Treatment method of reverse osmosis concentrated water of coking wastewater

A technology for reverse osmosis concentrated water and coking wastewater, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Low content and other problems, to achieve the effect of saving pharmaceutical costs, achieving zero discharge, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

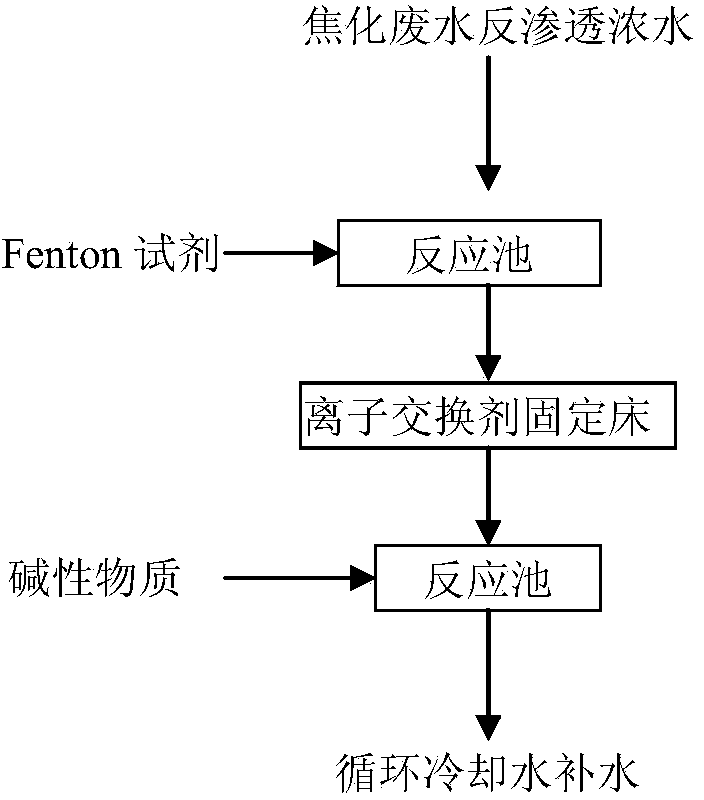

[0032] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

[0033] A: will go through "A 2 O + coagulation and sedimentation" treated coking wastewater is injected into the container, the flow rate is 2m 3 / h;

[0034] B: Coking wastewater is pretreated by "manganese sand filtration + ultrafiltration membrane", and an appropriate amount of scale inhibitor is added;

[0035] C: reverse osmosis for coking wastewater;

[0036] D: Reverse osmosis concentrated water enters the chemical reactor, and Fenton reagent is added to the chemical reactor, H 2 o 2 Addition amount 1~1000mg / L, Fe 2+ The addition amount is 1-200mg / L, and the reaction time is 1-60min.

[0037] E: Concentrated water passes through a fixed bed composed of natural zeolite, the flow rate is 0.1-10m / s, and the reaction time is 1-60min;

[0038] F: Lime milk was added to the wastewater, and 1-100 mg / L was added.

[0039] G: The treated waste water is ...

example 2

[0041] A coking plant has implemented advanced treatment of coking wastewater. After advanced treatment of coking wastewater with the "ultrafiltration membrane + reverse osmosis membrane" process, the reverse osmosis concentrated water is treated as shown in this article. The scale of treated water is 30m 3 / h, COD, the main water quality parameter before treatment, 80-1010mg / L, NH3-N≤4-10mg / L. After treatment, total hardness (calculated as CaCO3)≤450mg / L, Cl-≤250mg / L, CODcr≤60mg / L, NH3-N≤10mg / L. After concentrated water treatment, the various water quality indicators meet the water quality indicators of the circulating cooling water in the intermediate cold open system of the "Industrial Circulating Cooling Water Treatment Design Specification" (GB50050-2007). After the circulating cooling water system has been in operation for a period of time, its corrosion and structural ratios are controlled within the specified range, and the addition of scale inhibitors in the replenish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com