing energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] From 0-8:00 on February 27, 2013, the coke quality index of Shanxi Taigang Stainless Steel Co., Ltd. Coking Plant fluctuated for 5 consecutive shifts. It means that the coke particle size and diameter are larger than 40mm), and the coke agglomeration becomes smaller. The specific indicators are shown in the following table.

[0012] Coke quality index (Table 1)

[0013]

[0014] The various problems of coke during quality fluctuations are listed and the possible causes are analyzed, and the results are shown in the following table:

[0015]

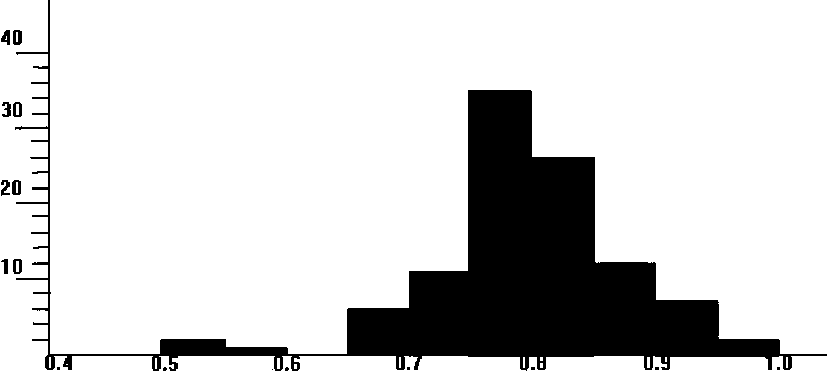

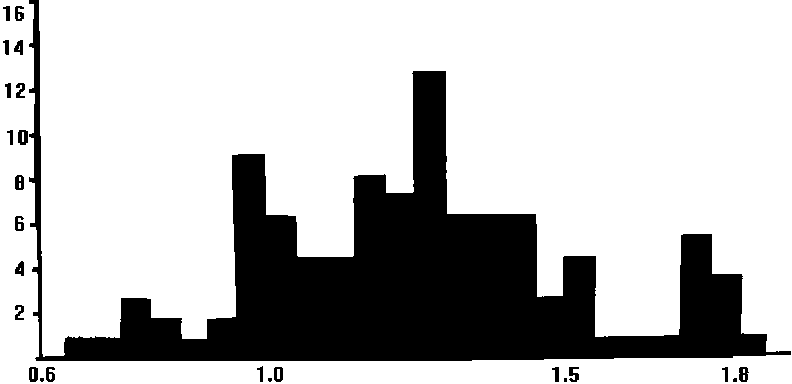

[0016] In view of the reason of the coal blending structure, the vitrinite reflectance of the blended coal on the 27th was randomly checked. The results showed that the content of the low-metamorphic coal in the coal loaded on the 27th increased, and the coal containing the gas coal metamorphic degree was 3%. The results are as follows: figure 1 shown.

[0017] Schematic diagram of vitrinite reflectance distribution Graphic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com