High-precision measuring device for measuring joint type equipment member bar deformation

A measuring device, high-precision technology, applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effect of light weight, ensuring stability, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

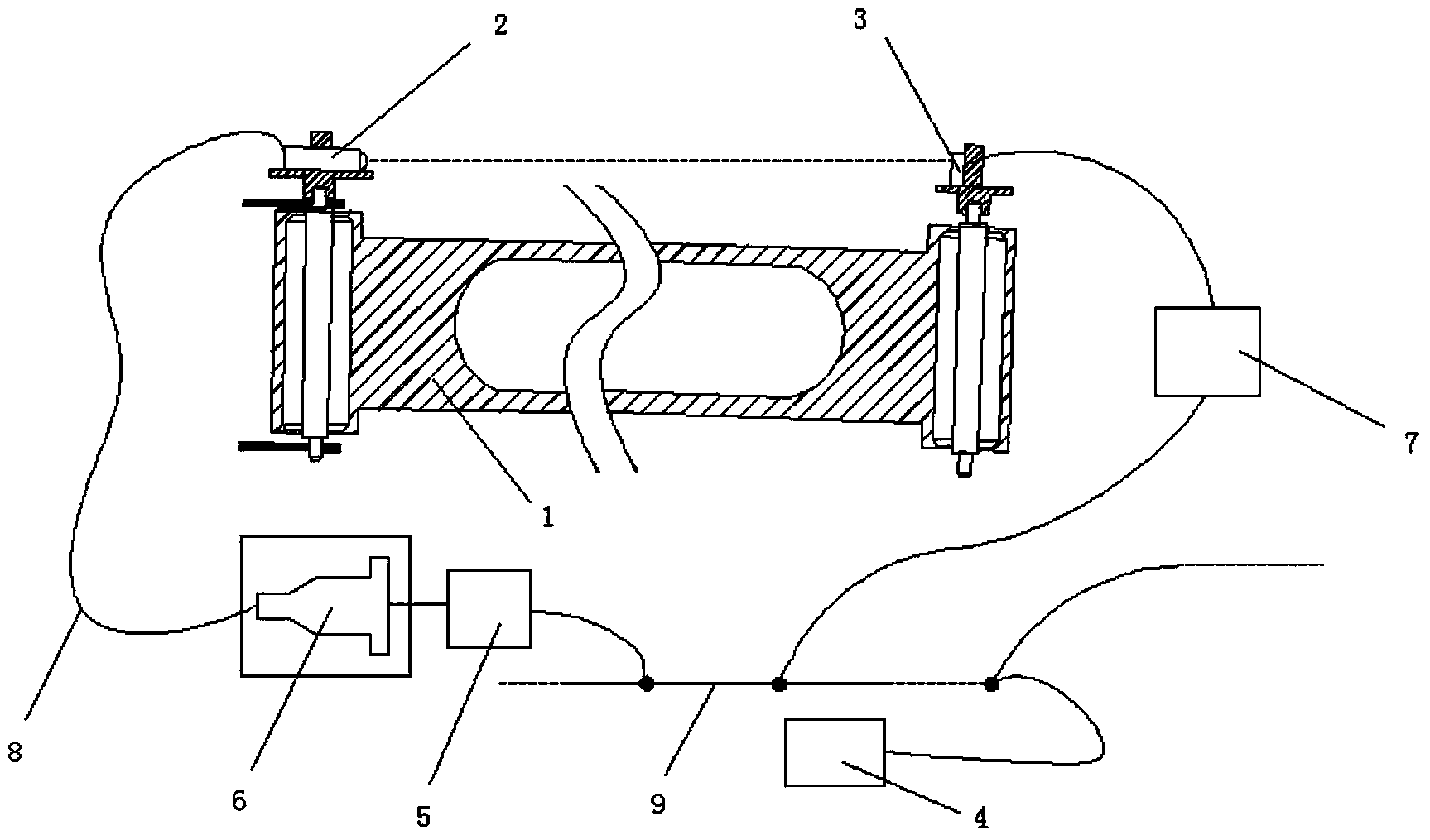

[0021] Such as figure 1 shown. A high-precision measuring device for measuring the deformation of a bar of joint equipment, comprising an optical head 2 arranged on the top of one end of a bar 1 of a parallel double-joint coordinate measuring machine, and an optical head 2 arranged on the top of the other end of the bar 1 of a parallel double-joint coordinate measuring machine The photosensitive surface 3, the optical head 2 is opposite to the photosensitive surface 3, and also includes a main control circuit 4, a laser drive unit 5, a laser diode 6, a signal detection circuit 7, and the signal detection circuit 7 and the laser drive unit 5 respectively adopt the IIC bus 9 The photosensitive surface 3 is connected to the input terminal of the signal detection circuit 7, the input terminal of the laser diode 6 is connected to the output terminal of the laser drive unit 5, and the output beam from the output terminal of the laser diode 6 is coupled to the optical head 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com