Method for improving room-temperature plasticity of amorphous alloy

An amorphous alloy and amorphous technology, which is applied in the field of improving room temperature plasticity of amorphous alloys, can solve problems such as difficult plasticity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] The first is the preparation of the electroplating solution: the ratio of the electroplating solution is

[0021] Nickel sulfate heptahydrate 280g / L

[0022] Nickel chloride hexahydrate 40g / L

[0023] Boric acid 40g / L

[0024] The specific operation method is: add an appropriate amount of high-purity water into the beaker, and weigh the quality of the medicine with a balance according to the proportion. Since boric acid is not easy to dissolve, first add boric acid into the beaker, and heat it with water at 65°C in a water bath. Stir continuously until fully dissolved. Then add nickel sulfate and nickel chloride in turn, stir until completely dissolved, and finally continue to add high-purity water to the beaker to the specified amount. The prepared electroplating solution is dark green.

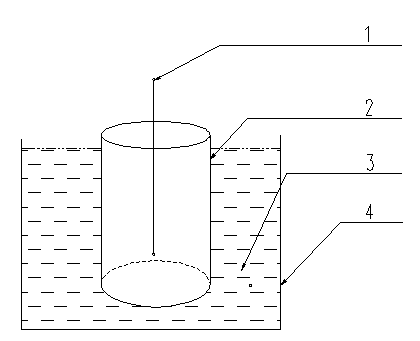

[0025] Then there is the process of electroplating, which is an electrochemical process and also a redox process. The basic process of electroplating is to immerse the part in a...

Embodiment approach 2

[0038] The heating temperature of the water bath is 60°C when preparing the electroplating solution, the heating temperature of the water bath is 35°C during electroplating, and the electroplating time is 5 hours. Others are the same as Embodiment 1.

Embodiment approach 3

[0040] The workpiece to be plated is a plate of 65*5*1.5mm, the power supply voltage is 1.20V, the heating temperature of the water bath is 70°C when preparing the electroplating solution, the heating temperature of the water bath is 45°C during electroplating, and the electroplating time is 3 hours. Others are the same as Embodiment 1 .

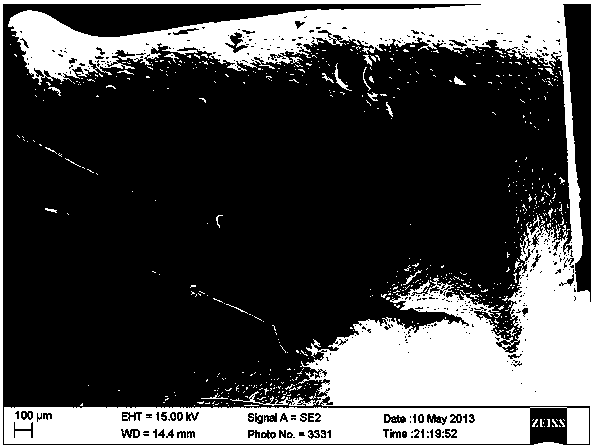

[0041] In this method, the thickness of the plating layer can be adjusted by adjusting the voltage and changing the size of the current to adjust the speed of electroplating and changing the time of electroplating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com