Variable radius arc frame type preheating device

A preheating device and frame-type technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of reducing the cooling speed of metal in the heat-affected zone, achieve automatic correction of preheating temperature, convenient and safe operation , the effect of preventing the device from being stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

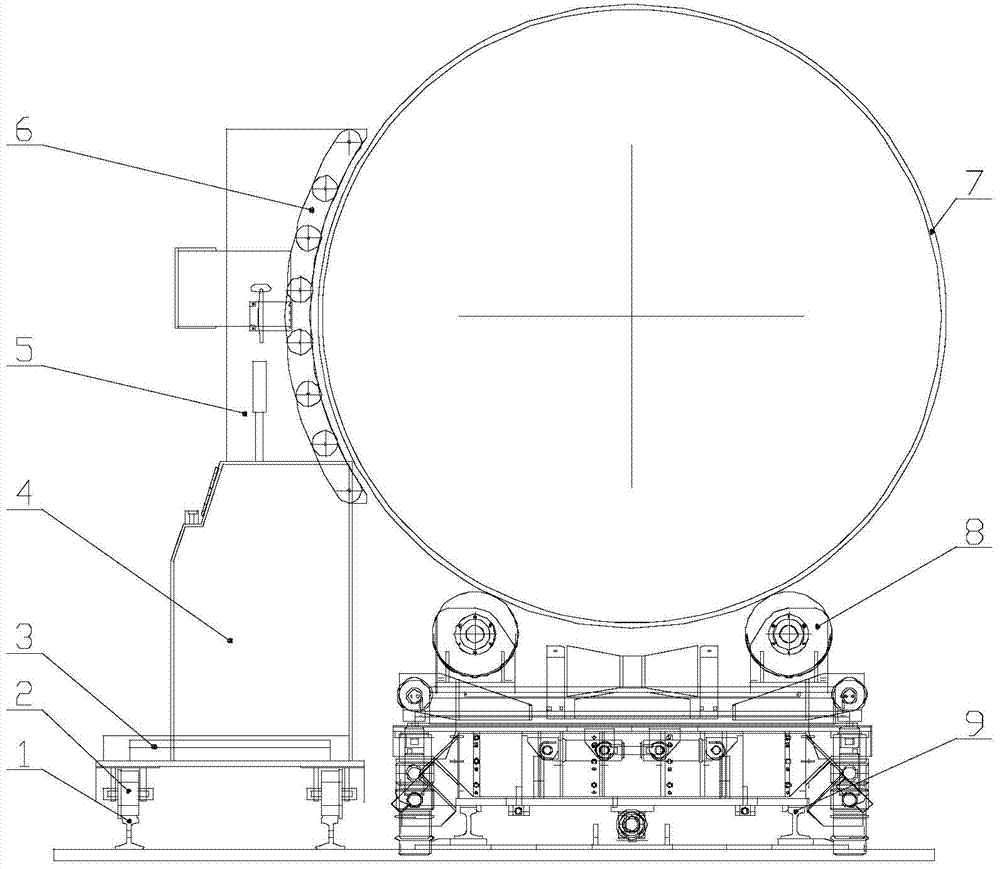

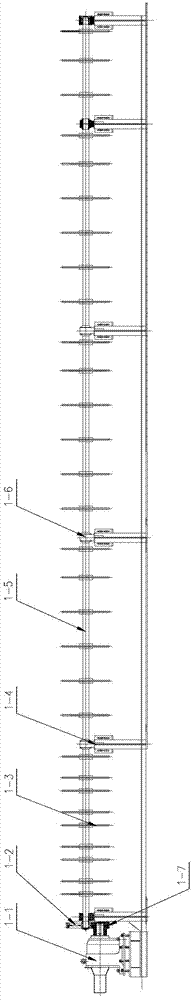

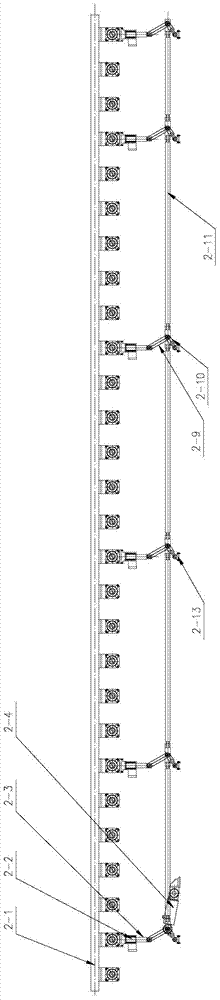

[0014] A variable radius arc frame type preheating device provided in this embodiment has a structure such as figure 1 As shown, it includes a preheating device track 1 and a roller frame track 9 arranged in parallel, a walking trolley 3 is arranged on the preheating device track, and the lower part of the walking trolley 3 is in contact with the preheating device track 1 by installing the trolley walking wheel 2, The walking trolley 3 is provided with an electrical control cabinet, and the electrical control cabinet is provided with a temperature display instrument and a control switch connected with the preheating device and the walking roller frame with a lifting mechanism; the walking trolley 3 is provided with a preheating Device mounting frame 5, preheating device 6 is installed on the top of preheating device mounting frame, preheating device is made up of heating device and variable diameter device, and variable diameter device is made up of at least two rows of variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com