Base material-free optical adhesive tape and its manufacturing method

A manufacturing method, a technology without a base material, applied in the direction of adhesives, film/sheet adhesives, pre-treated surfaces, etc., can solve the problems of multiple man-hours and production costs, increase tape pollution, waste, etc., to avoid visual defects , Improve product quality and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

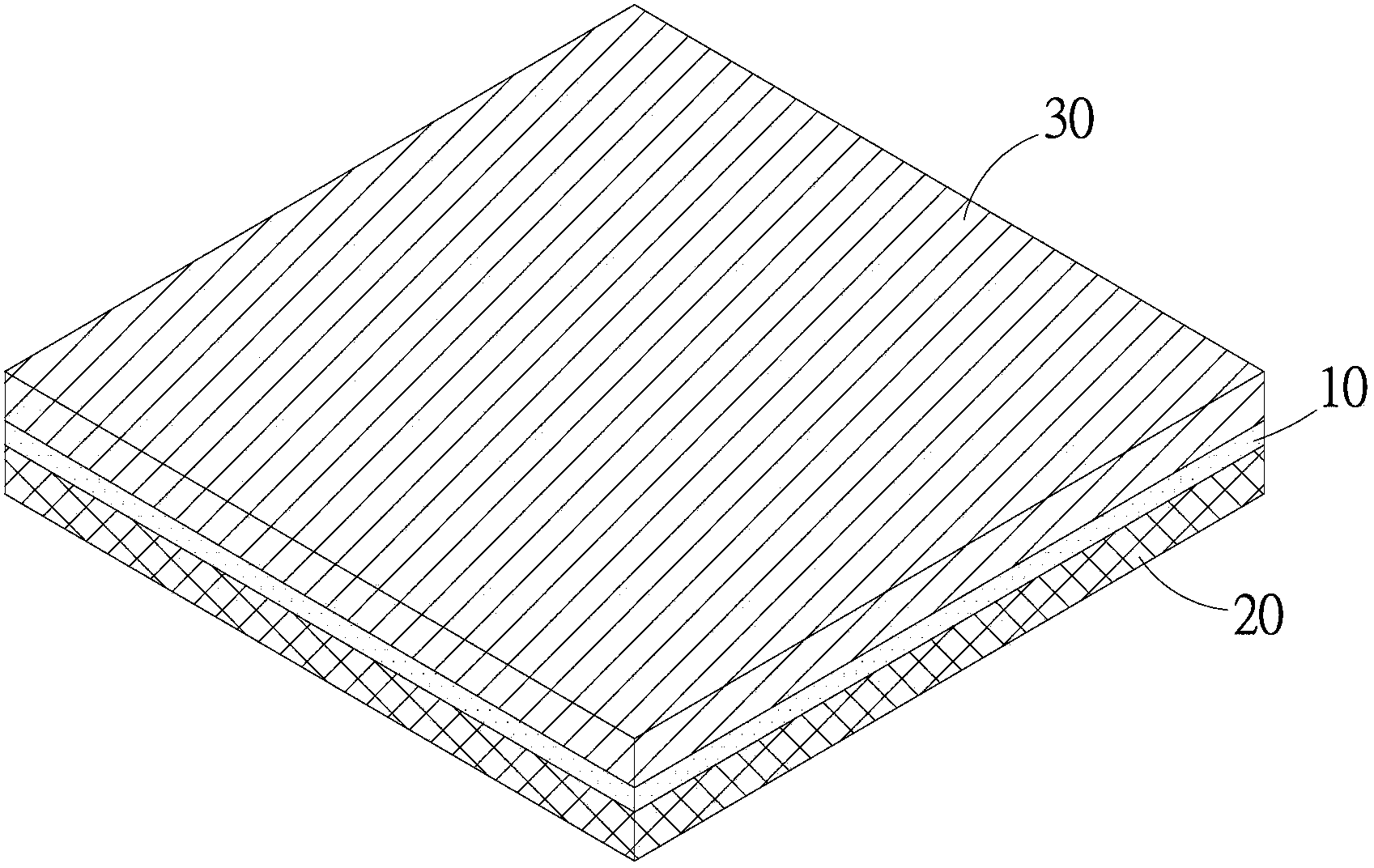

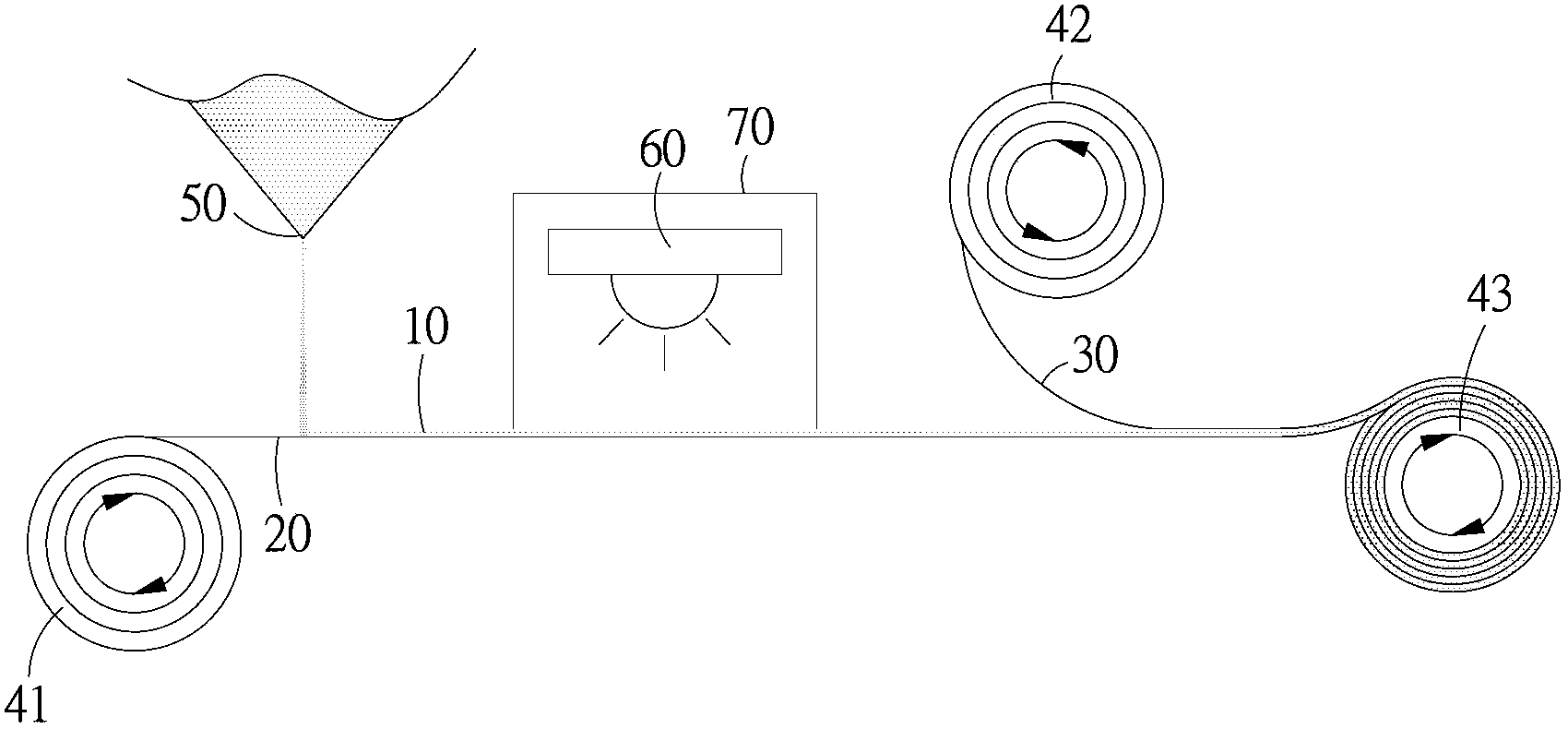

[0036] As shown in the enlarged schematic view of the structure of the substrate-less optical tape of the present invention in Figure 1, the substrate-free optical tape of the present invention is covered with a first release film 20 with a predetermined thickness on both sides of an optical film 10 with a predetermined thickness, and A second release film 30 with a predetermined thickness. Wherein, the optical film 10 is formed by curing a pre-synthesized adhesive material and a film-forming formula of a predetermined weight percentage by UV light; Joint agent, and antioxidant composition.

[0037] As for, the film-forming formulation may have a predetermined weight percentage of photoinitiator. The first release film can be a heavy release film with a thickness of 125 mic; the second release film is a light release film with a thickness of 50 mic, so that the overall substrate-free optical adhesive tape can achieve better structural strength , and can be stored at room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com