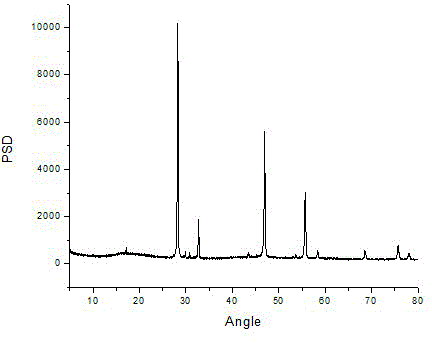

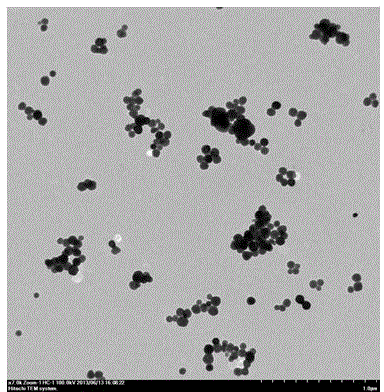

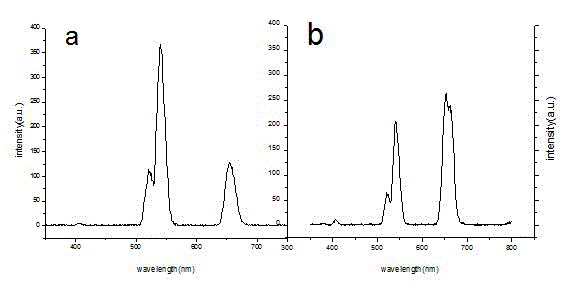

Preparation method of water-soluble red-green light tunable rare-earth doped up-conversion nano-material

A nano-material, water-soluble technology, applied in the direction of luminescent materials, material excitation analysis, chemical instruments and methods, etc., can solve the problems of limited application, large particle size, complex operation, etc., easy to achieve surface functionalization, and low synthesis temperature , the effect of fluorescence enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Yttrium oxide Y 2 0 3 (0.4mmol, Mr=224.81), Ytterbium oxide Yb 2 0 3 (0.09mmol, Mr=394.08), Erbium oxide 2 O 3 (0.01mmol, Mr=382.52), that is Y, 0.8mmol, Yb, 0.18mol, Er, 0.02mmol, the ratio of the amount of ytterbium to erbium Yb / Er=9 / 1, Y+Yb+Er=1mmol, F / Y+Yb+Er=4 / 1, 0.15g polyethyleneimine PEI, solvent: 15ml ethylene glycol, temperature 200oC.

[0038] First, add 0.0903g yttrium oxide Y 2 0 3 , 0.0355g ytterbium oxide Yb 2 0 3 ,0.0038g Erbium oxide Er 2 0 3 (The ratio of the amount of ytterbium to erbium substance Yb / Er=9 / 1) Put into a 50ml beaker, add 1.5ml concentrated nitric acid, 4ml high purity water, in a fume hood, adjust the temperature of the heating mantle to 100oC, and the solid powder after 5min It will dissolve and evaporate to dryness. When placed in the sun, a crystal film can be seen at the bottom of the beaker. Add 4ml of high-purity water and evaporate to dryness.

[0039] Secondly, weigh 0.1680g sodium fluoride NaF (F / Y+Yb+Er=4 / 1), add 9ml ethylene...

Embodiment 2

[0044] Yttrium oxide Y 2 0 3 (0.4mmol, Mr=224.81), Ytterbium oxide Yb 2 0 3 (0.09mmol, Mr=394.08), Erbium oxide 2 O 3 (0.01mmol, Mr=382.52), that is Y, 0.8mmol, Yb, 0.18mol, Er, 0.02mmol, the ratio of the amount of ytterbium to erbium Yb / Er=9 / 1, Y+Yb+Er=1mmol, F / Y+Yb+Er=4 / 1, 0.15g polyethyleneimine PEI, solvent: 12ml ethylene glycol + 3ml high purity water, temperature 180oC.

[0045] First, add 0.0903g yttrium oxide Y 2 0 3 , 0.0355g ytterbium oxide Yb 2 0 3 ,0.0038g Erbium oxide Er 2 0 3 (The ratio of the amount of ytterbium to erbium substance Yb / Er=9 / 1) Put into a 50ml beaker, add 2ml concentrated nitric acid, 4ml high purity water, in a fume hood, adjust the temperature of the electric heating mantle to 100oC, the solid powder will be It will dissolve and evaporate to dryness. A crystal film can be seen at the bottom of the beaker in the sun. Add 4ml of high-purity water and evaporate to dryness.

[0046] Secondly, weigh 0.1680g (F / Y+Yb+Er=4 / 1) NaF, add 9ml ethylene glyc...

Embodiment 3

[0050] Yttrium oxide Y 2 0 3 (0.4mmol, Mr=224.81), Ytterbium oxide Yb 2 0 3 (0.09mmol, Mr=394.08), Erbium oxide 2 O 3 (0.01mmol, Mr=382.52), that is Y, 0.8mmol, Yb, 0.18mol, Er, 0.02mmol, the ratio of the amount of ytterbium to erbium Yb / Er=9 / 1, Y+Yb+Er=1mmol, F / Y+Yb+Er=4 / 1, 0.15g polyethyleneimine PEI, solvent: 6ml ethylene glycol + 9ml high purity water, temperature 160oC.

[0051] First, add 0.0903g yttrium oxide Y 2 0 3 , 0.0355g ytterbium oxide Yb 2 0 3 ,0.0038g Erbium oxide Er 2 0 3 (The ratio of the amount of ytterbium to erbium substance Yb / Er=9 / 1) Put it in a 50ml beaker, add 3ml concentrated nitric acid, 4ml high purity water, in a fume hood, adjust the temperature of the electric heating mantle to 100oC, the solid powder will be It will dissolve and evaporate to dryness. When placed in the sun, a crystal film can be seen at the bottom of the beaker. Add 4ml of high-purity water and evaporate to dryness.

[0052] Secondly, weigh 0.1680g (F / Y+Yb+Er=4 / 1) sodium fluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com