Method for preparing graphene based non-metallic oxygen reduction catalyst

A graphene-based, non-metallic technology, applied in graphene, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the limitations of fuel cells, metal-air battery commercialization, poor cycle stability of Pt-based catalysts, obstacles Battery performance improvement and other issues, to achieve the effects of aerobic reduction catalytic performance and stability, good oxygen reduction performance, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

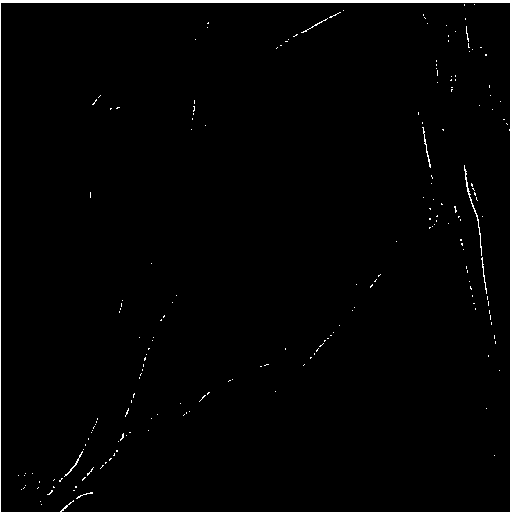

[0039] Graphene oxide was prepared according to Hummer's (Hummers, W.S. & Offeman, R.E. PREPARATION OF GRAPHITIC OXIDE. Journal of the American Chemical Society 80, 1339-1339 (1958)) method and formulated into a solution with a concentration of about 0.8 mg / ml. Take 10ml of the above solution and put it into a jar, place the jar in a water bath and stir vigorously with a magnetic stirrer, keeping the temperature at 90°C. After 2h, 50ml of sodium sulfide solution with a concentration of 20mg / ml was added dropwise, and stirring was continued at 90°C for 24h. The above solution is centrifuged, washed and dried to obtain the catalyst. The catalyst is in the form of flakes (see image 3 ), containing sulfur element, the content of sulfur element is 2.5mol%. Depend on Figure 5 It can be seen that there is an obvious oxygen reduction peak at about 0.45V, indicating that the prepared catalyst has oxygen reduction performance; Image 6It can be seen that after 1000 cycles, the pea...

Embodiment 2

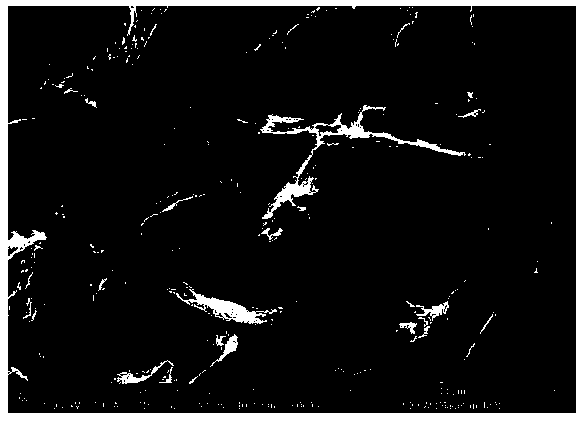

[0041] Graphene oxide was prepared according to the method of hummer's (Hummers, W.S. & Offeman, R.E. PREPARATION OF GRAPHITIC OXIDE. Journal of the American Chemical Society 80, 1339-1339 (1958)) and formulated into a solution with a concentration of about 0.8 mg / ml. Take 10ml of the above solution and put it into a jar, place the jar in a water bath, and keep the temperature at 90°C. After 2h, 50ml of sodium sulfide solution with a concentration of 50mg / ml was added dropwise, and stirring was continued at 90°C for 24h. The above solution is centrifuged, washed and dried to obtain the catalyst. The catalyst is in block form (see Figure 4 ), containing sulfur element, the content of sulfur element is 1.2mol%. Depend on Figure 7 It can be seen that there is an obvious oxygen reduction peak at about 0.45V, indicating that the prepared catalyst has oxygen reduction performance; Figure 8 It can be seen that after 1000 cycles, the peak intensity and peak position of the oxyg...

Embodiment 3

[0043] Graphene oxide was prepared according to the method of hummer's (Hummers, W.S. & Offeman, R.E. PREPARATION OF GRAPHITIC OXIDE. Journal of the American Chemical Society 80, 1339-1339 (1958)) and formulated into a solution with a concentration of about 0.8 mg / ml. Take 10ml of the above solution and put it into a jar, place the jar in a water bath and stir vigorously with a magnetic stirrer, keeping the temperature at 70°C. After 2h, 20ml of 45wt% ammonium sulfide solution was added dropwise, and stirring was continued at 70°C for 24h. The above solution is centrifuged, washed and dried to obtain the catalyst. The catalyst is flake-shaped and contains sulfur and nitrogen elements. The content of sulfur element is 1.5mol%, and the content of nitrogen element is 2.1mol%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com