Four-finger setting dies for individual soldier protective glove ironing setting machine

A technology of protective gloves and setting machine, which is applied to gloves, clothing, clothing, etc., can solve the problems of inability to meet mass production, poor ironing and setting effect, and easily damaged heating elements, and achieves shortening of setting time, good setting effect, Rapid heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

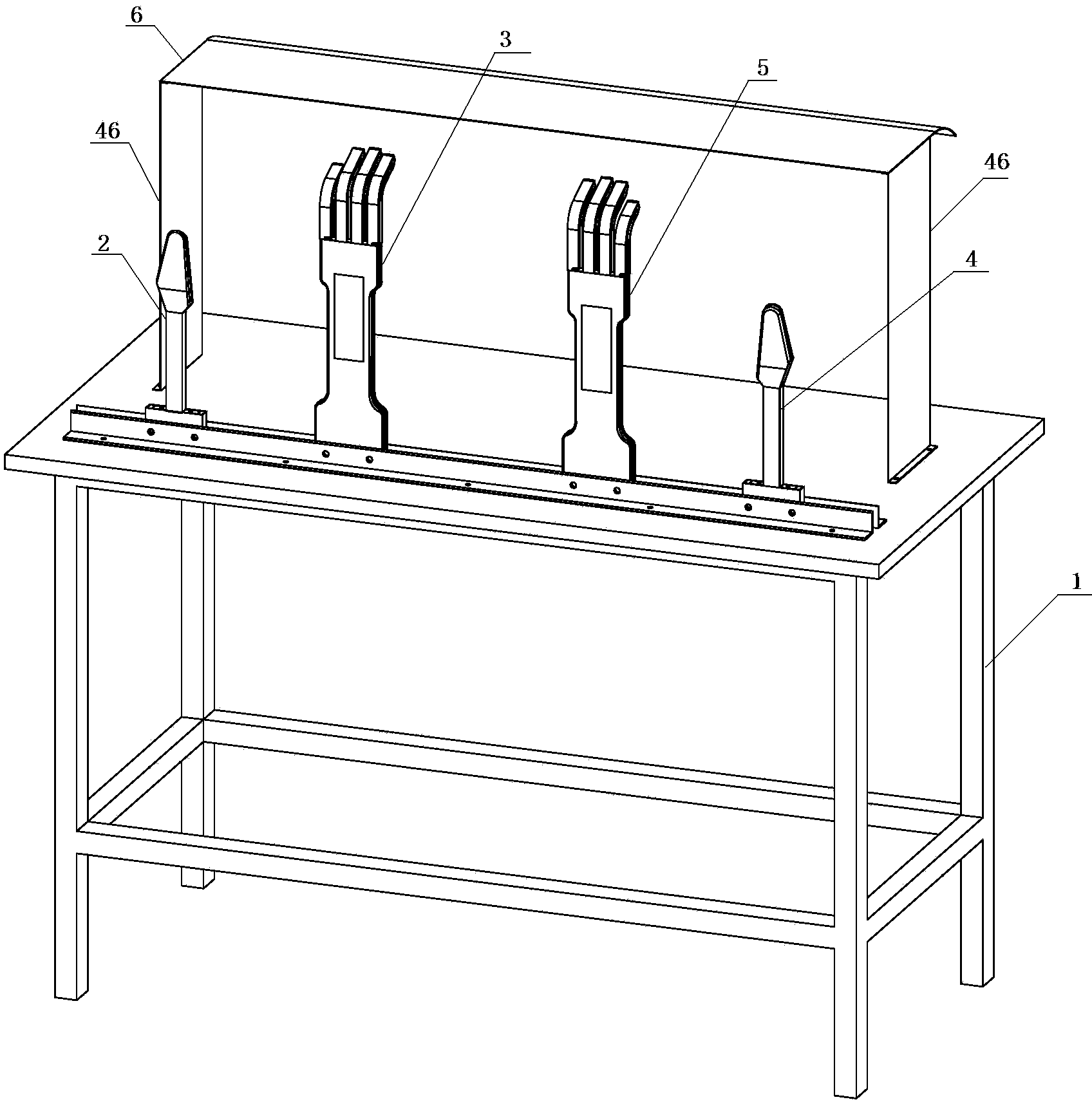

[0014] as attached figure 1 , 2 , 3, the present invention includes a left-hand four-designated mold 3 and a right-hand four-designated mold 5;

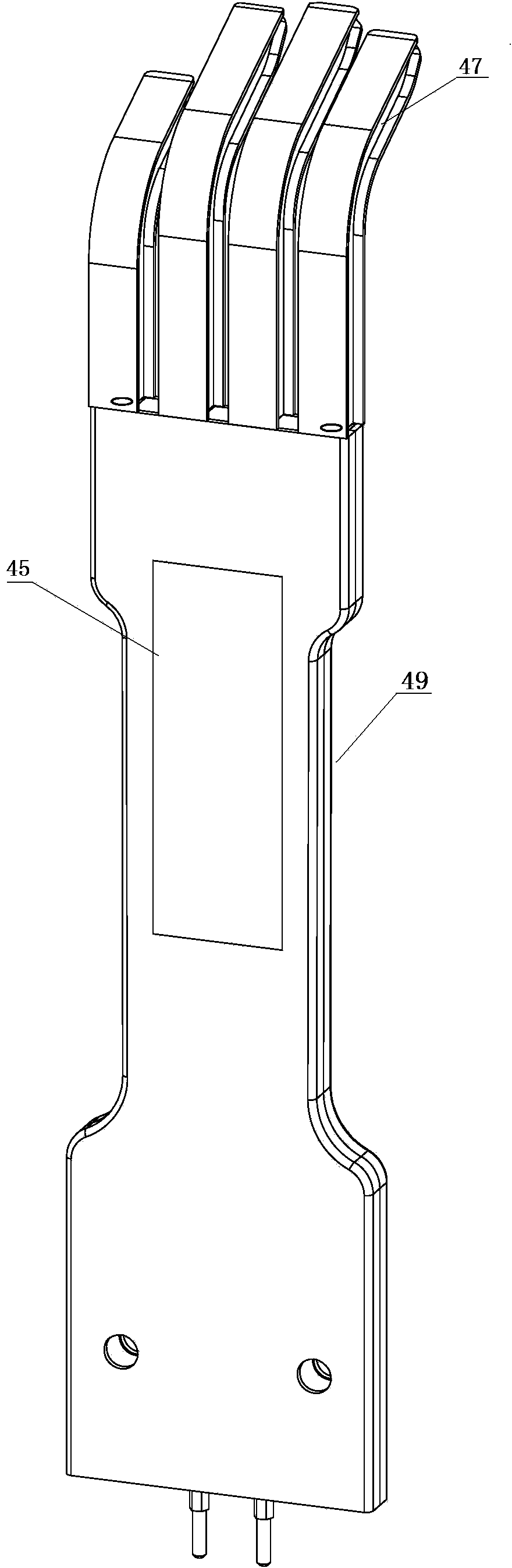

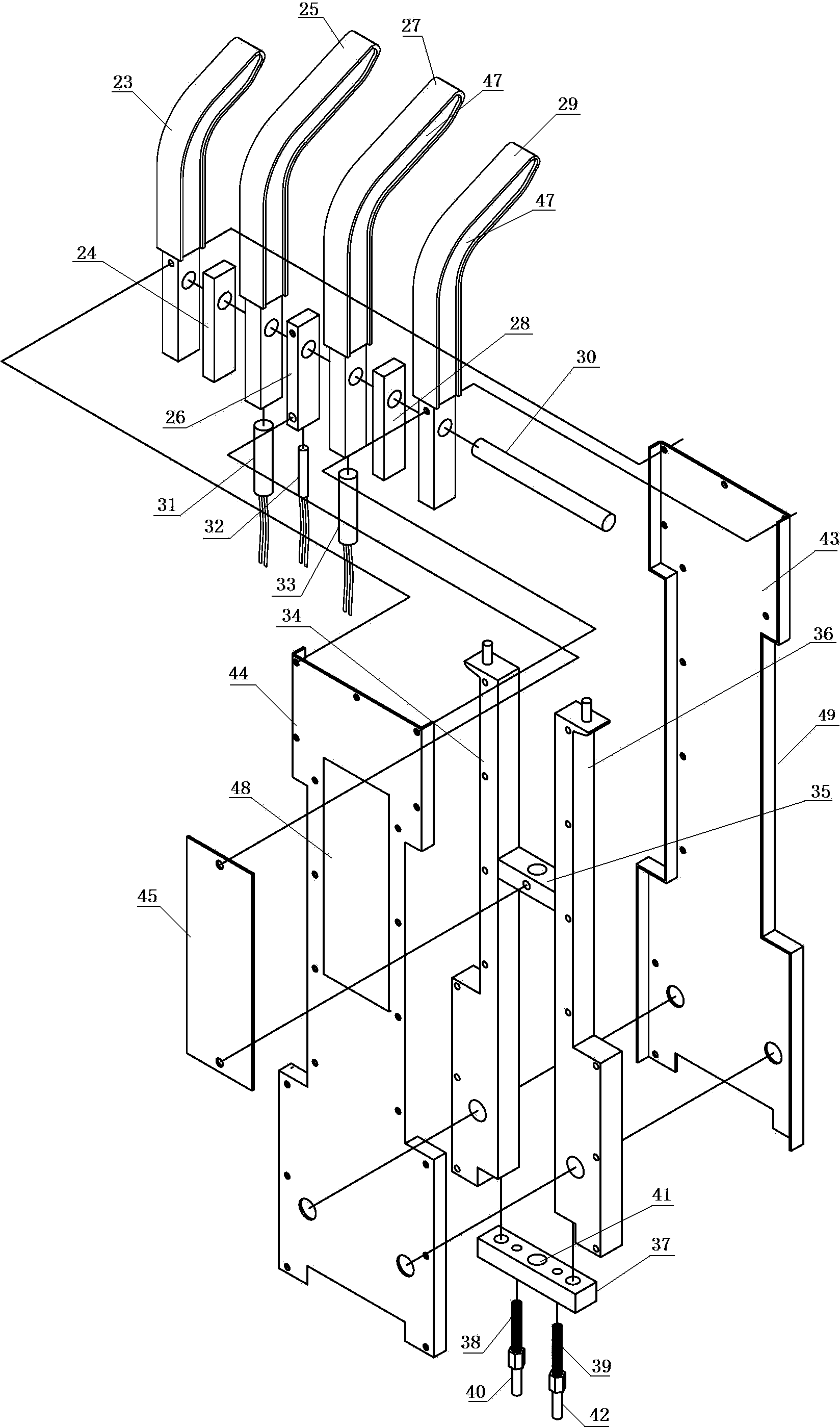

[0015] as attached figure 1 , 2 , 3, the left-hand four-finger mold 3 of the present invention includes a left-hand four-finger heating body, a support seat arranged at the lower end of the left-hand four-finger heating body, an electric heating rod and a second thermocouple arranged in the left-hand four-finger heating body 32. The heating body for the four fingers of the left hand includes, from left to right, the heating body for the little finger 23, the heating body for the ring finger 25, the heating body for the middle finger 27, and the heating body for the index finger 29, which are fixedly connected to each other in sequence. The heating body for the little finger 23, the heating body for the ring finger 25. The upper part of the heating body for the middle finger 27 and the heating body for the index finger 29 is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com