Operating room air supply ceiling

A technology for operating room and ceiling, applied in the direction of pipeline arrangement, etc., can solve the problems of heavy air supply ceiling, difficult installation, difficult maintenance and management, etc., and achieves the effect of good cleaning and dust removal, convenient filter replacement, and uniform air supply and airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

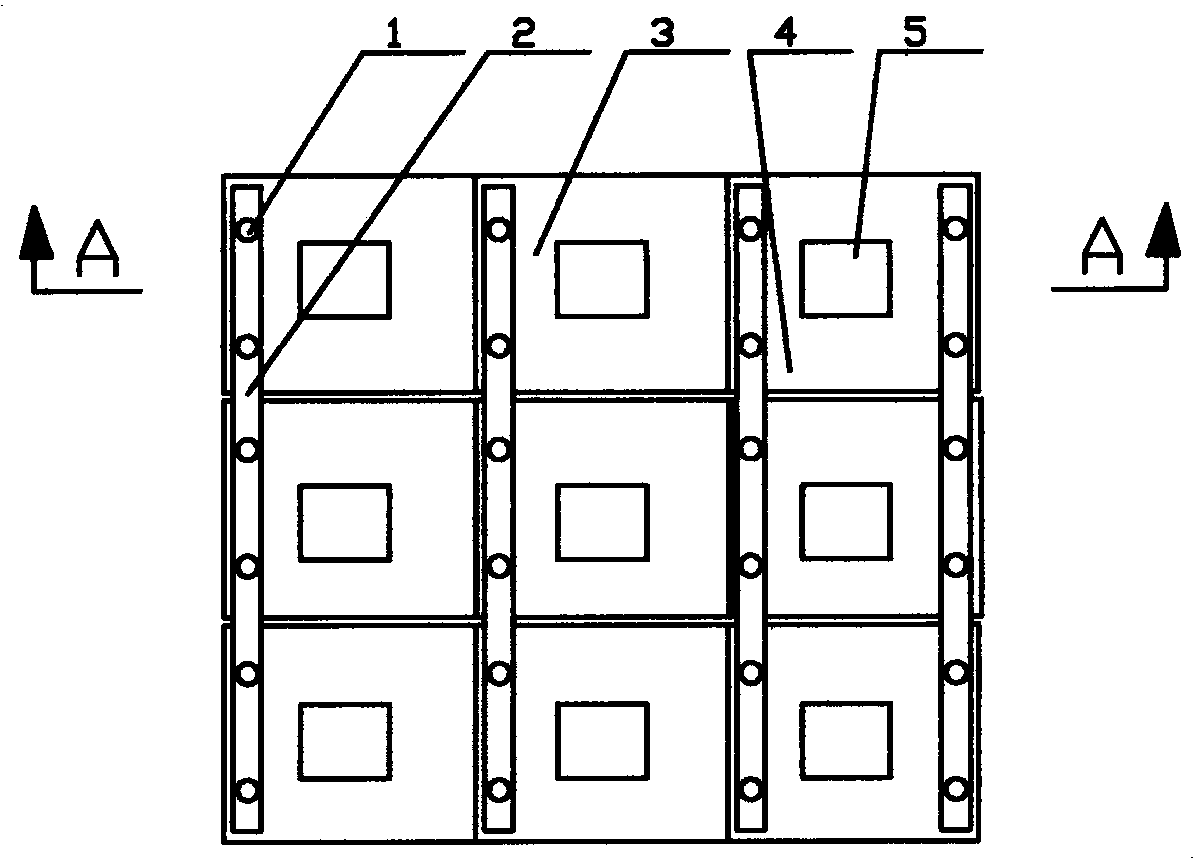

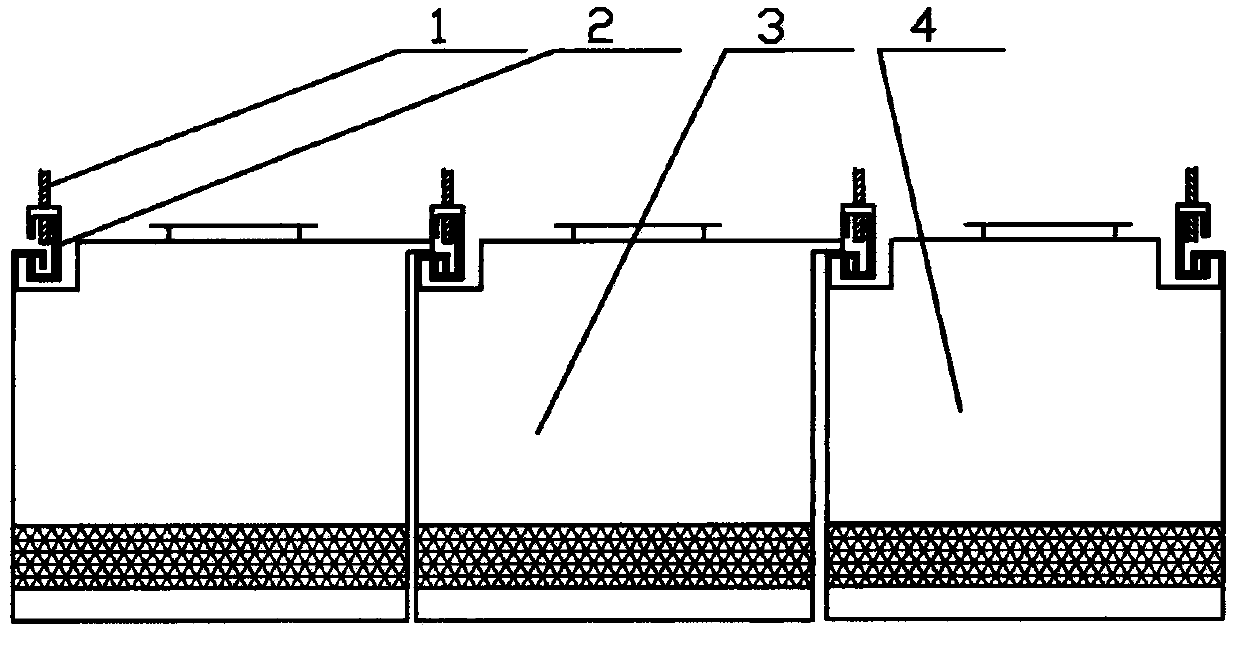

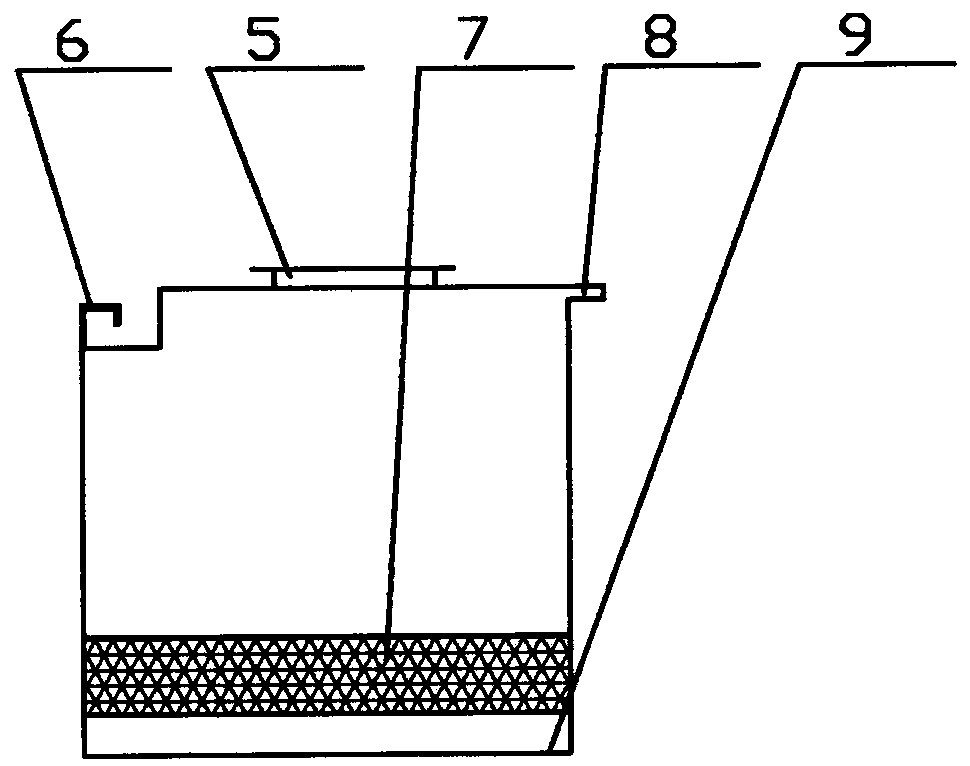

[0017] combine figure 1 , figure 2 , image 3 and Figure 4 The specific embodiment of the present invention is further described:

[0018] According to the technical solution provided by the present invention, an air-supply ceiling for an operating room includes a suspender 1, a suspension keel 2, a single-slot air-supply ceiling module 3, a double-slot air-supply ceiling module 4, an air duct flange 5, and a keel groove 6 , a high-efficiency filter 7, a protruding head 8, and an air outlet 9. The single-slot air-supply ceiling module 3 is made of a hollow cuboid made of a steel plate, and a high-efficiency Filter 7, the upper end of the single-slot air-supply ceiling module 3 has an air outlet and is equipped with an air duct flange 5, and the bottom of the single-slot air-supply ceiling module 3 is equipped with an air supply port 9, and the single-slot air supply ceiling module 3 is equipped with an air outlet 9. The upper left corner of the slotted air supply ceiling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com