Shearing test piece for researching type II fracture of viscoelastic material under condition of high strain rate

A technology of high strain rate and shearing specimens, applied in the direction of applying stable shear force to test the strength of materials, preparation of test samples, etc., can solve the problems of inapplicability, achieve simple structure, meet the requirements of propagation and calculation methods the effect of the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

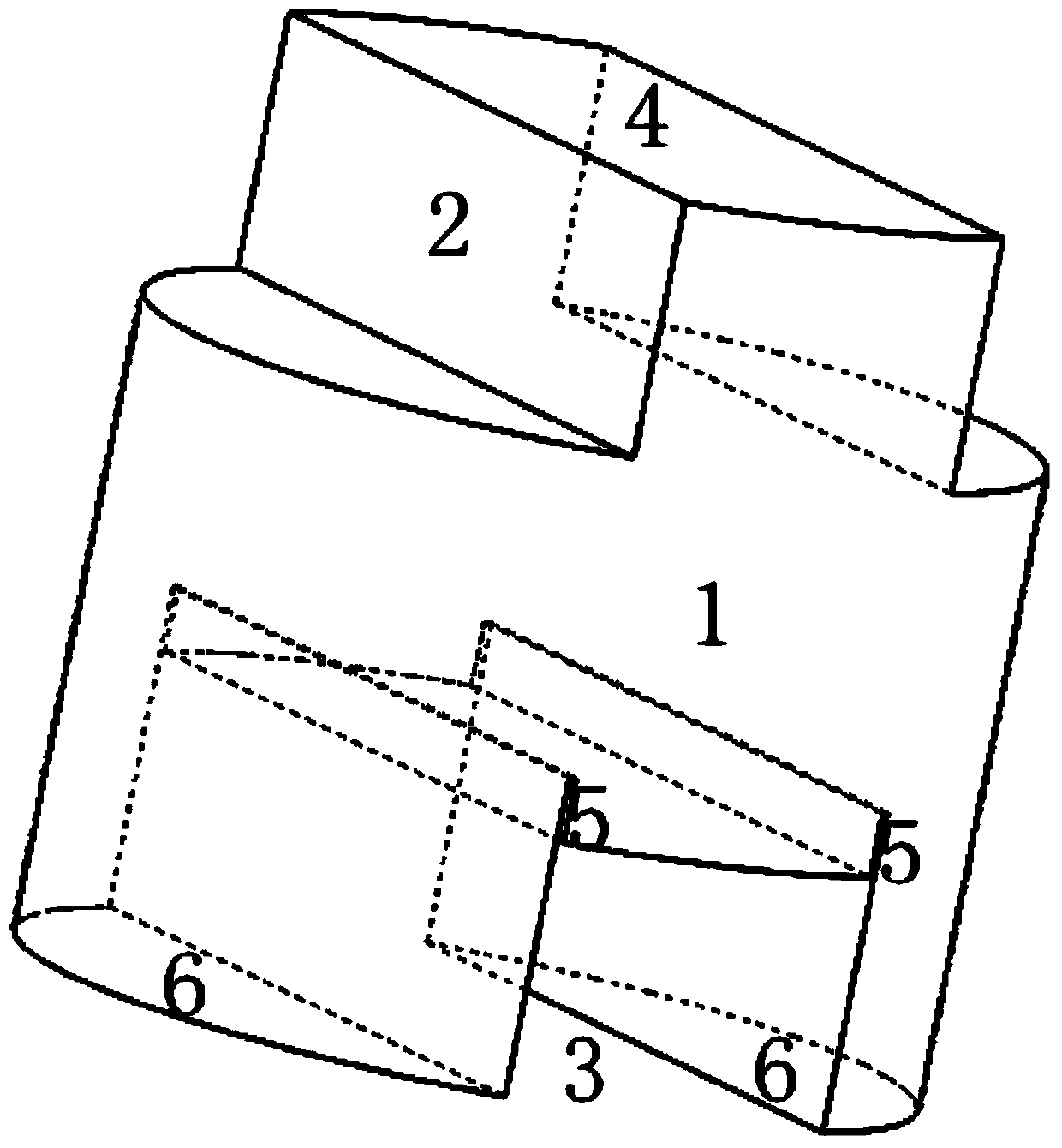

[0011] to combine figure 1 :

[0012] The invention discloses a shear specimen for studying type II fracture of viscoelastic materials under the condition of high strain rate. One end of a cylinder 1 is provided with a radially penetrating groove 3 , and the other end is provided with a radially penetrating boss 2 . The diameter and height of 1 are less than or equal to the diameter of the Hopkinson rod used in the experiment, the radially penetrating groove 3 is parallel to the radially penetrating boss 2, the end surface of the radially penetrating boss 2 is equal to the bottom surface area of the radially penetrating groove 3, And it is half of the cross-sectional area of the cylinder; both ends of the radial through groove 3 are provided with pre-cracks 5 along the direction of the side end surface of the radial through groove 3 .

[0013] The length of the pre-crack 5 in the axial direction of the test piece is less than 1 / 3 of the length of the test piece.

[0014]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com