Slag gasifier for pressurized fixed bed

A technology of slag gasification and pressurized gasification, which is applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of low effective gas content, high gasifier outlet temperature, and many problems of chilling ring, etc., to achieve effective The effects of high gas content, high comprehensive cost performance, and strong adaptability to coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Embodiments of the present invention will now be described more fully with reference to the accompanying drawings. The following description is merely exemplary in nature and does not limit the invention, its application or uses.

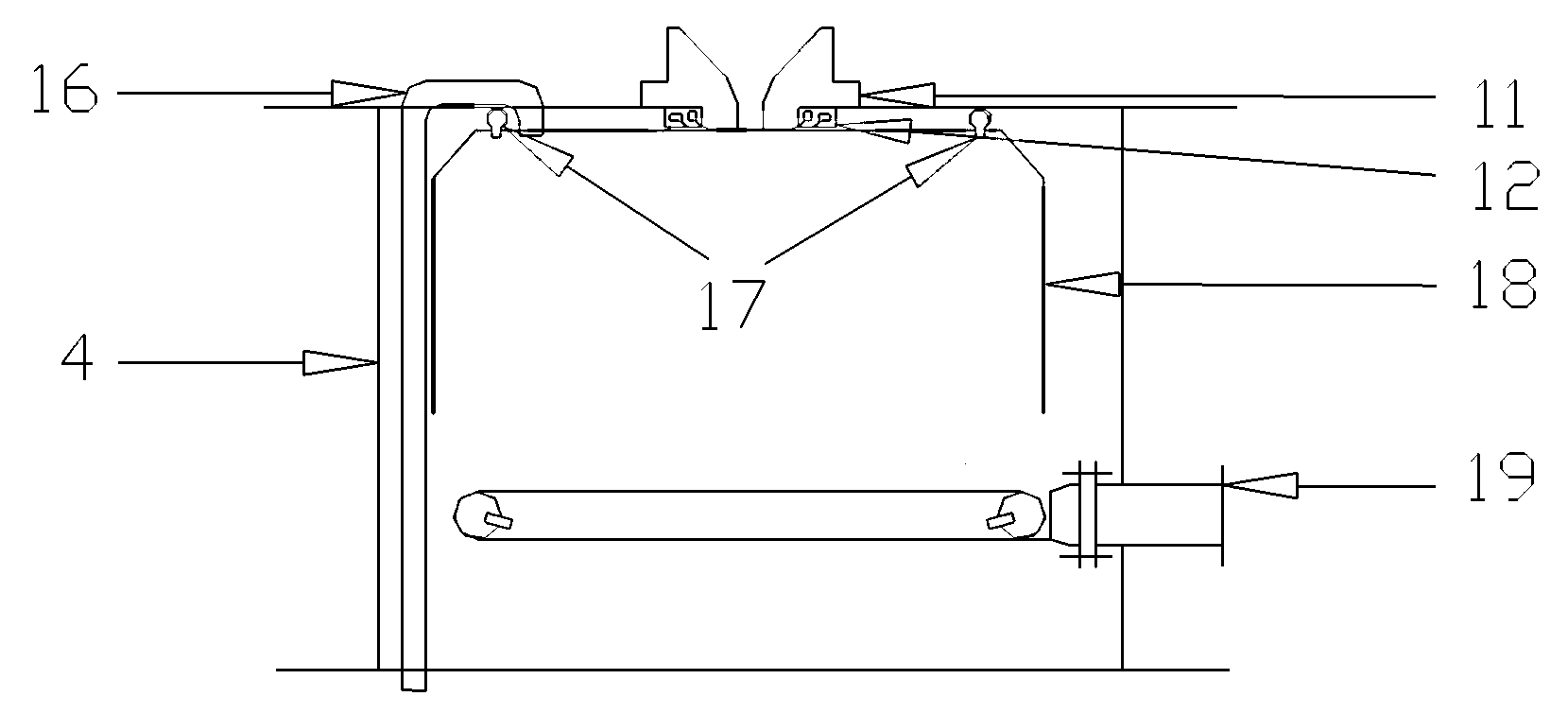

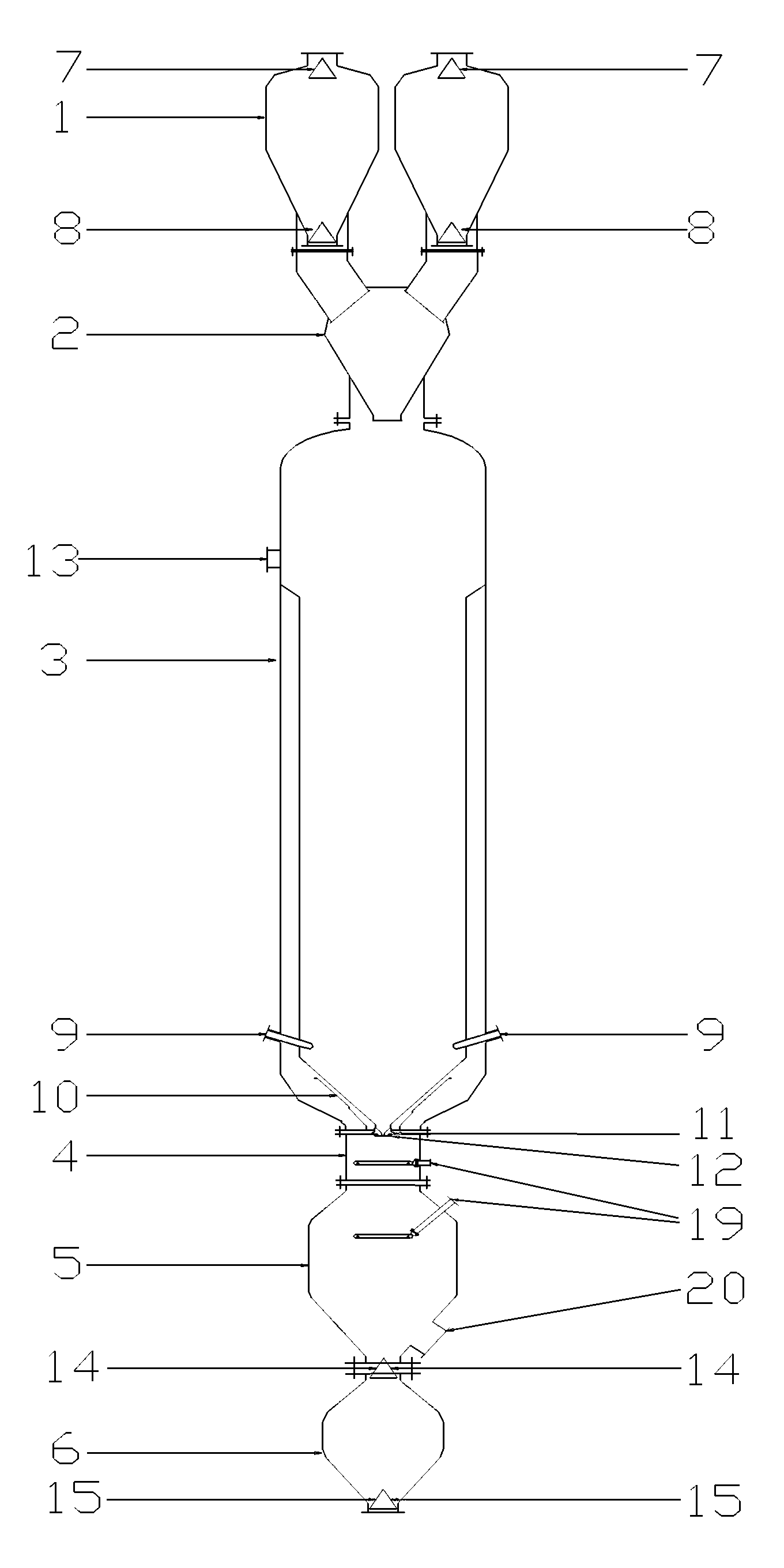

[0059] Such as figure 1 As shown, the pressurized fixed-bed slag gasifier according to the embodiment of the present invention includes a coal lock 1 (two coal locks are shown in the figure), a transition chamber 2, a pressurized gasification vessel 3, a connecting joint 4, Chill chamber 5 and slag lock 6. The coal lock 1 is a storage container located on the upper part of the transition bin 2 for intermittently taking coal from the coal bunker (not shown in the figure) and adding coal to the pressurized gasification container 3 . The transition bin 2 is a "Y"-shaped channel located between the coal lock 1 and the pressurized gasification vessel 3, which promotes the coal in the coal lock 1 to enter the pressurized gasification vessel 3 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com