Adjusting valve capable of adjusting fire linearly

A linear, regulating valve technology, applied in the field of regulating valves, can solve the problems that ordinary plunger valves cannot achieve linear adjustment, cannot achieve linear flow control, and change the rotation angle of the valve body, so as to improve the effective rotation angle and adjustment accuracy, The effect of adjusting the gradient is uniform and reasonable, and the flow rate is linearly controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] Such as Figure 1-11 Shown is a preferred embodiment of the present invention.

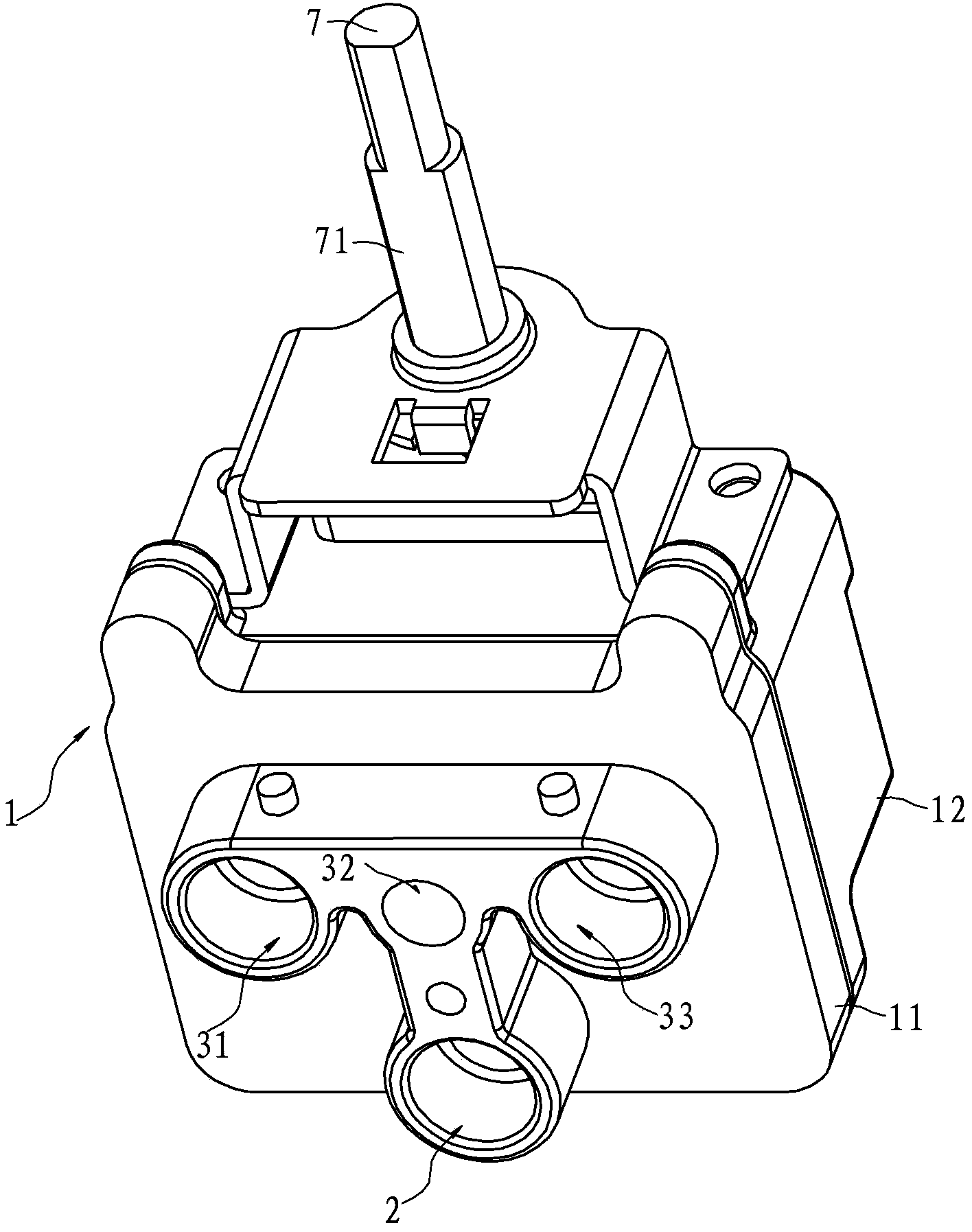

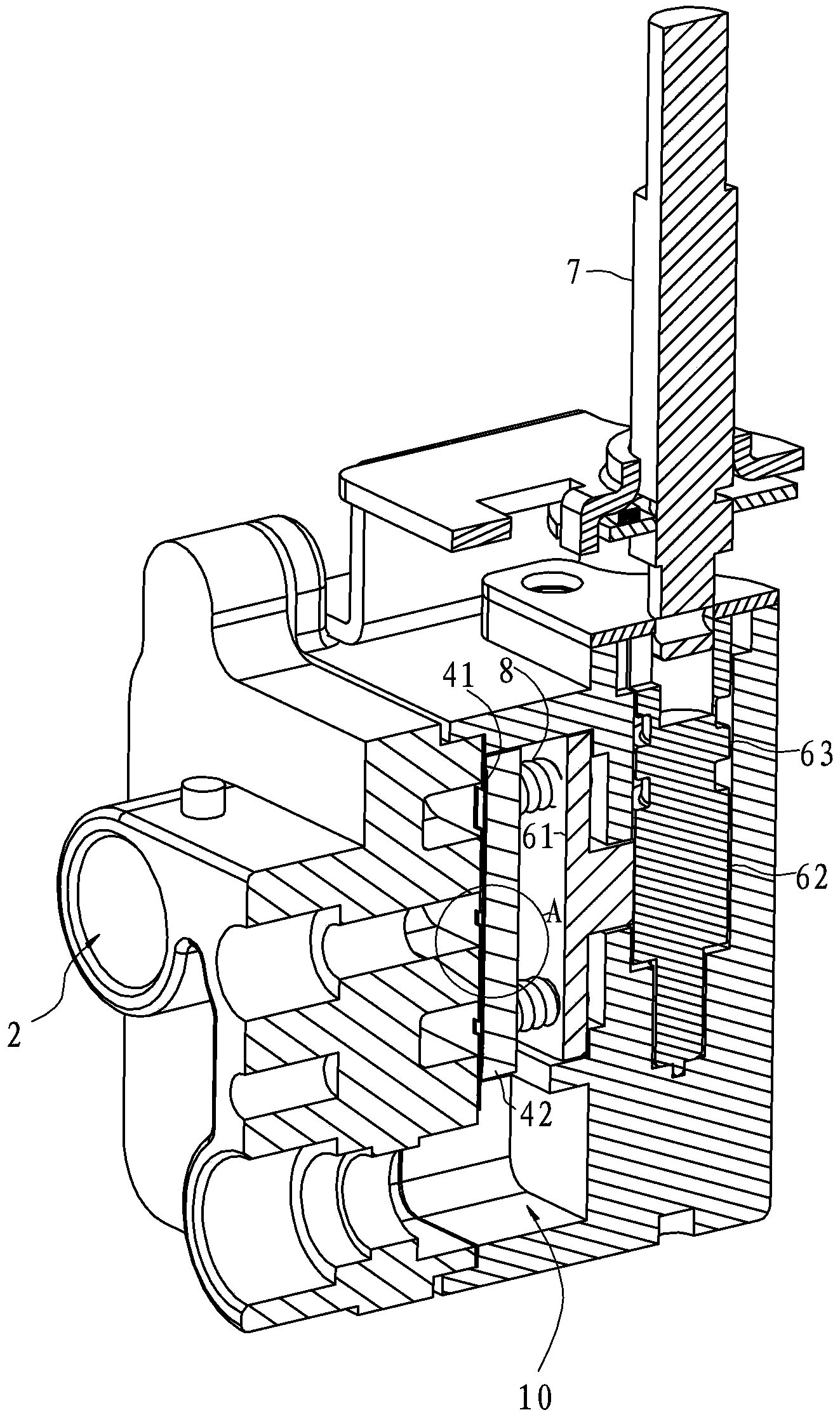

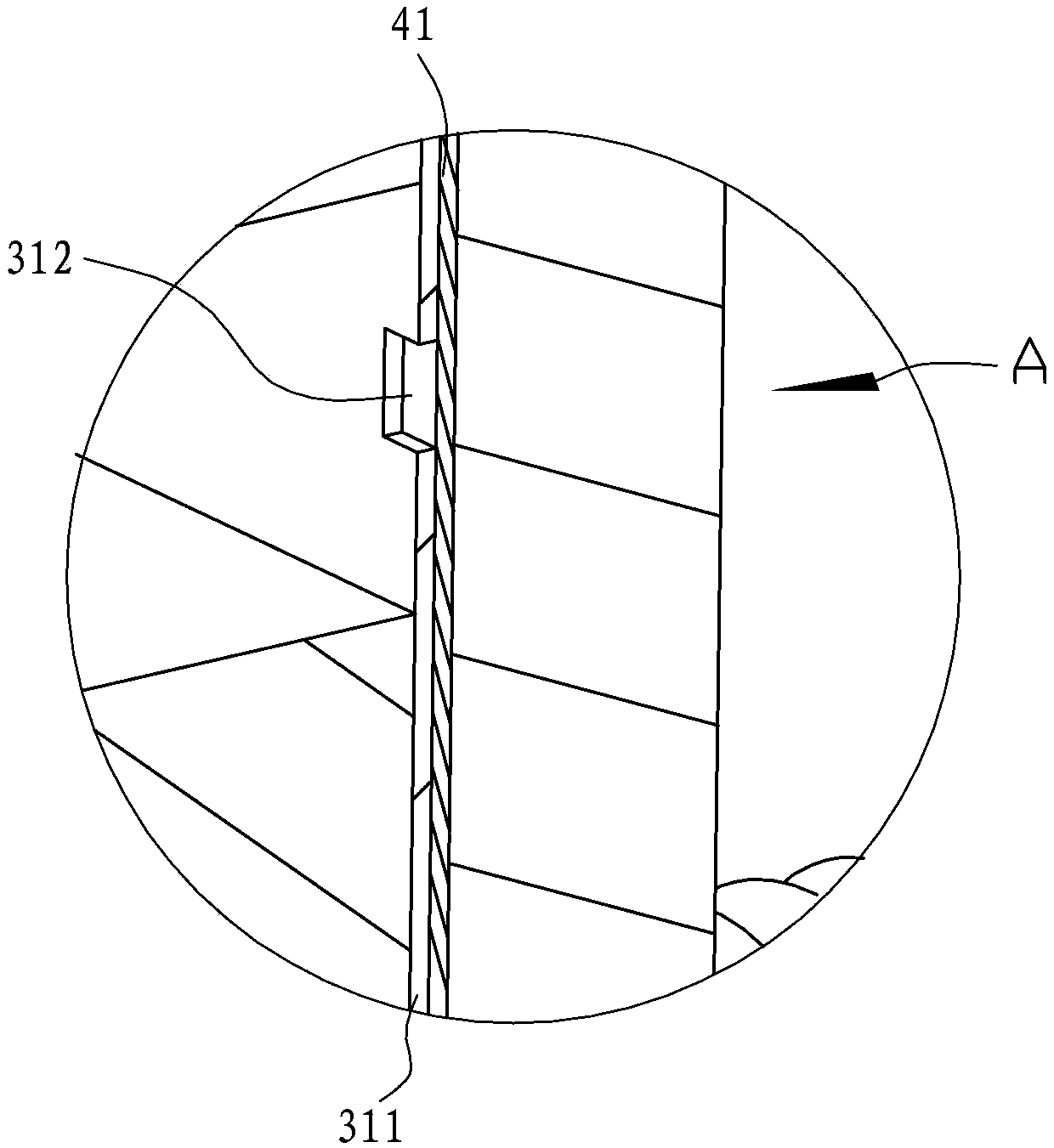

[0038] The regulating valve capable of linearly adjusting the firepower of the gas stove of the present invention includes a valve body 1, the valve body 1 is formed by connecting a front fixed cover 11 and a rear sealing cover 12, and a valve cavity 10 is formed inside it, and the front fixed cover 11 is provided with One air inlet 2 and three side-by-side air outlets 3, this structural arrangement is conducive to the rational layout of the inlet and outlet air pipes of the cooker of the present invention on the chassis, wherein the air inlet 2 connected with the gas source and the valve cavity 10 connected, all the outlets 31 of the air outlets 3 on the inner wall of the valve cavity are located on the same plane, in order to further effectively reduce t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com