Silver carbonate-graphene oxide composite nano-material, as well as preparation method and application thereof

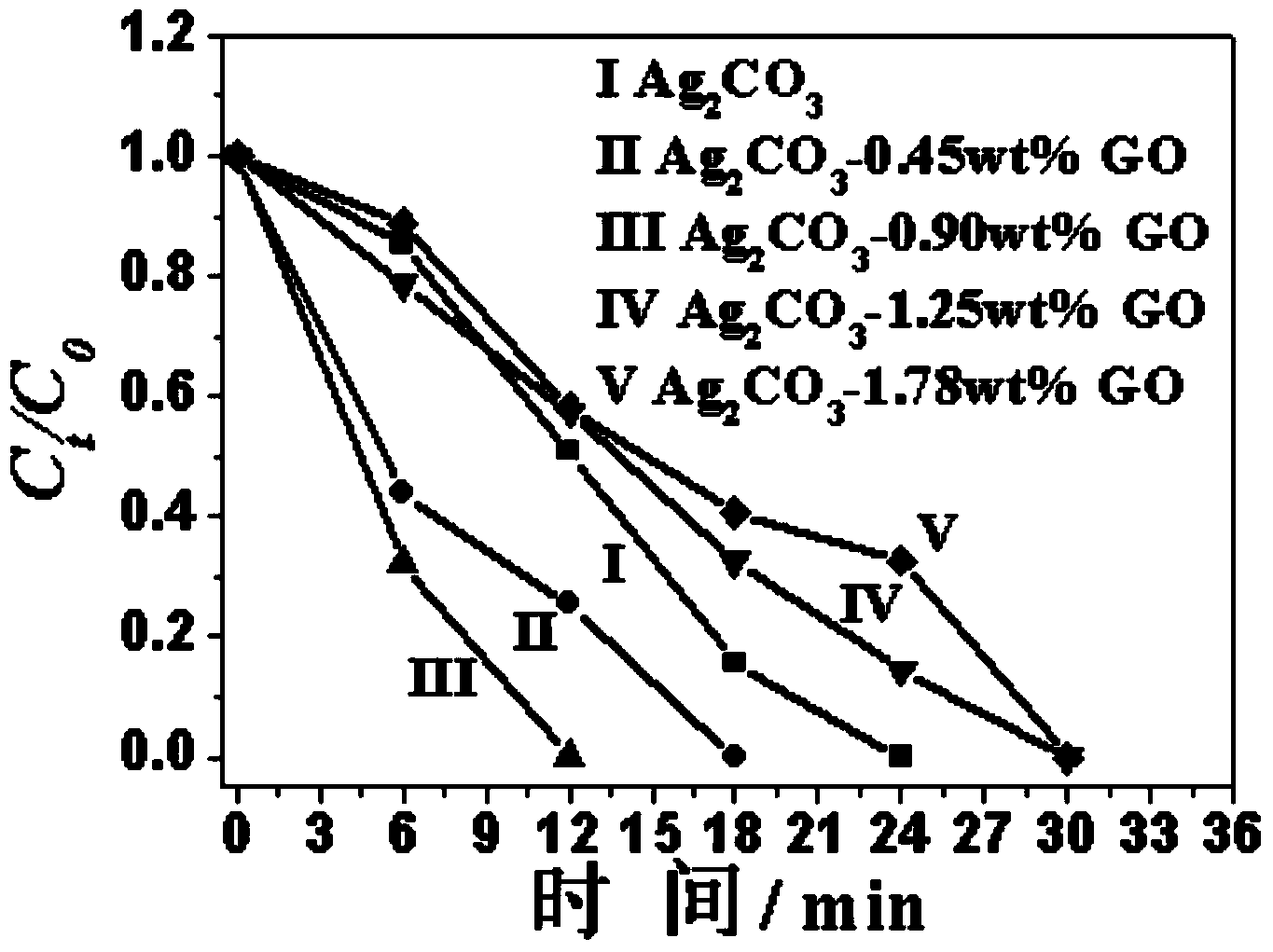

A graphene composite and nano-material technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problem of poor cycle performance of silver carbonate photocatalyst, photocatalytic activity to be improved, and low adsorption performance, etc. problems, achieve good chemical stability, improve photocatalytic activity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

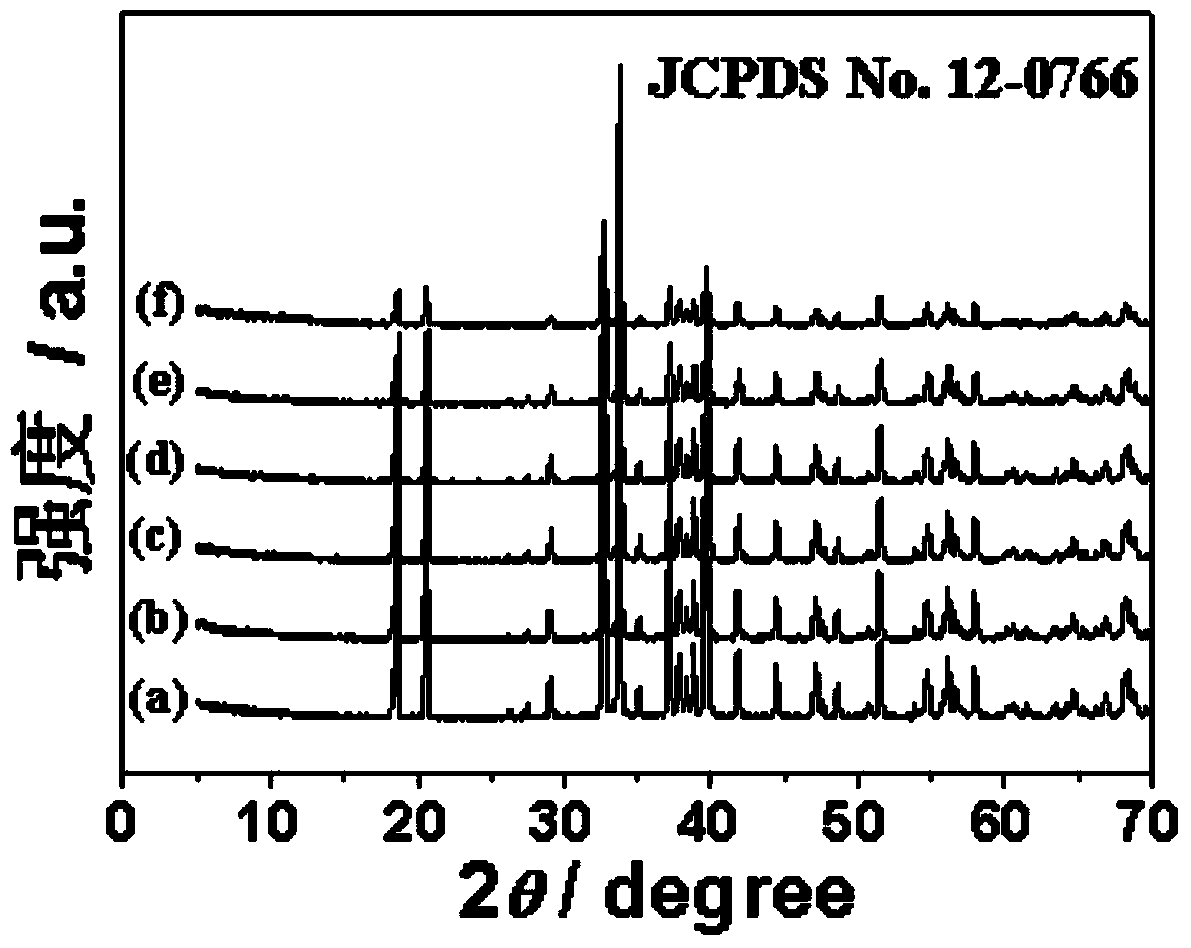

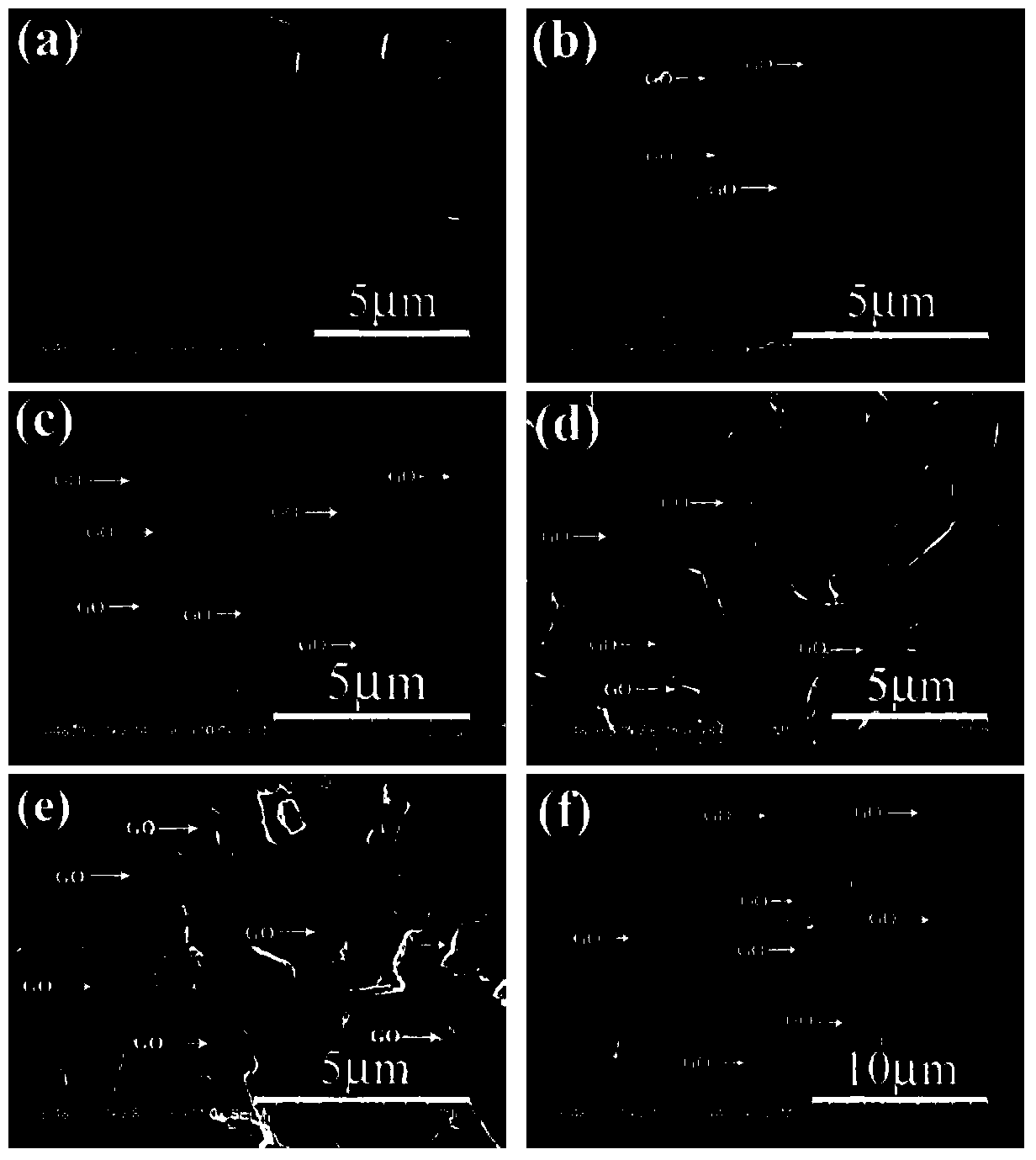

[0031] a kind of Ag 2 CO 3 -Graphene oxide composite nanomaterial, Ag 2 CO 3 The particles are rod-shaped, the graphene oxide is in the form of flakes, and the mass percentage of graphene oxide is 0.45%.

[0032] a kind of Ag 2 CO 3-The preparation method of graphene oxide composite nanomaterial, the steps include:

[0033] A, graphene oxide is ultrasonically dispersed in deionized water for 1h to prepare a graphene oxide dispersion;

[0034] B. Add AgNO to the graphene oxide dispersion under stirring 3 aqueous solution, continue to stir for 0.5h;

[0035] C. Add ammonia solution to the mixed solution prepared in step B under stirring, and continue to stir for 0.3h;

[0036] D. Add NaHCO to the preparation mixture in step C under stirring 3 Solution, continue to stir for 0.25h;

[0037] E. Centrifuge the product obtained in step D, wash the product with deionized water and absolute ethanol, and dry it in vacuum at 60°C for 4 hours to obtain Ag 2 CO 3 - Graphene oxi...

Embodiment 2

[0042] a kind of Ag 2 CO 3 -Graphene oxide composite nanomaterial, Ag 2 CO 3 It is a rod-shaped particle, the graphene oxide is in a flake shape, and the mass percentage of graphene oxide is 0.9%.

[0043] a kind of Ag 2 CO 3 -The preparation method of graphene oxide composite nanomaterial, the steps include:

[0044] A, graphene oxide is ultrasonically dispersed in deionized water for 1h to prepare a graphene oxide dispersion;

[0045] B. Add AgNO to the graphene oxide dispersion under stirring 3 aqueous solution, continue to stir for 1h;

[0046] C, under stirring, add ammonia solution to the mixed solution prepared in step B, and continue to stir for 0.5h;

[0047] D. Add NaHCO to the preparation mixture in step C under stirring 3 Solution, continue to stir for 0.5h;

[0048] E. Centrifuge the product obtained in step D, wash the product with deionized water and absolute ethanol, and dry it in vacuum at 20°C for 24 hours to obtain Ag 2 CO 3 - Graphene oxide comp...

Embodiment 3

[0052] a kind of Ag 2 CO 3 -Graphene oxide composite nanomaterial, Ag 2 CO 3 The particles are rod-shaped, the graphene oxide is in the form of flakes, and the mass percentage of graphene oxide is 1.25%.

[0053] a kind of Ag 2 CO 3 -The preparation method of graphene oxide composite nanomaterial, the steps include:

[0054] A, graphene oxide is ultrasonically dispersed in deionized water for 1h to prepare a graphene oxide dispersion;

[0055] B. Add AgNO to the graphene oxide dispersion under stirring 3 aqueous solution, continue to stir for 1h;

[0056] C, under stirring, add ammonia solution to the mixed solution prepared in step B, and continue to stir for 0.75h;

[0057] D. Add NaHCO to the preparation mixture in step C under stirring 3 Solution, continue to stir for 0.75h;

[0058] E. Centrifuge the product obtained in step D, wash the product with deionized water and absolute ethanol, and dry it in vacuum at 30°C for 20 hours to obtain Ag 2 CO 3 - Graphene o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com