Method for removing phosphorus in concentred and dewatered sludge water by virtue of deeply-dewatered sludge water

A technology of concentrated dehydration and deep dehydration, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, water/sewage multi-stage treatment, etc. High energy consumption, unstable treatment effect, etc., to achieve the effect of reducing pollutant load and reducing pollutant burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention uses deep dewatered sludge water to remove phosphorus in concentrated dewatered sludge water, comprising the following steps:

[0029] Step 1: Pre-precipitate the deep dewatered sludge water and the concentrated dewatered sludge water respectively, and remove the suspended solids in the two sludge waters;

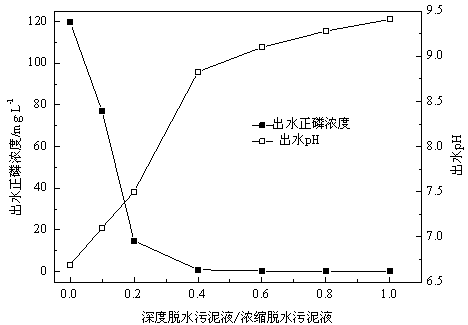

[0030] Step 2: The measured pH of deep dewatered sludge water is 9.91, and the concentration of orthophosphorus is 1.24 mg / L; the pH of concentrated dewatered sludge water is measured to be 6.69, and the concentration of orthophosphorus is 119.80 mg / L;

[0031] Step 3: Take 300mL of concentrated dewatered sludge water, and add different volumes of deep dewatered sludge water according to the volume ratio of deep dewatered sludge water to concentrated dewatered sludge water: 1, 0.8, 0.6, 0.4, 0.2 and 0.1.

[0032] Step 4: Set the rotation speed to 200rpm, stir for 30 minutes, and after standing for 15 minutes, take the supernatant to measure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com