Method for preparing adsorption resin through using (methyl)acrylic acid production wastewater as raw material

A technology for methacrylic acid and wastewater production, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment, etc., to achieve the effects of simple process, COD reduction, and a wide range of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

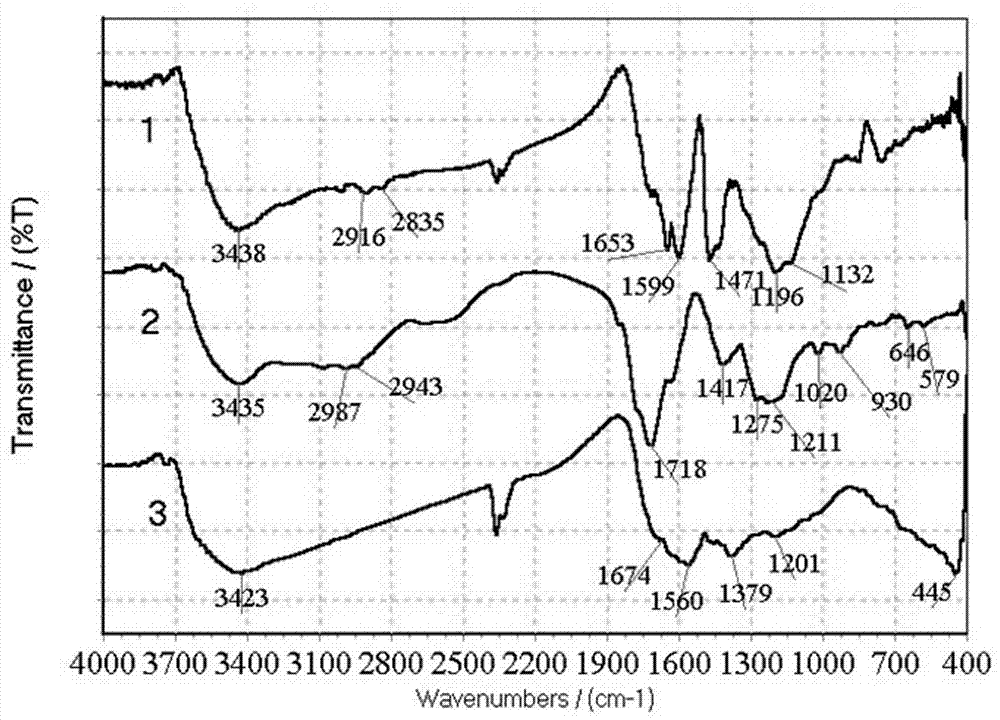

Image

Examples

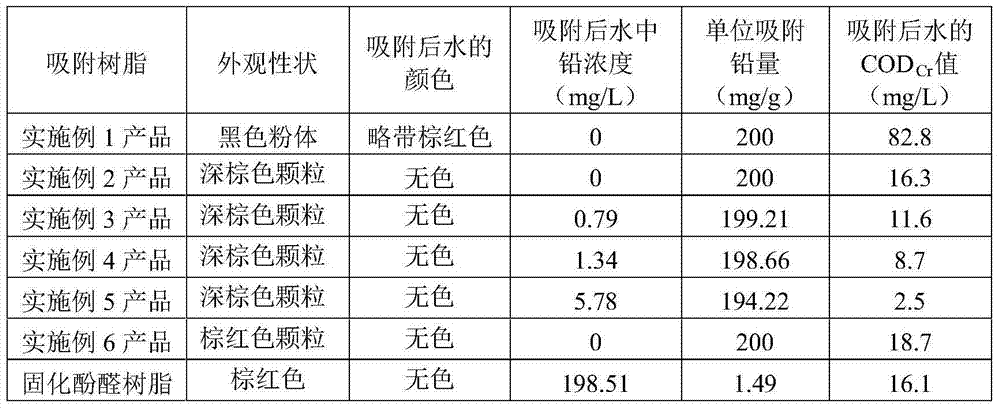

Embodiment 1

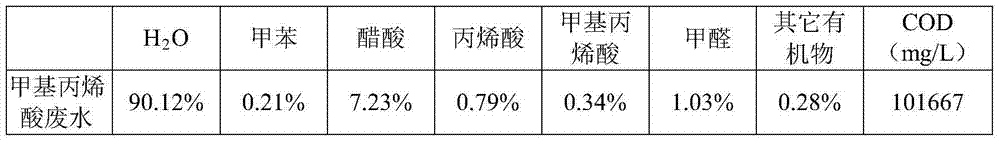

[0026] The wastewater used in this example is methacrylic acid wastewater, and its composition is shown in Table 1; the method of this example is as follows: directly enter the evaporator for heating and evaporating the wastewater, and after the steam is condensed, it can be neutralized with alkali to recover sodium acetate. When the volume of the remaining waste liquid after evaporation is about 5% of the volume of the original waste water, the material is discharged to obtain a viscous mixed polymer, which is then dried. Weigh 50g of mixed polymer, add 25g of phenolic resin (based on resin mass), stir and mix evenly, glue and solidify at 150°C for 120min, cool to room temperature in a desiccator, crush, sieve, and take 80-200 mesh The parts in between were soaked in 1mol / L sodium hydroxide solution for 12 hours, washed with water until neutral, and dried at 105°C. The heavy metal adsorption resin can be obtained.

Embodiment 2

[0028] The wastewater used in this example is methacrylic acid wastewater, and its composition is shown in Table 1; the method of this example is as follows: directly enter the evaporator for heating and evaporating the wastewater, and after the steam is condensed, it can be neutralized with alkali to recover sodium acetate. When the volume of the remaining waste liquid after evaporation is about 5% of the volume of the original waste water, the material is discharged to obtain a viscous mixed polymer, which is then dried. Weigh 50g of the mixed polymer, add 50g of phenolic resin (calculated by resin mass), stir and mix evenly, glue and solidify at 150°C for 120min, cool to room temperature in a desiccator, crush, sieve, and take 80-200 mesh The parts in between were soaked in 1mol / L sodium hydroxide solution for 12 hours, washed with water until neutral, and dried at 105°C. That is, the heavy metal adsorption resin is obtained.

Embodiment 3

[0030] The waste water used in this embodiment is methacrylic acid waste water, and its composition is shown in Table 1; the method of this embodiment is as follows: directly enter the evaporator for heating and evaporating the waste water, and after the steam is condensed, it can be neutralized with alkali to recover sodium acetate. When the volume of the remaining waste liquid after evaporation is about 5% of the volume of the original waste water, the material is discharged to obtain a viscous mixed polymer, which is then dried. Weigh 50g of mixed polymer, add 60g of phenolic resin (based on resin mass), stir and mix evenly, glue and solidify at 150°C for 120min, cool to room temperature in a desiccator, crush, sieve, and take 80-200 mesh The parts in between were soaked in 1mol / L sodium hydroxide solution for 12 hours, washed with water until neutral, and dried at 105°C. That is, the heavy metal adsorption resin is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com