Manufacturing method for degradable environment-friendly packing material and application thereof

A packaging material and production method technology, applied in the field of article packaging, can solve the problems of polluting land and water sources, consuming large oil energy, increasing land pressure, etc., and achieving the effects of good bending, rich raw materials and good hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

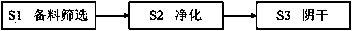

[0022] Such as figure 1 Shown, the preparation method of a kind of degradable environment-friendly packing material provided by the present invention, it comprises the following steps:

[0023] S1. Preparing and screening: picking natural plant leaves such as melon leaves, banana leaves, taro leaves or lotus leaves with complete leaf shapes;

[0024] S2. Purification: Clean or wipe the screened leaves to remove impurities such as soil or dirt on the leaves of natural plants;

[0025] S3. Drying in the shade: Put the purified natural plant leaves in the sun for 1.5-3 hours in an environment with a temperature of 0-35°C for 1.5-3 hours, so that the leaves have certain firmness, water resistance, bendability and good hand feeling, so as to avoid The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com