Vortex drainage-type noise reduction drainage pipe and manufacturing method thereof

A manufacturing method and drainage pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of low cost performance, singleness, and high manufacturing cost of drain pipes, so as to reduce drainage noise, optimize material formula, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

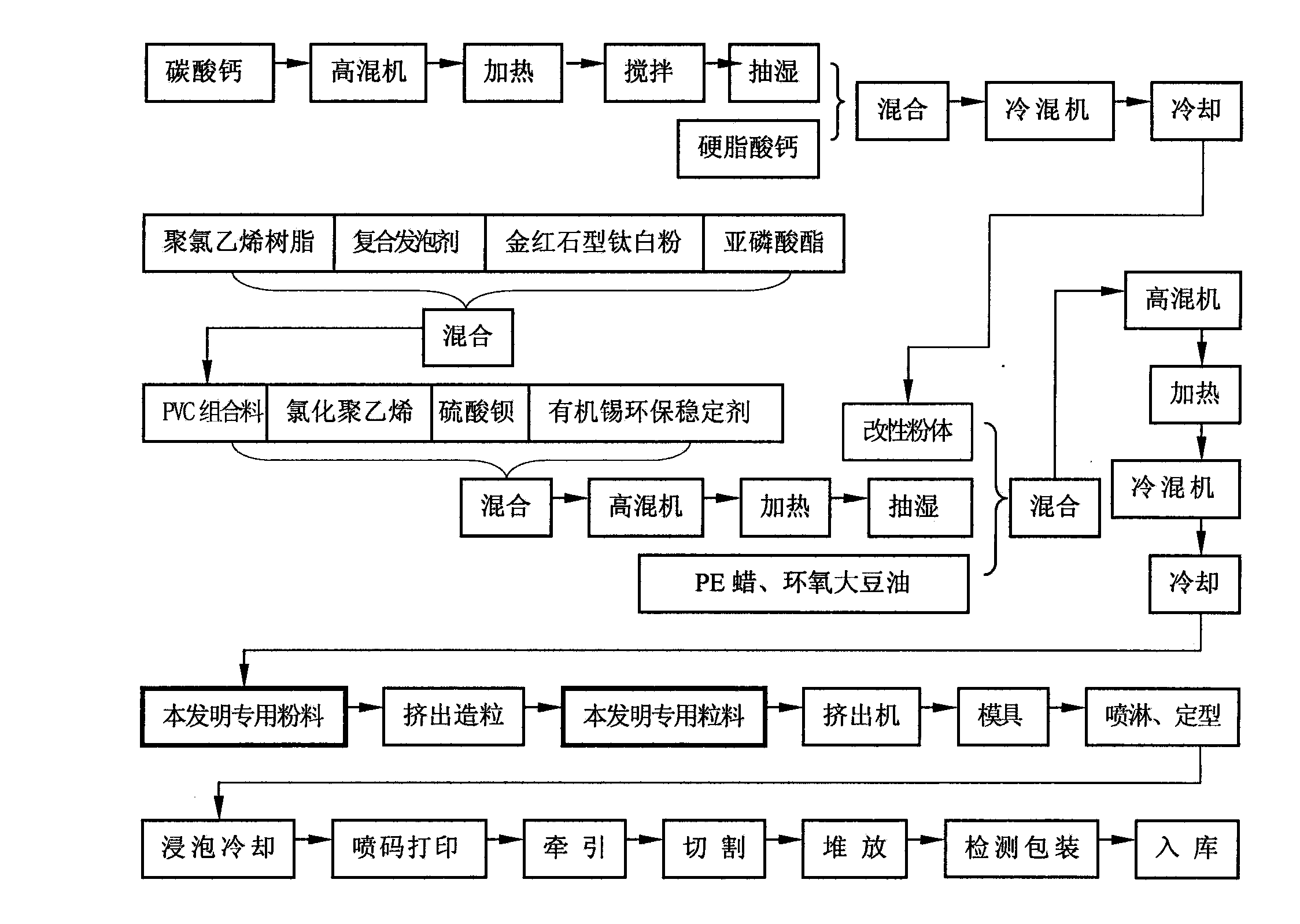

Method used

Image

Examples

Embodiment 1

[0041] Formula material composition is by weight:

[0042] 100 parts of polyvinyl chloride compound material, 40 parts of chlorinated polyethylene, 60 parts of barium sulfate (particle size is 10 μm), 4.5 parts of organic tin environmental stabilizer, 0.7 part of calcium stearate, 0.1 part of PE wax, 1.5 parts of epoxy soybean oil Parts, 90 parts of heavy calcium carbonate (1200 mesh).

[0043] A kind of vortex water discharge type noise-absorbing drainage pipe special granule prepared from the formula material of the above-mentioned embodiment 1 was put into an equal-diameter twin-screw extruder (90 machines) for extrusion. The speed of the host is 15±2rpm, the torque of the host is 40-50A, and its temperature parameters are:

[0044]

Embodiment 2

[0046] It is exactly the same as the process parameters and process equipment of the implementation case one, and the different formulas are composed by parts by weight:

[0047] 100 parts of polyvinyl chloride compound material, 45 parts of chlorinated polyethylene, 65 parts of barium sulfate (particle size is 10 μm), 4.5 parts of organic tin environmental stabilizer, 0.3 part of calcium stearate, 0.15 part of PE wax, 1.5 parts of epoxy soybean oil Parts, 80 parts of heavy calcium carbonate (1200 mesh).

Embodiment 3

[0049] It is exactly the same as the process parameters and process equipment of the implementation case one, and the different formulas are composed by parts by weight:

[0050] 100 parts of polyvinyl chloride composite material, 45 parts of chlorinated polyethylene, 70 parts of barium sulfate (10 μm particles), 5.0 parts of organic tin environmental stabilizer, 0.35 parts of calcium stearate, 0.08 parts of PE wax, 1.5 parts of epoxy soybean oil Parts, 90 parts of heavy calcium carbonate (1200 mesh).

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com