Method for preparation of rime-like titanate by taking organic matters in methacrylic acid wastewater as template agent

A technology of methacrylic acid and template agent, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve problems such as no reports, and achieve the effects of simple process, wide range of heavy metals, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

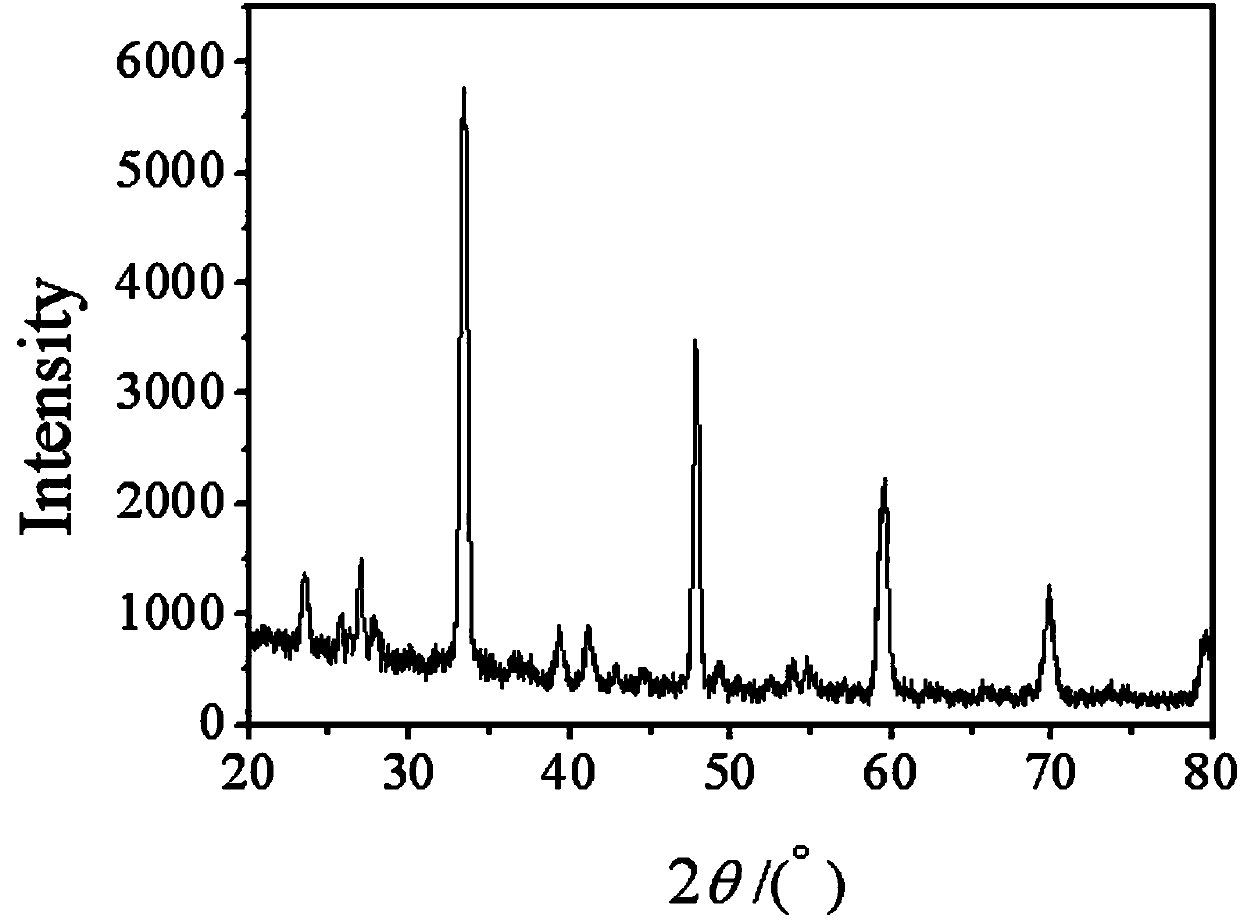

Image

Examples

Embodiment 1

[0025] The waste water that present embodiment uses is methacrylic acid waste water, and composition is shown in Table 1; Present embodiment method is as follows:

[0026] Take 10L of waste water, heat and evaporate the water and acetic acid therein, and recover sodium acetate. When the remaining amount of waste water is about 500mL, the material is discharged to obtain the complex template agent. Weigh 0.2 mol of calcium nitrate, dissolve it in 100 g of complexing template agent in a water bath at 60°C under stirring condition, keep stirring for 1 hour, and disperse evenly to obtain a jelly. Keep the water bath at 60°C, and add 0.2 mol of tetra-n-butyl titanate dropwise into the calcium-containing jelly under continuous vigorous stirring. After continuing to stir for 1 hour, put the jelly in an oven and dry it at 105°C to obtain a calcium titanate gel. Calcinate it at 750°C for 8 hours in the air atmosphere, and cool it down to room temperature naturally in the furnace to ob...

Embodiment 2

[0028] Weigh 0.02 mol of calcium nitrate, and dissolve it in 100 g of the complexing template agent obtained in Example 1 in a water bath at 60° C. under stirring conditions, continue stirring for 1 hour, and disperse evenly to obtain a jelly. Keep the water bath at 60°C, and add 0.02 mol of tetra-n-butyl titanate dropwise into the calcium-containing jelly under continuous vigorous stirring. After continuing to stir for 1 hour, put the jelly in an oven and dry it at 105°C to obtain a calcium titanate gel. Calcinate it at 750°C for 8 hours in the air atmosphere, and cool it down to room temperature naturally in the furnace to obtain rime-like nano-calcium titanate. Adsorbent.

Embodiment 3

[0030] Weigh 0.2 mol of calcium nitrate, and dissolve it in 100 g of the complexing template agent obtained in Example 1 in a water bath at 60° C. under stirring conditions, continue stirring for 1 hour, and disperse evenly to obtain a jelly. Keep the water bath at 60°C, and add 0.2 mol of tetra-n-butyl titanate dropwise into the calcium-containing jelly under continuous vigorous stirring. After continuing to stir for 1 hour, put the jelly in an oven and dry it at 105°C to obtain a calcium titanate gel. Calcinate it at 850°C for 8 hours in an air atmosphere, and cool it down to room temperature naturally in the furnace to obtain a rime-like nano-calcium titanate. Adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com