Method for purifying and separating chlorosilane from polysilicon tail gas

A technology for purification and separation of chlorosilanes, applied in the direction of halogenated silanes, halogenated silicon compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

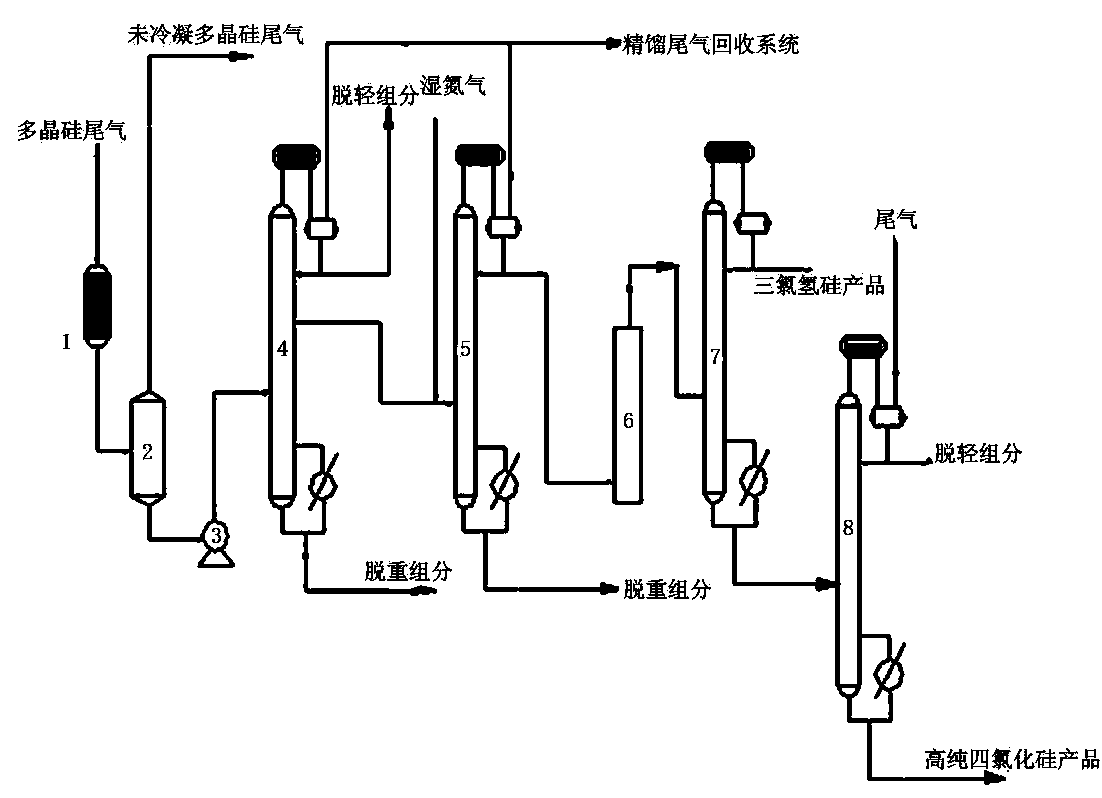

[0021] A method for purifying and separating chlorosilanes in polysilicon tail gas, comprising the steps of:

[0022] Step 1. Tail gas from reduction reaction, hydrogenation reaction, and synthesis reaction in polysilicon production contains hydrogen, trichlorosilane, silicon tetrachloride, dichlorodihydrosilane, and hydrogen chloride. The tail gas enters the inlet of polysilicon tail gas cooling device 1 and is circulated The water is cooled, and the gas-liquid mixture enters the gas-liquid separation tank 2.

[0023] Step 2, the tail gas containing chlorosilane enters the gas-liquid separation tank 2, and the liquid chlorosilane is separated from the uncondensed tail gas, and the uncondensed tail gas is output from the upper outlet of the gas-liquid separation tank 2;

[0024] Step 3: The chlorosilane output from the outlet of the lower part of the gas-liquid separation tank 2 is pressed into the rectification tower A4 through the chlorosilane delivery pump 3, the tower kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com